In the dynamic landscape of industrial and construction materials, the demand for robust, long-lasting, and aesthetically pleasing fencing and containment solutions continues to escalate. Among the myriad options available, PVC Coated Welded Wire Mesh stands out as a superior choice, particularly in B2B applications where durability, corrosion resistance, and minimal maintenance are paramount. This material represents a significant advancement over traditional uncoated or merely galvanized wire products, offering an extended service life and enhanced performance across diverse environments. The global market for wire mesh products is experiencing steady growth, driven by increasing infrastructure development, stringent safety regulations, and a heightened focus on sustainable, long-term investments. Industries such as petrochemical, metallurgy, public utilities, and even sophisticated agricultural sectors are increasingly specifying PVC-coated variants due to their proven resilience against harsh weather conditions, chemical exposure, and mechanical wear. This comprehensive guide will delve into the intricate details of this essential material, from its precise manufacturing processes and technical specifications to its wide-ranging applications and the critical factors discerning buyers must consider for optimal procurement. We aim to equip B2B decision-makers and technical personnel with the in-depth knowledge necessary to make informed choices, ensuring the selection of products that align perfectly with their project requirements and deliver unparalleled value over their operational lifespan.

The inherent strength of welded wire, combined with the protective and aesthetic qualities of a PVC coating, creates a synergistic material ideal for demanding applications. Unlike standard wire mesh, which might succumb to rust and degradation over time, the polyvinyl chloride (PVC) layer acts as an impermeable barrier, safeguarding the underlying steel wire from moisture, chemicals, and UV radiation. This protective envelope not only extends the product's functional life but also reduces the frequency and cost of maintenance, presenting a compelling total cost of ownership (TCO) argument for businesses. Furthermore, the availability of PVC coatings in various colors allows for integration into specific architectural or environmental designs, offering both utilitarian function and visual appeal. From securing industrial perimeters to containing livestock on expansive farms, the adaptability and reliability of this product underscore its critical role in modern infrastructure and industrial operations. Understanding the underlying manufacturing excellence and adherence to international standards, such as ISO and ASTM, is crucial for evaluating product quality and ensuring long-term performance in various operational contexts, from urban development to remote industrial sites.

The production of high-quality PVC Coated Welded Wire Mesh is a multi-stage process that combines precision engineering with advanced material science to ensure superior performance and longevity. The foundational material typically consists of high-grade low-carbon steel wire or galvanized steel wire, selected for its tensile strength and inherent durability. The process commences with wire drawing, where steel rods are meticulously pulled through progressively smaller dies to achieve the desired wire diameter, ensuring uniformity and structural integrity. Following this, the wires are precisely welded using automated machinery, often through resistance welding or electric fusion welding techniques, which create strong, uniform joints at each intersection. This crucial step forms the rigid mesh structure, with precise mesh openings (aperture sizes) that meet specific application requirements. The quality of these welds is paramount, as weak joints can compromise the entire mesh's structural stability and resistance to external forces. Comprehensive quality checks, including weld strength tests and dimensional accuracy measurements, are performed at this stage to conform to industry standards such as ASTM A185 for welded steel wire fabric.

