In today's dynamic industrial and commercial sectors, the demand for adaptable and robust perimeter security solutions is paramount. From bustling construction sites to large-scale public events and critical infrastructure projects, the need for effective crowd control, asset protection, and safety demarcation cannot be overstated. This is where high-quality temporary fencing systems, particularly those meeting stringent Australian standards, come into play. The market for these essential barriers is experiencing significant growth, driven by an increasing emphasis on site safety regulations, efficiency in project management, and the versatility offered by modular systems. Specifically, aus temp fencing has emerged as a cornerstone solution, providing unparalleled ease of deployment, durability, and compliance. This comprehensive guide delves into the technical intricacies, application diversity, and strategic advantages of modern temporary fencing solutions, including specific insights into how specialized manufacturers are addressing the evolving needs of various industries. We will explore the characteristics that set these fences apart, such as the resilience of the materials used in manufacturing wire mesh fence panels, and the robust engineering behind strong wire fencing systems designed for demanding environments. Understanding these elements is crucial for project managers, procurement specialists, and safety officers aiming to optimize their operational security and compliance.

The evolution of temporary fencing has moved beyond mere barriers; it now encompasses sophisticated engineering designed for rapid deployment, superior stability, and extended lifespan. Modern systems are engineered to withstand harsh environmental conditions, resist corrosion, and deter unauthorized access effectively. This involves careful consideration of material science, structural design, and modularity to ensure components interlock seamlessly, providing a continuous and secure boundary. The versatility of solutions like aus temp fencing allows for their deployment across a myriad of applications, from securing urban construction zones to managing perimeters in remote mining operations or agricultural settings requiring robust wire livestock fencing. This adaptability significantly reduces lead times for site establishment and demobilization, contributing to overall project efficiency and cost-effectiveness. Furthermore, the emphasis on reusability and recyclability aligns with global sustainability initiatives, offering an environmentally responsible choice for temporary security needs. As industries continue to evolve, the technology and application of temporary fencing will undoubtedly advance, cementing its role as an indispensable tool for safe and efficient project execution.

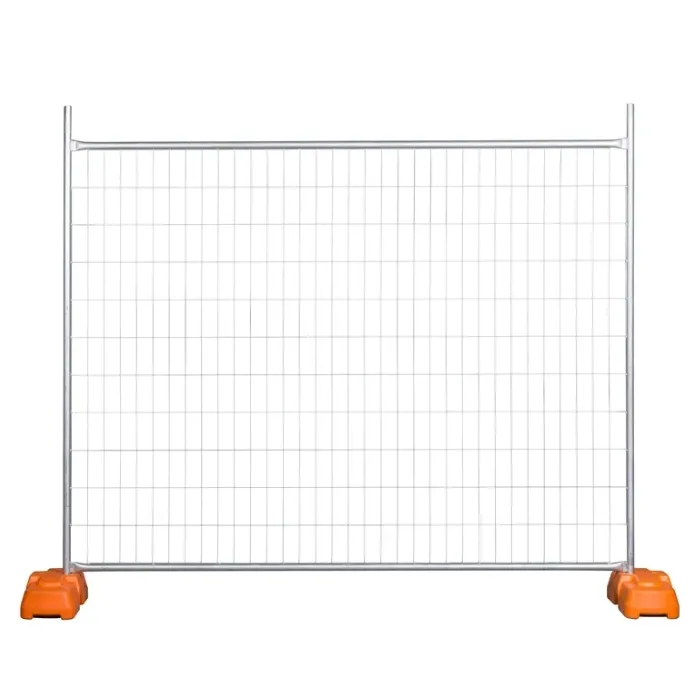

Understanding the core technical specifications of aus temp fencing is essential for ensuring optimal performance and compliance with project requirements. These fences are typically constructed from high-quality, galvanized steel, known for its exceptional strength-to-weight ratio and superior resistance to corrosion, a critical factor given Australia's diverse climatic conditions. The standard panel dimensions, mesh configuration, and pipe diameters are designed to provide a robust yet easily deployable barrier. Key parameters include the overall panel height and width, the diameter of the vertical and horizontal wires within the mesh, and the precise size of the mesh openings. These elements collectively determine the fence's rigidity, wind resistance, and anti-climb properties. The frame, typically made from heavy-duty galvanized pipe, offers foundational stability, with various foot options available to suit different ground conditions, from concrete blocks for hard surfaces to spiked feet for soft ground.

