In the intricate world of modern architecture, industrial design, and acoustic management, the demand for aesthetically pleasing yet highly functional materials is consistently on the rise. Among these, decorative perforated metal sheets stand out as a versatile solution. These sheets, characterized by their diverse hole patterns and material compositions, offer an unparalleled combination of visual appeal, structural integrity, and practical benefits. Industry trends indicate a significant shift towards sustainable and customizable building materials, positioning perforated metals as a key player in green building initiatives and innovative design. The global perforated metal market size was valued at approximately USD 2.1 billion in 2022 and is projected to reach USD 3.5 billion by 2030, growing at a CAGR of 6.5%. This growth is fueled by increasing applications in construction, automotive, HVAC, and acoustics. Designers and engineers are continually exploring new ways to integrate these materials for light diffusion, ventilation, sound absorption, and privacy screening, making them indispensable for contemporary projects. Our commitment at Tikemetal is to push the boundaries of design and functionality, providing solutions that not only meet but exceed contemporary industry standards.

The adaptability of decorative perforated metal sheets extends beyond mere aesthetics, encompassing critical functional attributes such as optimized airflow, enhanced safety through anti-slip surfaces, and significant noise reduction. This duality of form and function makes them highly sought after in sectors ranging from commercial complexes to public infrastructure. Key drivers for adoption include stringent building codes necessitating improved ventilation and fire safety, alongside a burgeoning preference for bespoke architectural elements. Furthermore, the advent of advanced manufacturing techniques has expanded the possibilities for intricate patterns and precise tolerances, enabling designers to realize complex visions previously unattainable. We observe a particular surge in demand for materials that can withstand harsh environmental conditions while maintaining their aesthetic integrity, a challenge expertly met by our specialized range of corrosion-resistant and high-strength perforated solutions. The ongoing innovations in surface treatments and material alloys further broaden their applicability, ensuring that they remain at the forefront of material science for architectural and industrial applications globally.

