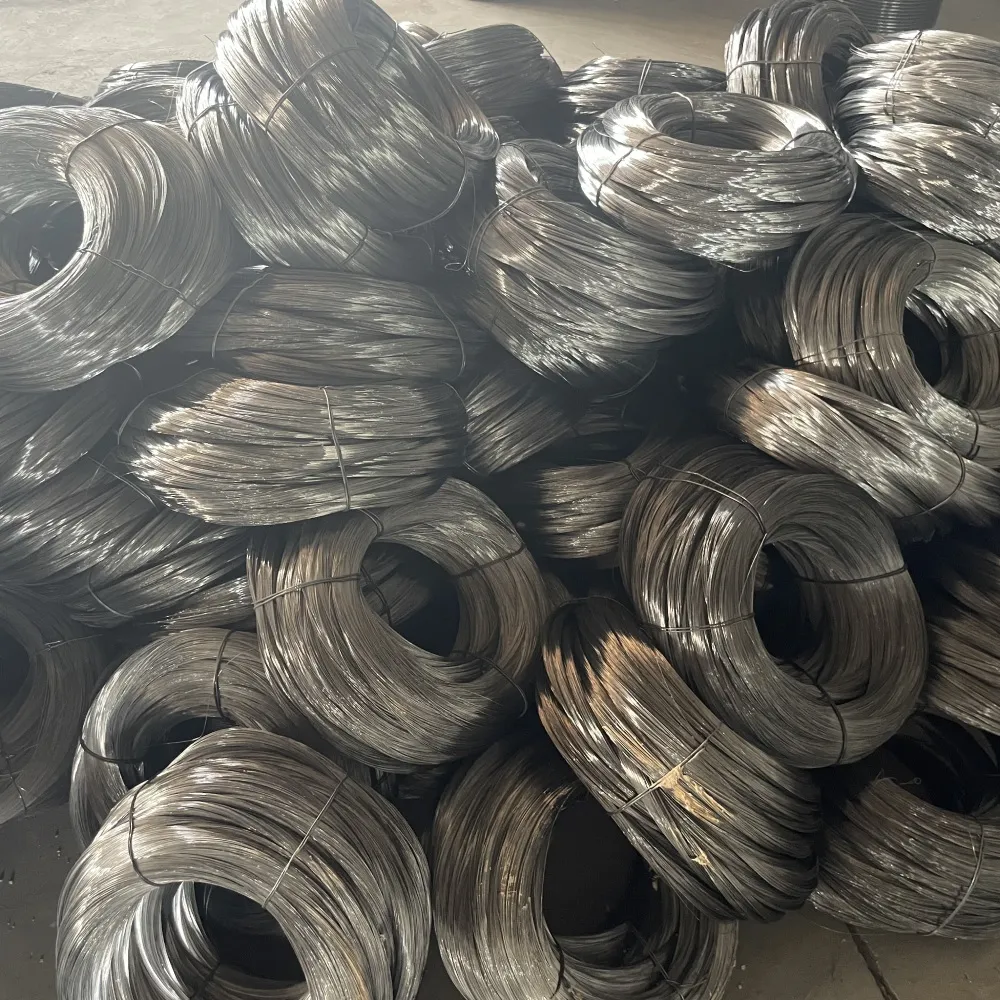

Black iron wire has good elasticity and flexibility, and its softness and hardness can be controlled during the annealing process. It is made of high-quality iron wire and is mainly used in the construction industry for binding wire and tying wire.

The packaging of black iron wire is the same as that of galvanized wire. It is divided into plastic lining and hemp outside, and plastic lining and braiding outside. First, wrap the wire in a circle with a thin layer of plastic, and then wrap it in a sack or woven bag !

|

Wire diameter

|

0.7- 4 mm

|

|

Tension strength MPA

|

315~430

|

|

breakdown point MPA

|

195

|

|

Elongation %

|

33

|

|

Roll weight

|

1kg , 2kg , 5kg , 10kg , 50kg

|

What Is Black Iron Wire Used For?

Black iron wire is widely recognized for its versatility in both construction and industrial applications. In construction, it is primarily used as iron annealed black binding wire for tying rebar, securing scaffolding, and reinforcing concrete structures. Its elasticity and flexibility make it an indispensable tool for ensuring stability during high-pressure building tasks.