| Parameter | Typical Specification | Benefit/Purpose |

|---|---|---|

| Panel Height | 1.8m to 2.1m (approx. 6ft to 7ft) | Standard security height for deterrence and containment. |

| Panel Width | 2.4m (approx. 8ft) | Optimal for rapid installation and coverage of large areas. |

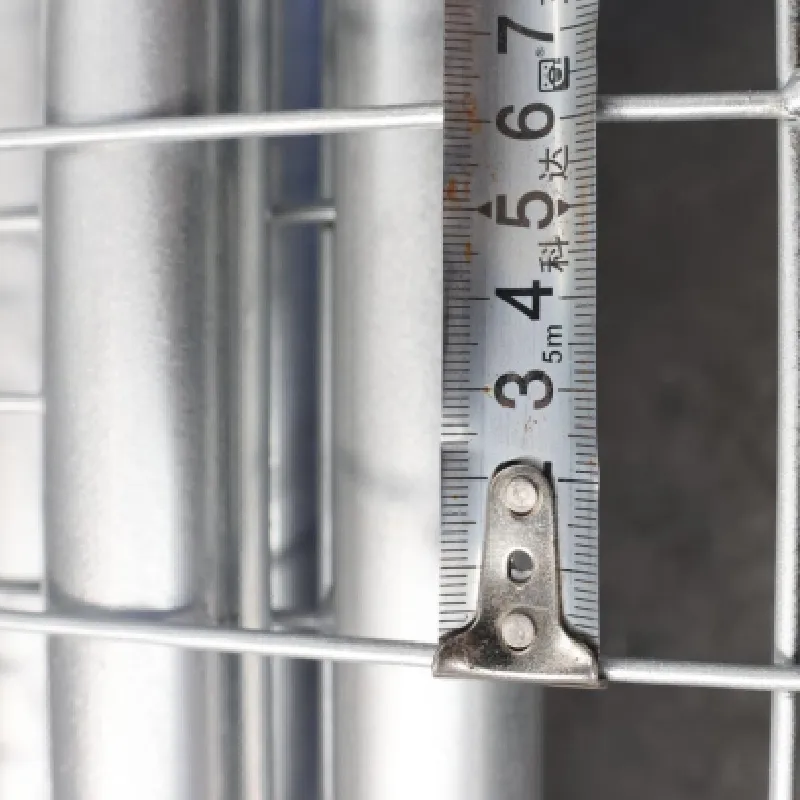

| Wire Diameter | 3.0mm to 5.0mm (0.12in to 0.20in) | Ensures mesh rigidity and resistance to cutting or bending. |

| Mesh Opening | 60x150mm (2.4x5.9in) or 75x150mm (3x5.9in) | Optimal for anti-climb properties while maintaining visibility. |

| Frame Pipe Diameter | 32mm to 48mm (1.26in to 1.89in) | Provides structural integrity and support for the mesh panel. |

| Finish | Hot-dip Galvanized | Superior corrosion resistance, extended service life. |

| Weight (per panel) | Approx. 20-25 kg (44-55 lbs) | Balancing portability with stability. |

The galvanization process, typically hot-dip galvanizing, applies a thick, durable zinc coating that acts as a sacrificial layer, protecting the steel core from rust and environmental degradation. This significantly extends the service life of the fence, reducing the frequency of replacement and maintenance, which translates into long-term cost savings. The selection of specific wire diameters and mesh openings directly impacts the fence's security efficacy, with smaller openings providing better anti-climb characteristics and greater resistance to unauthorized cutting tools. These detailed technical parameters underscore the engineering precision involved in manufacturing reliable and compliant aus temp fencing solutions, ensuring they meet the rigorous demands of various site environments.