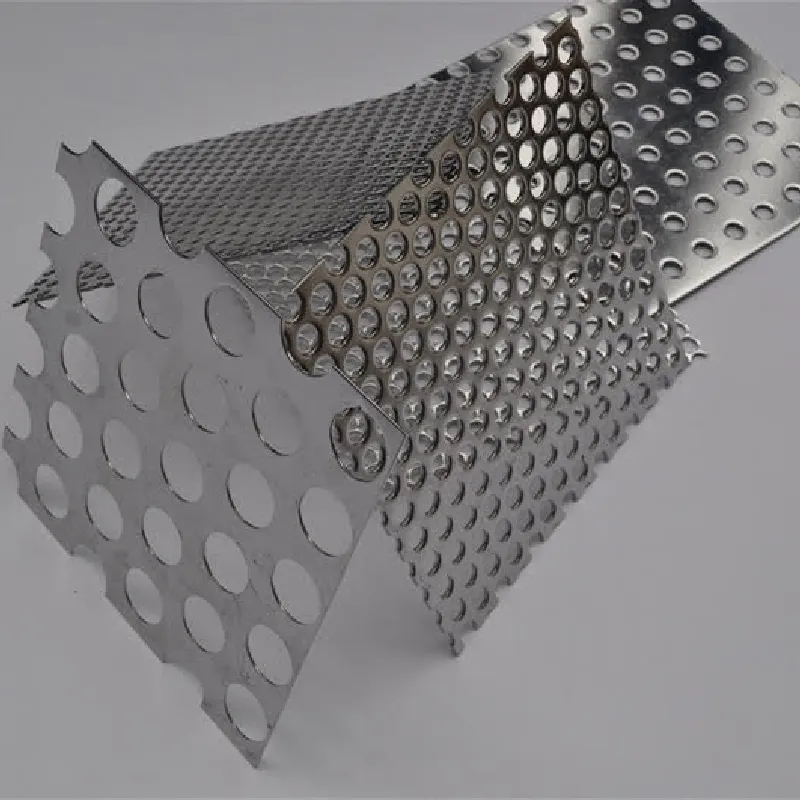

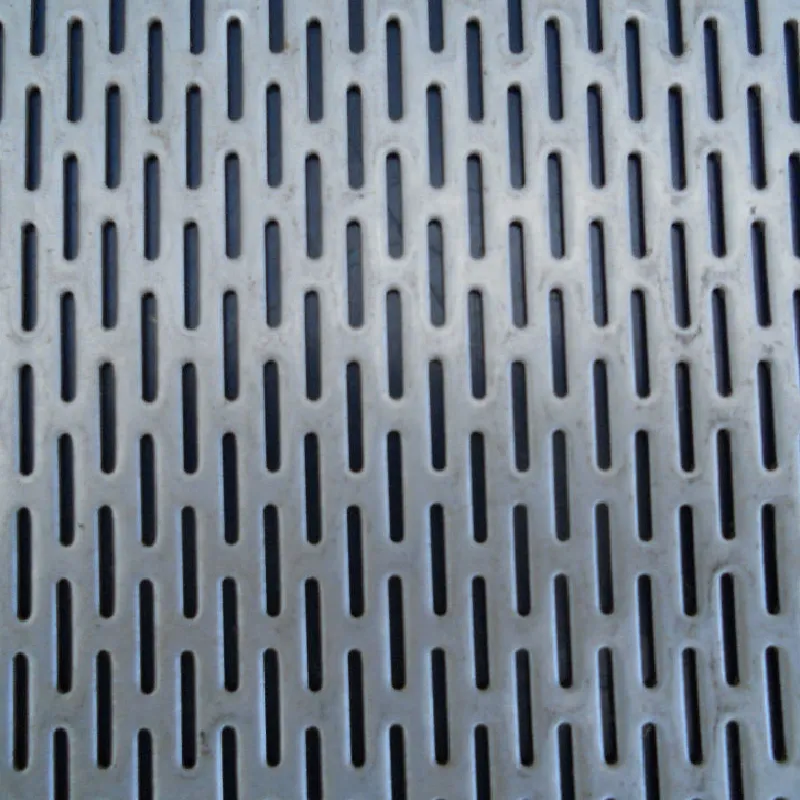

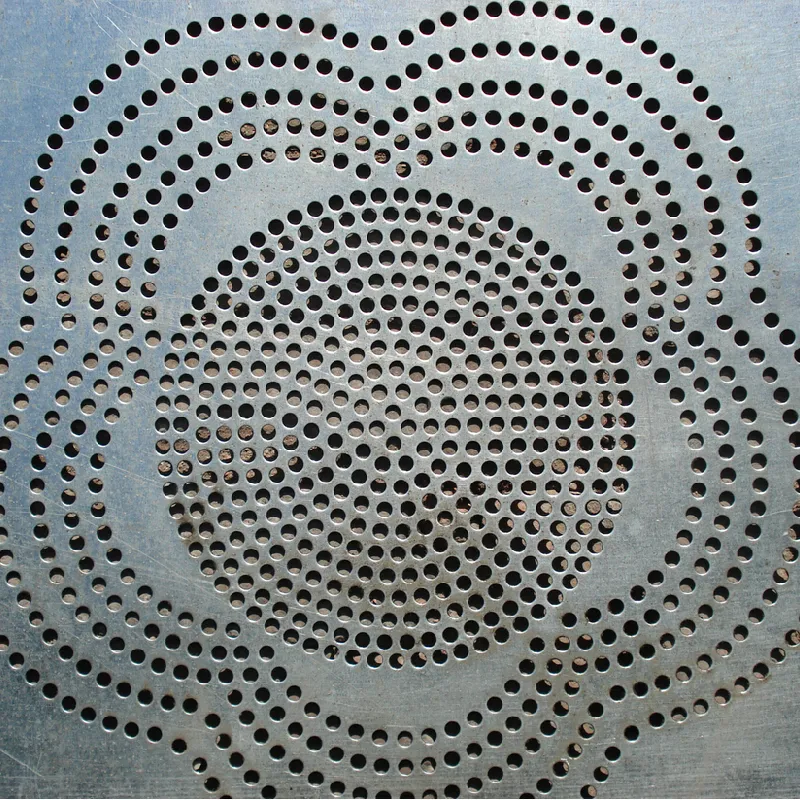

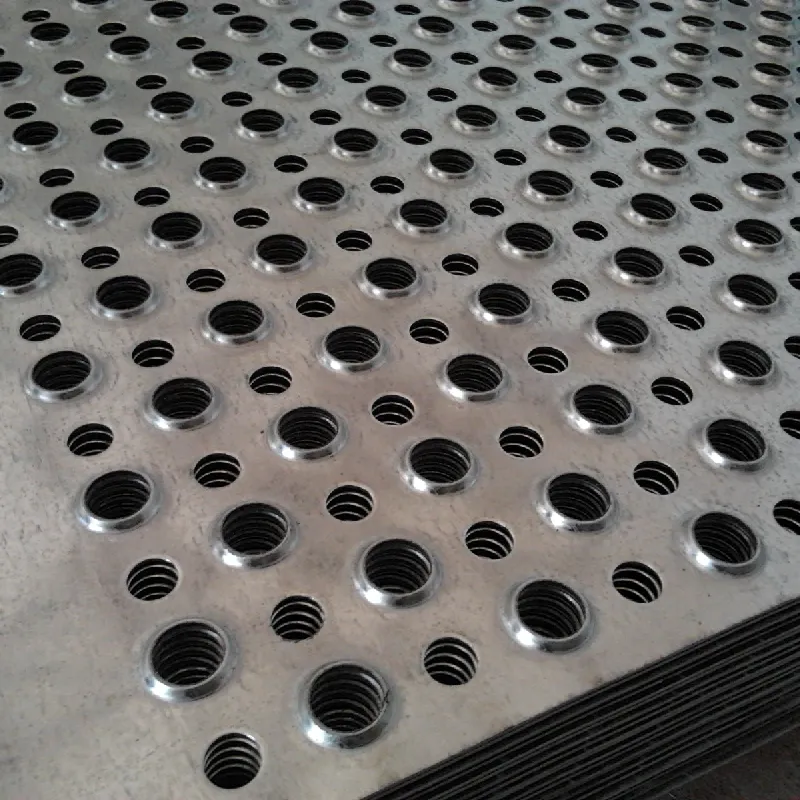

The manufacturing of decorative perforated metal sheets is a highly precise process, ensuring both aesthetic appeal and structural integrity. Typically, the process begins with selecting high-grade raw materials such as stainless steel (304, 316L), aluminum, galvanized steel, carbon steel, and copper, chosen for their specific properties like corrosion resistance, strength-to-weight ratio, and aesthetic finish. Unlike casting or forging, the primary manufacturing method for perforated sheets involves precision punching or stamping. Large, automated presses utilize custom-designed dies to create a wide array of hole patterns—round, square, slotted, hexagonal (including hex perforated metal), and custom decorative shapes—with exceptional accuracy. This method allows for precise control over hole size, spacing, and open area, which are critical parameters defining the sheet's functionality. Advanced CNC (Computer Numerical Control) technology ensures repeatability and minimizes material waste, supporting efficient large-scale production runs and bespoke orders. Each sheet undergoes rigorous inspection post-perforation, adhering to international standards such as ISO 9001:2015 for quality management, ANSI/NAAMM standards for metal products, and specific ASTM specifications for material composition and mechanical properties. This meticulous process guarantees a product that not only looks superior but also performs reliably under demanding conditions.

Post-perforation, the sheets may undergo various finishing treatments to enhance durability, aesthetics, and performance. These include powder coating for color customization and improved corrosion resistance, anodizing for aluminum sheets to create a hard, protective layer, and polishing or brushing for specific surface finishes. The service life of decorative perforated metal sheets is directly influenced by the material chosen and the environment of application; for instance, stainless steel 316L sheets can last for decades in harsh marine environments due to their superior corrosion resistance. Applicable industries are vast and include petrochemical for filtration and safety grating, metallurgy for screening and sorting, and water supply/drainage systems for strainers and diffusers. In these typical application scenarios, the advantages are evident: perforated sheets offer excellent ventilation for heat dissipation, prevent accumulation of debris, and provide robust corrosion protection, leading to significant energy savings in HVAC systems and reduced maintenance costs. Our commitment to quality ensures that every product adheres to strict specifications, providing optimal performance and longevity across diverse industrial and architectural applications.