Beyond construction, black iron wire is extensively applied in agriculture. Farmers use it to secure fencing, trellises, and irrigation systems because it can withstand outdoor stress while maintaining tension. The smooth surface prevents damage to plants and tools, offering both functionality and safety in agricultural setups. This adaptability is why black iron wire is often purchased in bulk by farms and large-scale agricultural suppliers.

In the industrial sector, black iron wire is favored for packaging and bundling heavy goods. Its durability ensures that bundles of steel pipes, machinery parts, or lumber stay tightly secured during transport and storage. The wire’s strength reduces the risk of material shifting, which is critical in maintaining product safety and efficiency in logistics.

Additionally, black iron wire finds use in smaller, everyday applications. From crafting and metalwork to household fixes, its bendability makes it suitable for temporary repairs and creative projects. The combination of strength, elasticity, and multi-purpose usability highlights why iron wire is a must-have across industries.

How Can Iron Annealed Black Binding Wire Improve Efficiency On-Site?

Using iron annealed black binding wire can dramatically streamline construction workflows. Its flexibility allows workers to twist and bind materials quickly without requiring excessive effort or additional tools. This is particularly useful when binding multiple rebar rods in reinforced concrete, where traditional rigid wires could slow down the process and compromise alignment.

The wire’s elasticity also reduces material fatigue. Unlike brittle wires that snap after repeated bending, black iron wire maintains structural integrity even after multiple twists and turns. This durability translates to fewer interruptions on the job, minimizing downtime and improving overall productivity.

Moreover, the smooth finish of iron wire prevents snagging on gloves or other construction materials. Workers can handle longer lengths safely, reducing the risk of minor injuries or project delays. The combination of strength, flexibility, and safety makes it an indispensable tool for construction teams handling demanding tasks.

Choosing a certified supplier like SHENZHOU TIKE METAL CO., LTD ensures access to iron annealed black binding wire that meets consistent quality standards, providing a reliable solution for large-scale projects where speed and efficiency matter.

Is Black Iron Wire Strong?

Yes, black iron wire is exceptionally strong, making it a trusted material in demanding environments. Its tensile strength allows it to endure repeated bending and twisting, which is why iron annealed black binding wire is the standard choice for tying steel reinforcement in concrete structures. Its durability ensures that rebar remains firmly in place during pouring and curing, preventing structural weaknesses.

One of the defining strengths of iron wire lies in its resistance to fatigue. While some wires may break down under constant manipulation, black iron wire maintains its integrity over time. This resilience is especially valuable in projects where long-term stability is critical, such as bridge construction, industrial facilities, or heavy scaffolding installations. Contractors can depend on it to perform consistently in environments with heavy loads and constant pressure.

The wire’s strength is also coupled with flexibility, which makes it unique compared to rigid alternatives. It can bend and hold shape while still maintaining tension, ensuring that tied materials stay securely fastened. This balance of toughness and elasticity allows workers to achieve both precision and reliability in their tasks.

In practical terms, the strength of black iron wire reduces material waste and replacement costs. Because it does not snap easily and performs reliably in harsh conditions, procurement managers favor it for large-scale projects where consistency and durability directly impact productivity.

Is Black Iron Wire Non-toxic?

Yes, black iron wire is considered non-toxic and safe for use in construction, agriculture, and general industrial applications. Unlike materials that may release harmful chemicals, this wire is simply annealed and surface-treated, making it safe to handle during binding, twisting, or tying tasks. Workers can use iron annealed black binding wire on construction sites without concern for hazardous emissions, which is crucial for maintaining safe working conditions.

In agricultural applications, the non-toxic nature of iron wire ensures that it does not harm plants, soil, or water systems. Farmers rely on it for binding crops, supporting vines, and securing fencing without fear of contaminating their produce. This property makes it especially popular in eco-sensitive projects where maintaining natural integrity is a priority.

The wire also poses no toxic threat when used in industrial packaging. Bundling materials with black iron wire does not release harmful residues, ensuring that goods remain uncontaminated during storage and shipping. Its clean surface and durable nature add to its practicality in industries where product safety is critical.

Moreover, the fact that black iron wire is safe to use contributes to its reputation as a sustainable binding material. Combined with its recyclability, it offers an environmentally friendly alternative to synthetic binding options that may leave harmful residues. This makes it not only practical but also a responsible choice for large-scale projects.