The production of high-quality aus temp fencing is a multi-stage process that combines advanced manufacturing techniques with stringent quality control to ensure product durability and performance. It begins with the careful sourcing of raw materials, primarily high-grade low-carbon steel wires and structural pipes, which meet specific chemical composition and mechanical property standards. These materials are chosen for their ductility, weldability, and ability to withstand the galvanization process. The initial steps involve precision wire drawing to achieve the desired wire diameters, followed by automated mesh welding. In this critical phase, the individual wires are resistance-welded at each intersection, forming a robust wire mesh fence panel with consistent mesh openings and superior joint strength. This welding process is meticulously controlled to prevent weak points and ensure the structural integrity of the entire panel.

Simultaneously, the steel pipes for the fence frames undergo precision cutting and bending to create the necessary rectangular or square profiles. These frame sections are then meticulously welded to the wire mesh panels, forming a complete fence panel unit. The welding techniques employed, often including MIG or TIG welding, are selected for their ability to create strong, clean, and durable joints that can withstand external forces. Following fabrication, the entire fence panel undergoes thorough cleaning and degreasing, preparing its surface for the crucial galvanization process. Hot-dip galvanizing, a widely adopted method, involves immersing the fabricated steel panel into a bath of molten zinc. This process creates a metallurgically bonded coating that offers exceptional corrosion resistance, superior to electro-galvanizing, significantly extending the fence's lifespan, even in harsh, saline, or industrial environments typical of petrochemical or metallurgical sites. This protective layer ensures the fence maintains its structural integrity and aesthetic appeal for years, contributing to the product's overall cost-effectiveness. The final stage involves rigorous quality inspection, adhering to international standards such as ISO 9001 and often specific regional standards like AS 4687-2007 (Temporary Fencing and Hoardings), verifying dimensions, weld integrity, galvanization thickness, and overall finish. This comprehensive quality assurance ensures each panel delivers the expected performance and reliability, offering a robust, strong wire fencing solution built for longevity and repeated use, thereby enhancing its value for diverse applications in sectors like municipal works and water supply and drainage projects.

The adaptability and robust design of aus temp fencing make it an indispensable asset across a broad spectrum of industries and application scenarios. Its primary utility lies in establishing secure perimeters quickly and efficiently, safeguarding personnel, equipment, and the public. In the construction sector, temporary fences are crucial for delineating work zones, preventing unauthorized access to hazardous areas, managing pedestrian traffic around building sites, and securing valuable materials and tools overnight. Their modular nature allows for easy reconfiguration as project phases evolve, providing flexibility unmatched by permanent structures. Beyond construction, these fences are widely employed in event management, from music festivals and sporting events to public gatherings and temporary exhibitions. Here, they serve to control crowd flow, create queue lines, secure VIP areas, and manage access points, ensuring public safety and orderly operations. The ease of installation and dismantling makes them ideal for short-term deployments, minimizing logistical complexities.

Moreover, the utility of aus temp fencing extends to diverse industrial and environmental applications. In mining and quarrying operations, they are used to secure blast zones, cordon off unstable ground, and create safe pathways for heavy machinery. For agricultural and livestock management purposes, specific configurations of wire livestock fencing provide temporary enclosures for rotational grazing, animal containment during events, or delineating property lines, offering a strong wire fencing solution without the commitment of permanent structures. Utility companies frequently use these fences to secure substations, cable laying sites, and other critical infrastructure undergoing maintenance or construction. Emergency services deploy them to establish incident perimeters or create temporary shelters. The inherent design of these fences, particularly the wire mesh fence panels, ensures visibility while maintaining a high level of security, making them suitable for public-facing applications where monitoring is key. Their robust construction and corrosion resistance also make them suitable for use in harsh environments, from coastal areas to arid outback regions, offering reliable performance regardless of the conditions. This broad applicability underscores the critical role of well-engineered temporary fencing in supporting safety, security, and operational efficiency across a multitude of sectors.