| Parameter | Typical Range / Description | Significance |

|---|---|---|

| Material Options | Stainless Steel (304, 316, 316L), Aluminum (1100, 3003, 5052), Galvanized Steel, Carbon Steel, Copper, Brass | Determines corrosion resistance, strength, weight, and aesthetic finish. |

| Sheet Thickness | 0.5 mm - 10 mm (0.02" - 0.4") | Impacts rigidity, durability, and formability. |

| Hole Shape | Round, Square, Slotted, Hexagonal, Ornamental, Custom | Influences aesthetic pattern, light diffusion, and airflow. |

| Hole Size | 0.5 mm - 100 mm (0.02" - 4") | Affects open area, filtration capability, and visual transparency. |

| Pitch (Center Distance) | Varies (typically 1.5 - 3x hole diameter) | Determines open area and pattern density. |

| Open Area Percentage | 10% - 70% (Custom higher/lower possible) | Crucial for airflow, light transmission, and acoustic properties. |

| Sheet Size | Standard (e.g., 4'x8', 4'x10', 5'x10') or Custom up to 6000mm length | Impacts installation, waste, and design flexibility. |

| Surface Finish | Mill finish, Polished, Brushed, Anodized, Powder Coated (RAL colors available) | Enhances aesthetics, corrosion resistance, and specific functional properties. |

The technical advantages of decorative perforated metal sheets are manifold, extending far beyond their visual appeal. Their inherent design allows for superior light diffusion, mitigating glare while maximizing natural illumination, a critical feature for LEED-certified buildings aiming for energy efficiency. Furthermore, their open area facilitates excellent ventilation, essential for HVAC systems and ensuring air quality in enclosed spaces. Acoustic performance is another significant advantage; when combined with appropriate backing materials, perforated panels can effectively absorb sound, reducing noise levels in bustling environments like airports, concert halls, and office buildings. The durability and resistance to various environmental factors, including corrosion, abrasion, and impact, are paramount. For instance, stainless steel 316L, due to its molybdenum content, offers enhanced resistance against pitting and crevice corrosion in chloride environments, making it ideal for coastal or marine applications. Aluminum sheets, known for their lightweight nature and excellent strength-to-weight ratio, are preferred where weight is a critical design consideration, such as in aerospace or vehicular applications. Galvanized steel provides robust protection against rust and corrosion at a cost-effective price point, suitable for general industrial use.

Our expertise in material selection ensures that each project benefits from the optimal balance of performance, longevity, and cost-effectiveness. We guide clients through the complexities of material properties, surface treatments, and environmental factors to specify the most suitable type of decorative perforated metal sheets. For demanding applications requiring robust filtration or separation, specialized configurations like perforated wire mesh can be integrated, offering finer filtration capabilities while retaining structural integrity. The precise punching technology we employ ensures uniform hole patterns, crucial for consistent performance in filtration and ventilation. This precision also contributes to the material's aesthetic consistency, vital for large-scale architectural facades where visual uniformity is key. Our solutions are designed not just to meet the immediate functional and aesthetic requirements but also to offer long-term value through reduced maintenance and extended product life, thereby minimizing lifecycle costs. This holistic approach to material engineering and application strategy underpins our reputation as a trusted partner in providing high-quality perforated metal solutions across a spectrum of industries.

The versatility of decorative perforated metal sheets enables their application across an impressive array of industries and settings, demonstrating their functional and aesthetic adaptability. In architecture and construction, they are extensively used for building facades, sunscreens, balustrades, ceilings, and wall cladding, providing distinctive visual textures while managing light and airflow. For instance, a building facade crafted from aluminum perforated sheets can significantly reduce solar heat gain, contributing to energy efficiency, and simultaneously offer a modern, sophisticated aesthetic. In the automotive sector, these sheets find use in grille inserts, filtration components, and exhaust system parts, where airflow, heat dissipation, and sound attenuation are critical. The HVAC industry relies on them for diffusers, grilles, and filters, ensuring optimal air distribution and purification. Their ability to handle high temperatures and corrosive environments also makes them indispensable in petrochemical and metallurgical plants for screening, filtration, and protective barriers.