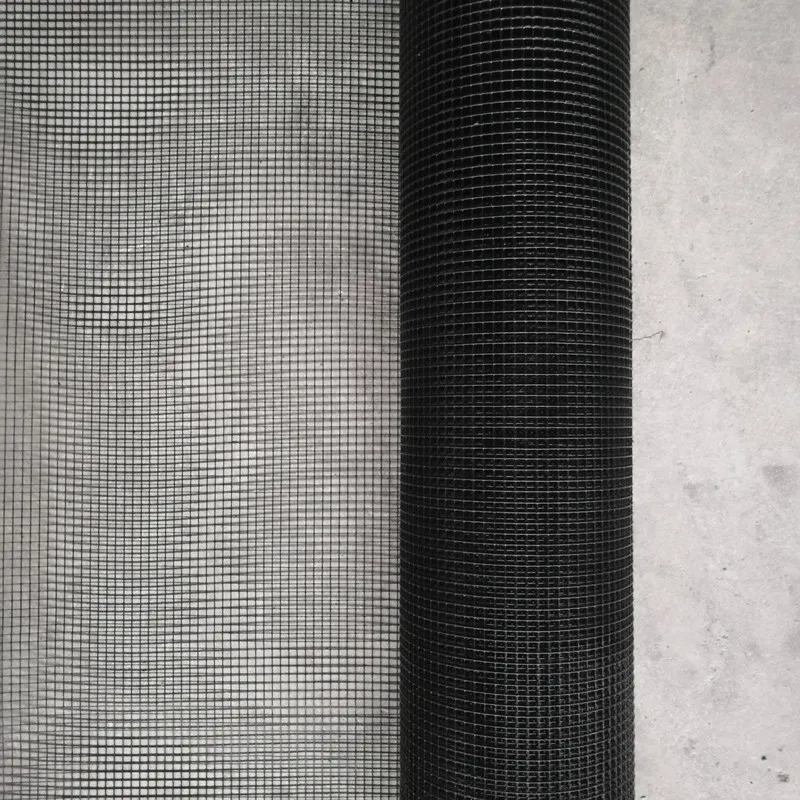

After the initial welding, the mesh undergoes a thorough cleaning process to remove any oils, dirt, or residues that might impede the PVC coating's adhesion. This often involves degreasing, pickling, and rinsing, preparing the surface for optimal bonding. The cleaned mesh is then preheated to a specific temperature, which is critical for the subsequent PVC application. The most common methods for applying the PVC coating are the fluidized bed dipping process or extrusion coating. In the fluidized bed method, the preheated mesh is immersed into a tank of finely powdered PVC resin, which fluidizes when air is passed through it. The heat of the mesh causes the PVC powder to melt and uniformly adhere to the wire surface, forming a continuous, thick layer. Alternatively, in extrusion coating, molten PVC is extruded directly onto the wire mesh as it passes through a die. Following coating, the mesh enters a curing oven, where the PVC is thermoset, ensuring a strong, durable, and uniform bond to the steel substrate. This curing process enhances the coating's elasticity, impact resistance, and UV stability. Rigorous post-coating inspections, including adhesion tests, coating thickness measurements (typically ranging from 0.4mm to 1.0mm), and visual checks for imperfections, confirm that the final PVC Coated Welded Wire Mesh meets stringent quality control standards like ISO 9001, ANSI/AWWA, and specific client specifications. This meticulous manufacturing protocol guarantees the product's enhanced resistance to corrosion, chemicals, and mechanical abrasion, extending its service life significantly in demanding environments such as those found in petrochemical, metallurgy, and water treatment industries, where equipment longevity and resistance to corrosive elements are essential for operational efficiency and safety.

