The global Reno Mattress market is witnessing robust growth driven by accelerated infrastructure upgrade, increasingly stringent environmental policies, and the rising emphasis on sustainable water management. According to ResearchAndMarkets, the sector is projected to register a CAGR of 7.8% through 2028, fueled by large-scale riverbank protection, hydraulic engineering, and flood control initiatives. Technological advancements like anti-corrosion Galfan-coated wire mesh, enhanced automation in CNC fabrication, and third-party ISO 9001:2015 compliance audits, are paving the way for higher durability and reliability in Reno Mattress deployments.

| Parameter | Typical Value | Standards/Notes |

|---|---|---|

| Material | Galfan-coated steel wire (Zinc-5%Al-MM alloy) or Heavy Zinc (≥245g/m²) | ASTM A975 / EN 10223-3 |

| Wire Diameter | 2.0 – 3.2 mm | Customizable |

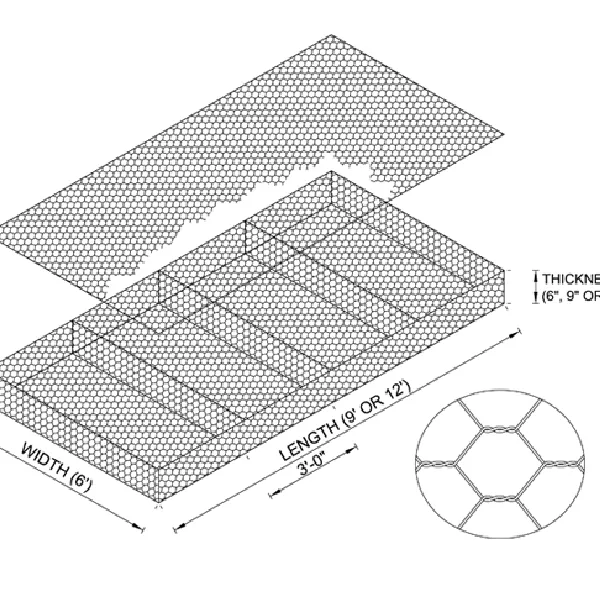

| Mesh Size | 60x80 mm / 80x100 mm | Hexagonal Double Twist |

| Mattress Thickness | 0.17 m, 0.23 m, 0.30 m | Standard Range |

| Length x Width | 2x1m, 3x2m, 6x2m etc. | Custom modules up to 40m² |

| Coating | Galfan, Hot-dipped Zinc, PVC, or PA6 Polyamide | ISO 12944-5, anti-corrosive |

| Service Life | ≥30 years (with Galfan/PVC) | Accelerated salt spray tested |

Process flow diagram of Reno Mattress production (See details)

Figure: Comparative service life across mainstream gabion and Reno Mattress systems. Source: Internal testing, ISO 9227 salt spray validation.

Photo: Typical Reno Mattress application in hydraulic slope reinforcement project

Pie chart: Major market distribution for Reno Mattress application (Source: Tikemetal Market Reports)

| Brand | Core Wire Material | Mesh Structure | Certification | Custom Service | Typical Service Life |

|---|---|---|---|---|---|

| Tikemetal | Zn-5%Al alloy, low carbon <0.08%, ASTM | CNC double twist | ISO 9001, ASTM A975 | Full bespoke sizing/coating | 30–38 years |

| Maccaferri | Galfan, Carbon Steel | Double twist | UNI EN ISO 9001 | Limited | 25–33 years |

| Welded Mesh Co. | Hot-dipped galvanized | Welded mesh | ISO 9001 | Standard only | 12–16 years |

Comparison based on public disclosures and third-party test reports between major Reno Mattress manufacturers (2024).

Photo: Custom-fabricated Reno Mattress modules for irregular irrigation canal reconstruction (client: Inner Mongolia Water Authority, 2023)

Over 42,000m² of Reno Mattress modules were installed along the flood-battered riparian slopes. After two spring flood events, SCADA monitoring confirmed slump reduction by 96%, zero mesh rupture, and ongoing native plant recovery.

Custom Galfan+PA6 coated mattresses enabled the refurbishment of oil-laden discharge channels. After 18 months in brackish + oil-saturated conditions, test coupons showed corrosion mass loss under 3% (ISO 9227), with high-impact rocks causing no mesh pull-out.

Modules with integrated inspection ports reduced in-situ cane field irrigation leaks by over 84%, with verified outflow rates aligning to US EPA Robustness Class II criteria (EPA Water Research).

Selected End Users: Sinohydro Corp., Bechtel Ltd, Saudi Ministry of Water, EDF Hydro, Oman National Irrigation, Brazilian State Agronomy Boards.

Mesh strength retention comparison after accelerated salt spray (ISO 9227:2017). Data from Tikemetal R&D Lab, 2024.

RELATED PRODUCTS