Beyond these major sectors, decorative perforated metal sheets are integral to diverse applications. In the agricultural industry, they are used for grain drying and sorting equipment; in food processing, for sieves and drying trays due to their hygienic properties; and in electronics, for EMI shielding and speaker grilles. Public spaces like bus stops, park benches, and waste receptacles also benefit from their durability and low maintenance requirements. Our project portfolio includes providing customized hex perforated metal panels for a major university's new library facade, chosen for its unique light diffusion properties and contemporary aesthetic. Another notable application involved supplying bespoke perforated wire mesh for noise barriers along a metropolitan highway, effectively reducing sound pollution for nearby residential areas while allowing for natural ventilation. These examples underscore our capability to deliver tailored solutions that meet specific project demands, whether for large-scale industrial infrastructure or intricate architectural details, consistently prioritizing performance, durability, and design integrity.

The demand for bespoke solutions in modern design and engineering necessitates robust customization capabilities from manufacturers of decorative perforated metal sheets. At Tikemetal, we pride ourselves on our ability to transform unique client visions into tangible products. Our customization services encompass a wide range of parameters: from specific hole patterns (including intricate geometric designs, logos, or brand-specific motifs) to precise open area percentages for optimized light, air, or sound management. We offer a vast selection of materials, thicknesses, and finishes, ensuring that the final product perfectly aligns with the project's aesthetic and functional requirements. Unlike generic suppliers, our advanced CNC punching and laser cutting technologies allow for unparalleled precision and flexibility, facilitating the creation of complex shapes and custom dimensions without compromising on material integrity or quality. This includes specialized edge configurations, bending, rolling, and welding services to deliver ready-to-install components. Our technical team works closely with architects, designers, and engineers from concept to completion, offering expert consultation on material suitability, structural considerations, and compliance with industry standards such as ASTM, EN, and JIS.

When evaluating manufacturers for decorative perforated metal sheets, several factors are critical for B2B decision-makers. Key differentiators include the breadth of product offerings, manufacturing precision, adherence to international quality standards, turnaround times, and post-sales support. While some manufacturers may offer lower initial costs, this often comes at the expense of material quality, inconsistent perforation, or limited customization options, leading to higher long-term maintenance or replacement expenses. A thorough comparison reveals that reputable manufacturers like Tikemetal invest significantly in cutting-edge technology and skilled craftsmanship, resulting in products with superior longevity and performance. Our transparent pricing structure, detailed technical specifications, and commitment to timely delivery differentiate us in a competitive market. We also provide comprehensive material certifications and performance data, reinforcing client confidence in our products. This holistic approach ensures that our clients receive not just a product, but a complete, reliable, and cost-effective solution tailored to their exact needs, mitigating risks associated with less experienced or less equipped suppliers.

Real-world application case studies vividly illustrate the practical benefits and transformative potential of decorative perforated metal sheets. One compelling example involves a recent collaboration with a leading architectural firm for a high-profile commercial complex in downtown Vancouver. The project required an external cladding system that offered both aesthetic appeal and advanced solar shading capabilities. We provided custom-fabricated aluminum decorative perforated metal sheets with a unique square perforation pattern and a specialized powder coating in a metallic bronze finish. This solution not only contributed significantly to the building's striking visual identity but also reduced indoor temperatures by an average of 3-5°C during peak summer months, leading to an estimated 15% reduction in cooling energy consumption. The architect praised our meticulous attention to detail and ability to deliver complex designs within stringent timelines. Another notable case involved a petrochemical facility requiring durable and corrosion-resistant flooring and grating for elevated platforms. Our stainless steel perforated wire mesh was chosen for its anti-slip properties and superior resistance to chemical exposure, enhancing worker safety and significantly extending the lifespan of the flooring system compared to traditional materials. This project highlighted our ability to meet rigorous industrial safety and performance standards.