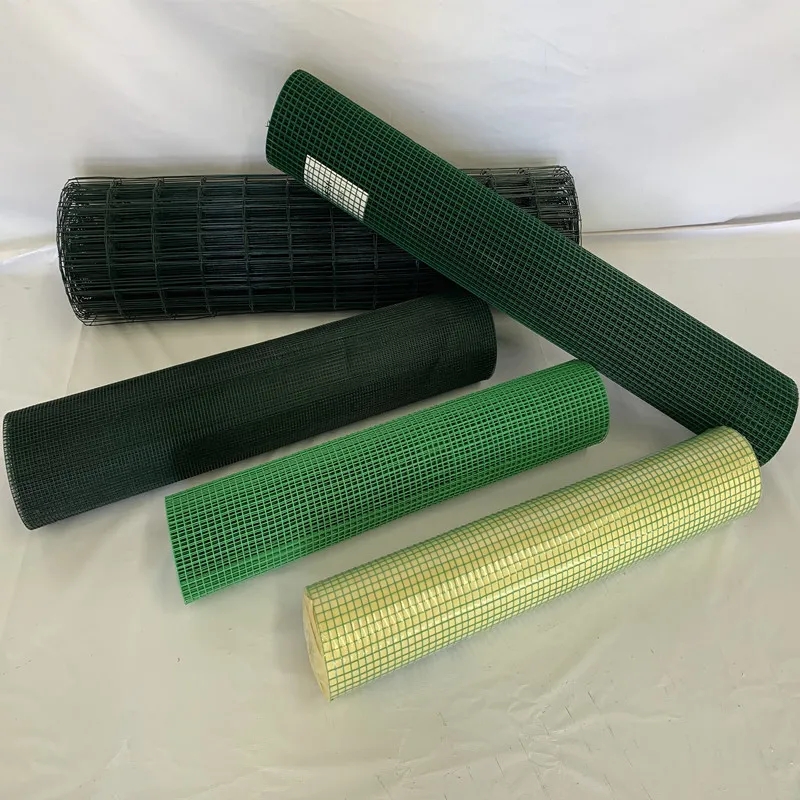

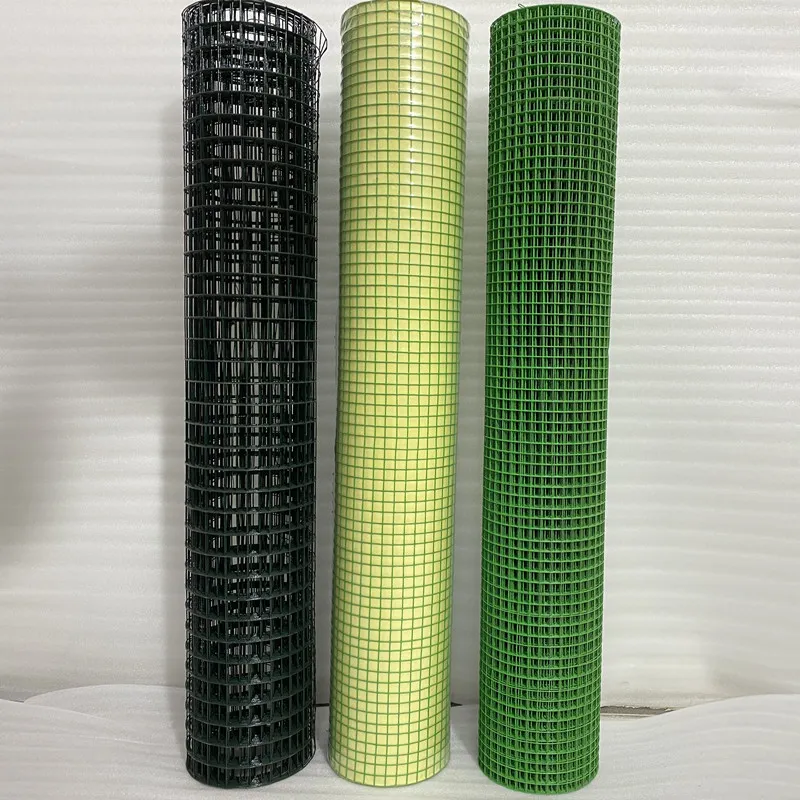

The performance and suitability of PVC Coated Welded Wire Mesh for specific industrial and commercial applications are largely determined by its precise technical specifications. Key parameters include the core wire diameter, mesh opening size (aperture), roll dimensions, PVC coating thickness, and color options. The core wire diameter typically ranges from 0.8mm to 6.0mm (approximately 22 to 6 gauge), influencing the mesh's rigidity, strength, and load-bearing capacity. A thicker core wire provides greater structural integrity, making it suitable for high-security fencing or heavy-duty industrial enclosures. Mesh opening sizes vary widely, from fine meshes like 6mm x 6mm or 12.7mm x 12.7mm for pest control or small animal enclosures to larger openings such as 50mm x 50mm or 75mm x 75mm used in general security fencing or garden boundaries. The choice of mesh size directly impacts visibility, containment effectiveness, and material usage.

