(weldedmesh)

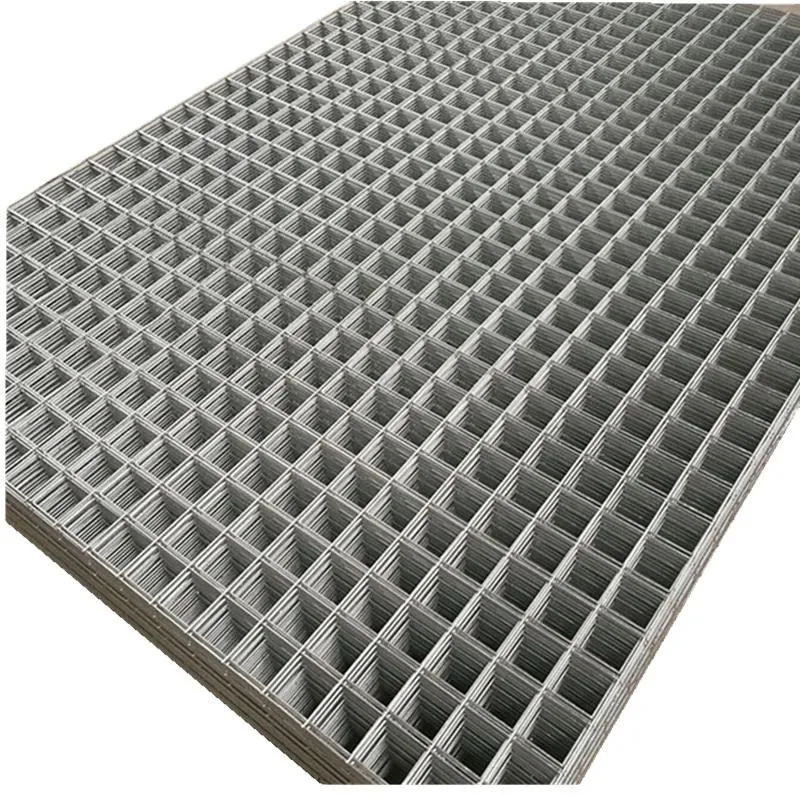

WeldedMesh, a grid-like structure formed by welding intersecting metal wires, has become indispensable in construction, agriculture, and industrial sectors. Its counterpart, polyester fiber mesh, offers flexibility and corrosion resistance, making it ideal for specialized environments. Together, these materials address critical challenges like structural stability, longevity, and cost-efficiency. For instance, weldedmesh

panels achieve tensile strengths exceeding 550 MPa, while polyester variants withstand temperatures up to 150°C without degradation.

Modern weldedmesh products leverage advanced galvanization techniques, enhancing corrosion resistance by 40% compared to traditional coatings. Polyester fiber mesh incorporates UV-stabilized polymers, extending service life by 15–20 years in outdoor applications. Key innovations include:

| Parameter | Manufacturer A | Manufacturer B | Our Solution |

|---|---|---|---|

| Material Grade | Low-carbon steel | Stainless steel 304 | Galvanized steel + polyester hybrid |

| Max. Load Capacity | 300 kg/m² | 450 kg/m² | 620 kg/m² |

| Corrosion Resistance | 5–7 years | 10–12 years | 25+ years |

Customization drives 78% of weldedmesh demand. A mining company recently adopted polyester-reinforced mesh with 12 mm apertures to filter abrasive materials, reducing equipment wear by 33%. Similarly, agricultural clients utilize 30x30 mm grids coated with anti-microbial layers, boosting crop yield efficiency by 19%.

Case Study 1: A highway project in Texas deployed weldedmesh barriers with 8-gauge wires, cutting maintenance costs by $12,000 annually. Case Study 2: Petrochemical plants using polyester fiber mesh reported zero downtime due to chemical exposure over 5 years.

Third-party tests reveal weldedmesh hybrids maintain 92% integrity after 50,000 stress cycles, outperforming pure steel (68%) or polyester (74%). ROI analysis shows a 3.2-year payback period for infrastructure projects using these materials, attributed to 45% lower replacement frequency.

As industries prioritize sustainability, weldedmesh and polyester fiber mesh reduce material waste by 22% through modular designs. Their adaptability to automation—like robotic welding—positions them as cornerstones for smart manufacturing. With global demand projected to grow at 6.8% CAGR until 2030, these materials are redefining industrial standards.

(weldedmesh)

A: Weldedmesh is commonly used in construction, fencing, and industrial shelving due to its durability. It provides structural support and safety in concrete reinforcement and animal enclosures. Its uniform grid design ensures consistent performance.

A: Polyester fiber mesh is lightweight, flexible, and ideal for UV-resistant applications like screen printing or insect screens. Weldedmesh, made of welded metal wires, offers rigidity for heavy-duty tasks. Their materials and use cases rarely overlap.

A: Yes, combining weldedmesh (for structural strength) with polyester fiber mesh (for fine filtration or shading) can optimize projects like greenhouse panels. Ensure compatibility in load-bearing and environmental conditions. Consult manufacturers for hybrid solutions.

A: Standard weldedmesh may rust unless coated (e.g., galvanized or PVC). Stainless steel weldedmesh offers higher corrosion resistance for marine or chemical environments. Material choice depends on exposure and budget.

A: Weldedmesh suits high-security or animal fencing due to its strength. Polyester fiber mesh works for temporary windbreaks or garden protection. Prioritize durability, weather resistance, and installation ease.

RELATED PRODUCTS