Customer feedback consistently reinforces the value we bring to complex projects. A project manager from a major construction company recently commented, "Tikemetal's dedication to quality and their engineering support were instrumental in the successful completion of our sound barrier project. The hex perforated metal panels were precisely manufactured and delivered on schedule, exceeding our expectations for noise reduction and aesthetic integration with the surrounding environment." Over the past two decades, Tikemetal has successfully completed over 5,000 projects worldwide, accumulating extensive experience in diverse applications. Our long-standing relationships with clients are a testament to our consistent product quality, reliable delivery, and proactive customer support. We understand that each project presents unique challenges, and our team is committed to providing comprehensive solutions from initial design consultation through to post-installation support. Our portfolio of successful ventures spans across continents, from major urban developments to specialized industrial installations, showcasing our global reach and unwavering commitment to client satisfaction. This hands-on experience allows us to foresee potential challenges and provide innovative, practical solutions.

Building trust and ensuring reliability are paramount in the B2B sector, especially for critical components like decorative perforated metal sheets. Tikemetal stands by its products and services through a robust framework of quality assurance, transparent processes, and dedicated customer support. We are an ISO 9001:2015 certified manufacturer, a testament to our unwavering commitment to maintaining the highest standards in all aspects of production, from raw material sourcing to final inspection. Our products frequently undergo independent third-party testing to validate performance claims, including tests for material composition, tensile strength, and corrosion resistance. We maintain partnerships with leading raw material suppliers, ensuring traceability and consistency across all batches. Our service commitment is reinforced by a comprehensive warranty policy, typically covering defects in material and workmanship for 5 to 10 years, depending on the product and application. This warranty provides our clients with peace of mind, knowing that their investment is protected. We also provide clear and concise documentation for all products, including material safety data sheets (MSDS) and certificates of conformity, further enhancing transparency and reliability.

Understanding the critical timelines of B2B projects, Tikemetal offers a streamlined order processing and delivery system. Our typical delivery lead time for standard products ranges from 2-4 weeks, while custom orders may take 4-8 weeks, depending on complexity and volume. These estimates are provided transparently at the quotation stage, with real-time updates available throughout the production and logistics phases. Our dedicated customer support team is available during business hours to address any inquiries, provide technical assistance, or facilitate order modifications. We offer various support channels, including phone, email, and a dedicated online portal for tracking orders and accessing product resources. Our post-sales support includes technical guidance for installation and maintenance, ensuring the optimal performance and longevity of our decorative perforated metal sheets. With over two decades of experience and a track record of serving thousands of satisfied clients globally, our authoritative standing in the industry is built on consistent quality, technical expertise, and an unwavering commitment to client success.

Q: What is the typical lead time for custom perforated metal orders?

A: For custom orders, the lead time generally ranges from 4 to 8 weeks, depending on the complexity of the design, material availability, and order volume. Standard products usually ship within 2-4 weeks.

Q: Can your decorative perforated sheets be used for outdoor applications?

A: Absolutely. We offer materials like stainless steel (e.g., 304, 316L) and aluminum with various finishes (e.g., anodizing, powder coating) specifically designed for superior weather resistance and longevity in outdoor environments.

Q: Do you provide installation guidelines or support?

A: While we primarily supply the perforated sheets, our technical team provides comprehensive support including detailed product specifications, recommended handling procedures, and general installation guidelines to assist your contractors.

Q: What certifications do your products hold?

A: Our manufacturing processes are ISO 9001:2015 certified, and our materials comply with relevant ASTM, EN, and JIS standards. Specific product certifications and test reports are available upon request.

The evolution and widespread adoption of decorative perforated metal sheets underscore their critical role in modern industrial and architectural design. Their multifaceted benefits—ranging from aesthetic versatility and superior light management to robust structural integrity and advanced acoustic properties—make them an indispensable material for a vast array of applications. As industries continue to seek sustainable, efficient, and innovative solutions, the demand for customizable, high-performance perforated metal will only intensify. Our commitment to precision engineering, adherence to stringent quality standards, and deep understanding of material science ensures that Tikemetal remains at the forefront of this evolving market. By consistently delivering products that combine visual sophistication with unparalleled functionality, we empower our clients to achieve their most ambitious project goals. We invite you to explore our comprehensive range of products and collaborate with our experts to realize the full potential of perforated metal in your next endeavor.

RELATED PRODUCTS