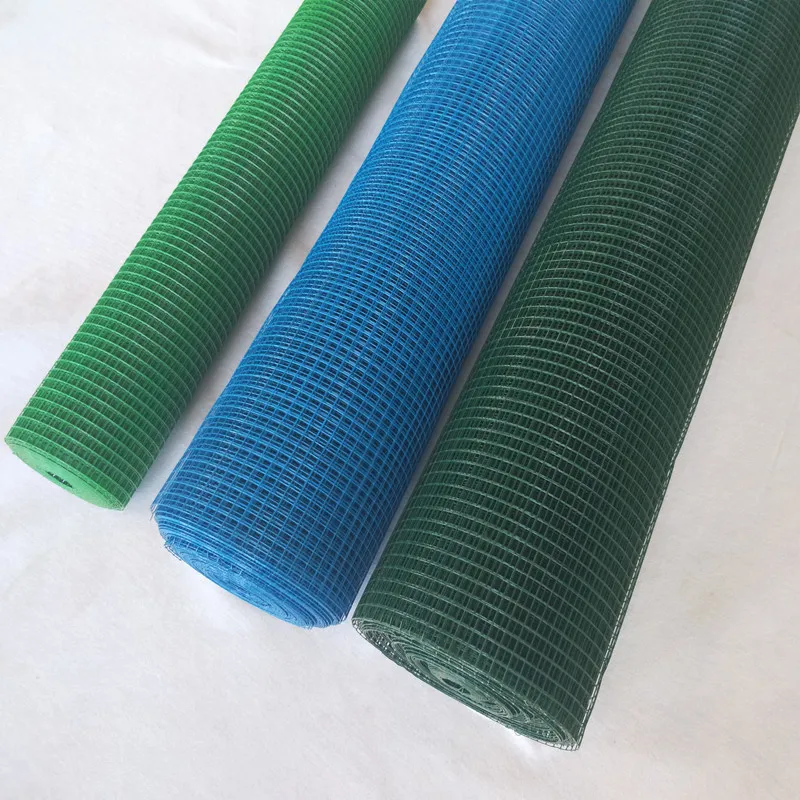

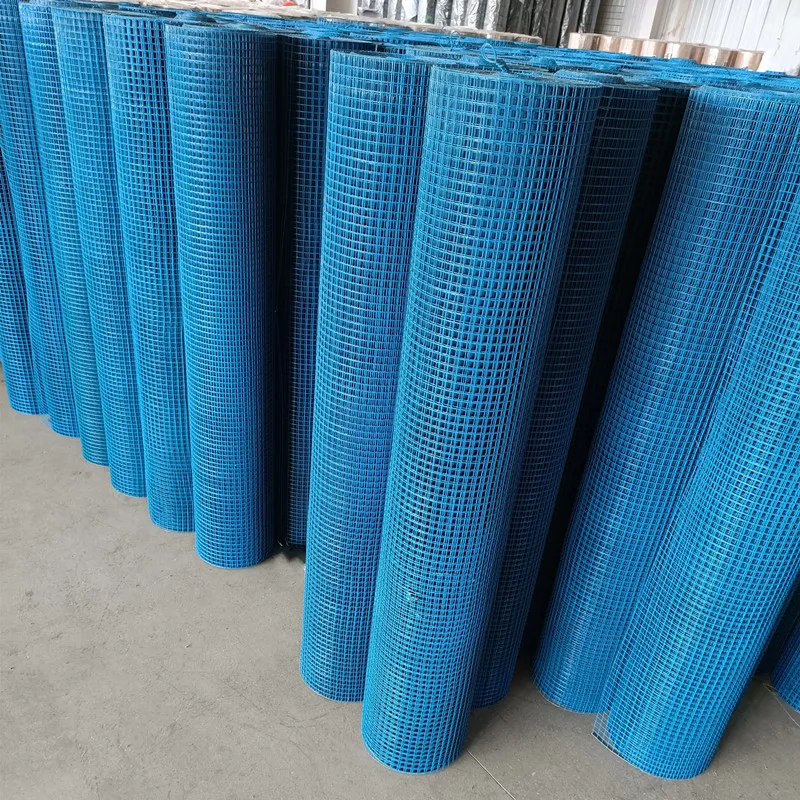

Standard roll dimensions are another critical specification, typically available in widths of 0.5m to 2.5m and lengths ranging from 15m to 30m, though custom dimensions are often available to meet specific project needs, especially for large-scale infrastructure projects or specialized industrial installations. The PVC coating thickness, usually between 0.4mm and 1.0mm, is crucial for assessing the product's corrosion resistance and lifespan. A thicker coating generally offers superior protection against harsh environmental elements, including saltwater, acidic rain, and industrial chemicals, making it ideal for coastal installations or chemical processing facilities. The PVC material itself is engineered for excellent UV resistance, preventing premature fading, cracking, and degradation under prolonged sun exposure, which is critical for outdoor applications. Furthermore, the selection of PVC color, ranging from standard green and black to custom hues, allows for integration with surrounding aesthetics or corporate branding, an important consideration for commercial and public sector projects. These parameters collectively determine the mesh's mechanical properties, environmental resistance, and overall cost-effectiveness, emphasizing the need for a detailed understanding of these specifications to select the most appropriate PVC Coated Welded Wire Mesh solution.