The technical advantages of well-engineered aus temp fencing extend far beyond basic perimeter demarcation, offering significant operational benefits and cost efficiencies. Foremost among these is their exceptional durability and corrosion resistance. The hot-dip galvanization process, applied after fabrication, creates a zinc coating that is metallurgically bonded to the steel, providing a sacrificial layer that protects against rust, even in abrasive environments or saline conditions. This ensures a significantly longer service life compared to painted or pre-galvanized options, minimizing the need for frequent replacements and maintenance. Furthermore, the robust construction, featuring high-strength wire mesh fence panels and heavy-duty galvanized pipe frames, provides superior structural integrity. This makes them highly resistant to impact, strong winds, and attempts at forced entry, classifying them as a truly strong wire fencing solution suitable for demanding security needs.

Another critical advantage is the rapid deployment and ease of installation. Unlike permanent fencing that requires extensive ground preparation and skilled labor, temporary fencing systems are designed for quick setup and dismantling. The modular panels interlock easily with clamps and base blocks, allowing for large perimeters to be erected or reconfigured in a matter of hours with minimal tools. This efficiency significantly reduces labor costs and project timelines, contributing to overall operational agility. The reusability of these systems also offers substantial environmental and economic benefits; panels can be repeatedly deployed across different projects, reducing material waste and embodying an energy-efficient approach to site security. Moreover, compliance with Australian standards (e.g., AS 4687-2007) ensures that these fences meet rigorous safety and performance criteria, providing peace of mind for site managers and regulatory bodies. The design typically incorporates anti-climb mesh patterns, further enhancing security. For applications requiring specific animal control, the robust wire livestock fencing variants offer reliable containment. This combination of durability, rapid deployment, reusability, and adherence to high safety standards positions aus temp fencing as a superior choice for a wide array of temporary security and demarcation needs.

Choosing the right manufacturer for aus temp fencing is a critical decision that impacts not only the quality and longevity of the product but also the efficiency and safety of your projects. While many suppliers offer temporary fencing, discerning buyers should look beyond initial price points to evaluate key aspects such as material quality, manufacturing processes, adherence to industry standards, and the breadth of customization options. Reputable manufacturers prioritize the use of virgin steel and a thorough hot-dip galvanization process, ensuring superior corrosion resistance and structural integrity, differentiating their products from those using recycled or pre-galvanized materials that may compromise lifespan. Furthermore, a manufacturer's commitment to ISO-certified quality management systems and adherence to specific Australian standards, like AS 4687-2007, are clear indicators of reliability and performance consistency. Assess their expertise in producing not just standard wire mesh fence panels, but also specialized strong wire fencing variants designed for more robust applications, such as high-security sites or challenging terrain.

Beyond standard offerings, the capacity for customization is a significant differentiator. Leading manufacturers understand that not all projects fit a generic mold. They offer bespoke solutions tailored to unique site requirements, including variations in panel height and width, different mesh configurations (e.g., smaller openings for enhanced security or specific wire livestock fencing needs), custom gate integration (pedestrian gates, vehicle gates, sliding gates), and specialized foot options for diverse ground conditions. Some may even provide color powder coating options for branding or aesthetic purposes, especially for public-facing events. A robust manufacturer will also offer comprehensive technical support, guiding clients through selection, installation, and maintenance, ensuring the longevity and optimal performance of the fencing system. When comparing manufacturers, inquire about their service history, past project references, and their capacity for rapid supply and logistical support, particularly for large-scale or urgent deployments. This holistic approach to evaluation ensures you partner with a provider that delivers not just a product, but a complete, reliable, and tailored temporary security solution.

The practical effectiveness of aus temp fencing is best illustrated through real-world application scenarios, where these systems have significantly contributed to project safety, efficiency, and security. Consider a major urban high-rise construction project, where pedestrian traffic is heavy and site boundaries are constantly shifting. In such a dynamic environment, the rapid deployment capability of temporary fencing allows for quick reconfigurations of the perimeter as cranes move, materials are delivered, and new sections of the building rise. The robust wire mesh fence panels deter unauthorized entry, protecting the public from falling debris and securing valuable construction equipment overnight. The reusability of these panels means they can be transferred from one phase of the project to the next, and eventually to a new site, demonstrating significant cost savings and reduced environmental impact compared to single-use barriers. For instance, a complex, multi-year infrastructure development, involving extensive road works and utility upgrades, leveraged hundreds of meters of aus temp fencing to manage traffic flow, secure excavations, and establish safe working corridors for personnel and machinery, ensuring compliance with strict safety regulations and minimizing public disruption throughout the project's duration.