| Parameter | Common Range/Value | Impact on Performance |

|---|---|---|

| Core Wire Diameter (Gauge) | 0.8mm - 6.0mm (22-6 Gauge) | Determines strength, rigidity, and load-bearing capacity. Thicker wires for heavy-duty applications. |

| Mesh Opening (Aperture) | 6x6mm to 75x75mm (0.25" to 3") | Affects visibility, containment effectiveness, and suitability for specific uses (e.g., small animal barriers vs. security fencing). |

| PVC Coating Thickness | 0.4mm - 1.0mm | Directly impacts corrosion resistance, UV stability, and overall lifespan. Thicker coating offers superior protection. |

| Roll Width | 0.5m - 2.5m (approx. 1.6ft - 8.2ft) | Influences ease of installation and suitability for various fence heights or barrier dimensions. |

| Roll Length | 15m - 30m (approx. 50ft - 100ft) | Standard lengths for convenient transport and installation; custom lengths available for large projects. |

| Color Options | Dark Green, Black, Grey, White, Blue (custom available) | Aesthetic integration with surroundings, corporate branding, or specific safety requirements. |

| Tensile Strength (Mesh) | Typically 450-700 MPa | Measures resistance to breaking under tension; critical for security and structural applications. |

| Operating Temperature Range | -30°C to +70°C | Ensures performance in extreme weather conditions without cracking or becoming brittle. |

The distinctive blend of robust steel and resilient PVC coating endows PVC Coated Welded Wire Mesh with a suite of advantages that position it as a superior choice for a multitude of demanding applications across various industries. Foremost among these is its exceptional corrosion resistance. The thick, uniform PVC layer acts as an effective barrier, shielding the underlying steel from moisture, corrosive chemicals, saltwater, and atmospheric pollutants. This makes it an ideal material for coastal environments, industrial chemical processing plants, and water treatment facilities, where traditional metal fences would quickly degrade due to rust and oxidation. The enhanced resistance significantly extends the product's operational life, often reaching 15-20 years or more, drastically reducing the need for frequent replacements and associated labor costs, thereby contributing to substantial long-term savings for businesses.

Beyond corrosion protection, the PVC coating offers superior UV stability, preventing embrittlement, cracking, and color fading even under prolonged exposure to intense sunlight. This ensures the mesh maintains its structural integrity and aesthetic appeal over decades, a crucial factor for visible installations like public park fencing or commercial property boundaries. Its low maintenance profile is another significant benefit; unlike painted or uncoated metal, PVC Coated Welded Wire Mesh rarely requires repainting, scraping, or rust removal, needing only occasional cleaning. This translates into reduced operational expenses and less downtime for maintenance teams. Furthermore, the PVC coating provides a smoother, softer surface compared to raw wire, enhancing safety by minimizing sharp edges, which is particularly beneficial for animal enclosures, children's play areas, and public access points. The material also offers good impact resistance and sound dampening properties, contributing to overall durability and a quieter environment in some applications. These combined attributes make it a cost-effective, durable, and reliable solution, proving its value by delivering consistent performance and minimizing lifecycle costs across a wide array of B2B applications.

The versatility and superior performance characteristics of PVC Coated Welded Wire Mesh enable its widespread adoption across an impressive array of industrial, commercial, and public sector applications. Its primary use is undoubtedly in various forms of fencing, including perimeter security for industrial complexes, airports, and military installations, where its robust structure and anti-climb properties are critical. For commercial properties and residential estates, it provides a durable, aesthetically pleasing, and low-maintenance boundary solution. In agricultural settings, this mesh is extensively utilized for constructing secure animal enclosures, poultry cages, pet fencing, and horticultural support structures like trellises. Its resistance to animal waste and cleaning agents, combined with a smooth, non-toxic surface, ensures the well-being of livestock and pets, while preventing degradation over time. Beyond traditional fencing, it is a key component in gabion baskets for erosion control and retaining walls, especially in civil engineering projects near water bodies due to its exceptional corrosion resistance.

Furthermore, PVC Coated Welded Wire Mesh finds critical application in infrastructure development, such as roadside and railway barriers, where its durability against environmental elements and minimal visual obstruction are valued. In public utility sectors, including water supply and drainage systems, it is employed for protective screens, filtration components, and secure enclosures for equipment, offering long-term reliability in damp or chemically exposed environments. Specific examples include its use in wastewater treatment plants for screening coarse solids, or in pumping stations to prevent debris ingress, where its resistance to both water and various chemicals ensures operational continuity. Its adaptability extends to recreational facilities for sports field enclosures, park boundaries, and protective barriers. The ability to customize dimensions, mesh sizes, and colors allows for tailored solutions for complex projects, proving its indispensable value across sectors that demand both high performance and long-term cost-effectiveness. This broad spectrum of applications underscores its position as a go-to material for engineers, contractors, and project managers seeking dependable and enduring barrier and containment solutions.

Selecting the right manufacturer for PVC Coated Welded Wire Mesh is a critical decision that impacts product quality, project timelines, and overall cost-effectiveness. Key factors to consider include the manufacturer's adherence to international quality standards such as ISO 9001, their proven track record in the industry, and their capacity for customized solutions. A reputable manufacturer will demonstrate transparent production processes, rigorous quality control at every stage, and comprehensive testing protocols including salt spray tests for corrosion resistance and UV aging tests to ensure coating durability. Experience in serving specific industries like petrochemical, mining, or large-scale infrastructure projects is a strong indicator of their capability to meet specialized requirements. Furthermore, a comparison should extend beyond just price, focusing on the total value proposition, which includes material quality, coating consistency, weld strength, and the reliability of supply chains, especially for large-volume orders or projects with tight deadlines.

The ability to provide customized solutions is a significant advantage for B2B buyers. Project specifications often demand unique mesh configurations, specific wire gauges, non-standard roll dimensions, or bespoke PVC colors to align with architectural designs or corporate branding. A flexible manufacturer should be capable of producing PVC Coated Welded Wire Mesh with specific mesh openings (e.g., small apertures for rodent control or larger ones for aesthetic appeal), varying wire diameters to adjust strength, and precise coating thicknesses to meet environmental demands. They should also offer pre-cut panels or specific fabrication services, reducing on-site labor and material waste for clients. Furthermore, the provision of robust after-sales support, including technical assistance, warranty assurances, and efficient logistics, is crucial for fostering long-term partnerships. Engaging with manufacturers who can provide detailed technical data sheets, sample products, and case studies of successful projects offers invaluable insights into their capabilities and commitment to quality. Trust in a supplier is built upon consistent product excellence, reliable delivery, and proactive customer service, ensuring that your investment in PVC Coated Welded Wire Mesh yields optimal returns and sustained performance throughout its extensive lifespan.

Establishing trust and demonstrating authoritativeness are paramount in the B2B sector, particularly for technical products like PVC Coated Welded Wire Mesh. Reputable suppliers distinguish themselves through unwavering commitment to quality assurance, backed by verifiable certifications and transparent operational practices. Compliance with international standards such as ISO 9001 for quality management systems is non-negotiable, indicating a systematic approach to consistent product delivery. Beyond this, adherence to specific material standards like ASTM (American Society for Testing and Materials) ensures that the wire mesh meets defined specifications for tensile strength, weld integrity, and material composition. For the PVC coating, certifications related to UV stability (e.g., ASTM G154 for accelerated weathering), adhesion strength, and environmental safety (e.g., REACH or RoHS compliance) further validate product quality and safety. Manufacturers should readily provide test reports, often from third-party laboratories, confirming the performance characteristics such as salt spray resistance (e.g., exceeding 1000 hours without red rust) and impact resistance, which directly influence the product's longevity and reliability in demanding applications.