Another compelling case study involves large-scale public events, such as national sporting championships or major music festivals, which attract tens of thousands of attendees. For these events, perimeter security and crowd management are paramount. Strong wire fencing, specifically designed for temporary setups, is deployed to create ticketed entry points, delineate specific zones (e.g., food courts, first aid stations, VIP areas), and establish emergency exit routes. The high visibility offered by the wire mesh design allows security personnel to monitor crowds effectively, while the fence's strength provides a reliable barrier. The ease of installation and dismantling post-event drastically reduces logistical overheads and minimizes disruption to public spaces. Furthermore, in agricultural settings, specific requirements for animal control have seen the rise of dedicated wire livestock fencing solutions. For example, a farming cooperative implementing rotational grazing utilized modular aus temp fencing systems to quickly create temporary paddocks, allowing for efficient land management and animal welfare without the need for permanent, costly fixed fencing. These examples underscore the versatility, operational benefits, and critical role that well-designed temporary fencing plays in ensuring safety, security, and efficiency across diverse industrial and commercial landscapes.

Building and maintaining trust with B2B clients in the temporary fencing sector hinges on a steadfast commitment to product quality, transparent operational processes, and reliable customer support. Reputable manufacturers of aus temp fencing adhere to rigorous quality assurance protocols that span the entire production lifecycle, from raw material inspection to final product testing. This includes strict compliance with international standards such as ISO 9001 for quality management systems, ensuring consistency in manufacturing processes and product specifications. For instance, each batch of steel undergoes chemical analysis and mechanical testing to verify its strength and suitability for galvanization. Weld integrity of the wire mesh fence panels is routinely checked, and the thickness and uniformity of the hot-dip galvanized coating are meticulously measured to guarantee superior corrosion resistance and longevity, often exceeding Australian standards like AS 4687. A comprehensive warranty commitment, often extending for several years, provides an additional layer of assurance, demonstrating the manufacturer's confidence in their product's durability and performance.

Beyond product quality, reliable delivery and responsive customer support are paramount. Manufacturers with robust supply chain management can offer predictable delivery cycles, typically within 2-4 weeks for standard orders, with options for expedited shipping to accommodate urgent project timelines. Global logistics capabilities ensure that products can reach diverse locations efficiently. Technical support, including pre-sales consultation, installation guidance, and post-sales assistance, is crucial. This support extends to addressing specific challenges related to site conditions, advising on the optimal configuration of strong wire fencing for high-security areas, or recommending the best wire livestock fencing solutions for agricultural applications. This comprehensive approach to quality, logistics, and customer service solidifies a manufacturer's trustworthiness and forms the bedrock of long-term B2B partnerships.

The demand for secure, efficient, and versatile temporary fencing solutions continues to rise across various industries, making aus temp fencing an indispensable asset for modern project management and site security. Engineered with precision and manufactured from high-grade galvanized steel, these systems offer a superior combination of durability, rapid deployability, and compliance with stringent safety standards. From urban construction sites requiring robust perimeter control to large-scale events demanding efficient crowd management and agricultural settings in need of reliable wire livestock fencing, the applications are diverse and critical. The technical advantages, including exceptional corrosion resistance, high structural integrity, and reusability, translate into significant operational efficiencies and long-term cost savings. By understanding the detailed manufacturing processes, technical specifications, and the importance of authoritative sourcing, businesses can make informed procurement decisions that enhance safety, optimize workflows, and build trust in their operational capabilities. The ongoing evolution of this vital infrastructure underscores its enduring value as a cornerstone of temporary site security and control.

RELATED PRODUCTS