Our commitment to clients extends beyond product quality to encompass reliable delivery schedules, comprehensive warranty provisions, and responsive customer support. We understand that project timelines are critical for B2B operations, which is why we offer clear delivery estimates and work diligently to meet agreed-upon deadlines, even for large-scale orders or complex custom fabrications. Our PVC Coated Welded Wire Mesh products typically come with substantial warranty periods, often ranging from 5 to 10 years, covering material defects and coating performance, underscoring our confidence in product durability. In terms of customer support, a dedicated team of technical experts is available to assist with product selection, installation guidance, and troubleshooting, ensuring seamless project execution from initial consultation to post-installation support. We pride ourselves on cultivating long-term partnerships, reflected in positive client feedback and repeat business from diverse industries, including major infrastructure developers and agricultural conglomerates. Our extensive service history and a portfolio of successfully completed projects across various sectors serve as tangible proof of our experience and reliability, providing decision-makers with the confidence that they are partnering with a proven leader in PVC Coated Welded Wire Mesh solutions.

To further assist B2B professionals in their decision-making process regarding PVC Coated Welded Wire Mesh, we've compiled answers to some frequently asked questions. These insights aim to clarify common concerns and provide additional technical details.

A1: PVC Coated Welded Wire Mesh generally boasts a significantly longer lifespan than standard galvanized mesh, often lasting 15-20 years or more, depending on environmental conditions and coating thickness. The PVC layer provides an additional, superior barrier against corrosion, abrasion, and UV degradation, which are the primary factors leading to the deterioration of galvanized products. While galvanized mesh offers good initial protection, its zinc coating can be compromised by acidic rain, saltwater, or mechanical damage over time. The dual protection of galvanized wire beneath a robust PVC coating offers unparalleled durability, especially in harsh coastal, industrial, or agricultural environments where traditional materials would fail prematurely. This extended service life translates directly into lower lifecycle costs and reduced maintenance burdens for B2B clients.

A2: Absolutely. PVC Coated Welded Wire Mesh is exceptionally well-suited for marine and highly corrosive environments, which includes coastal areas, chemical plants, and wastewater treatment facilities. The polyvinyl chloride (PVC) coating is inherently resistant to salt spray, acids, alkalis, and many other corrosive agents, preventing the underlying steel wire from direct exposure. This makes it a preferred material for applications where long-term integrity in aggressive atmospheres is critical. For optimal performance in such extreme conditions, it is advisable to specify products with a thicker PVC coating (e.g., 0.8mm to 1.0mm) and ensure the core wire itself is hot-dip galvanized prior to PVC coating, offering a dual-layer defense against degradation. Our products undergo rigorous salt spray testing to validate their performance in these challenging conditions, exceeding industry standards for corrosion resistance.

A3: While PVC Coated Welded Wire Mesh can be cut on-site using appropriate tools like wire cutters or bolt cutters, it is important to note that cutting will expose the underlying steel wire at the cut points. This exposed area will no longer benefit from the PVC coating's protection and may become susceptible to corrosion over time if not properly treated. For long-term integrity, especially in critical applications or corrosive environments, it is highly recommended to seal any cut ends with a touch-up paint or a specialized PVC-compatible sealant. Ideally, for precision and to maximize product lifespan, clients should provide exact dimensions for pre-fabricated panels or rolls where possible, minimizing the need for on-site modifications and ensuring that all edges are properly protected during the manufacturing process. This proactive approach ensures maximum durability and adherence to project specifications.

A4: Lead times for large-volume orders of PVC Coated Welded Wire Mesh can vary depending on the specific product specifications, current production schedule, and order quantity. Typically, for standard specifications, lead times range from 3 to 6 weeks from order confirmation to dispatch. For highly customized products or exceptionally large quantities, lead times may extend to 8-12 weeks. We recommend early engagement and detailed discussion of project timelines to ensure that production and delivery align perfectly with your project schedule. Our advanced manufacturing capabilities and efficient logistics network enable us to manage substantial orders effectively, providing transparent communication throughout the process to keep clients informed of their order status. We also maintain a stock of popular specifications to facilitate quicker deliveries for urgent requirements, reinforcing our commitment to reliable supply chain management.

RELATED PRODUCTS