Black Iron Wire: Market Trends, Technical Insights & Custom Solutions

Complete Guide to

Black Iron Wire (

black iron wire), Black Annealed Iron Wire, Supplier Landscape, Industrial Applications, and Performance Data

1. Industry Trends & Market Overview

The

black iron wire market is projected to expand at a CAGR of 4.1% (2023–2028, MarketQuest Research), driven by:

- Expanded demand in construction, petrochemical, agricultural, and utility sectors;

- Technological innovations in annealing, surface treatment, and corrosion protection;

- Growing preference for custom wire specifications and high-performance alloys.

[Source: Global Black Iron Wire Market Research 2024, MarketQuest]

Black annealed iron wire is especially critical for internal reinforcement, baling, and mesh production, attributed to its flexibility, tensile strength, and cost-effectiveness. Sourcing from a reliable iron wire supplier ensures consistency, compliance, and competitive black annealed iron wire quotes in bulk procurement.

2. Black Iron Wire: Comprehensive Parameter Comparison

| Property |

Black Iron Wire |

Black Annealed Iron Wire |

Galvanized Wire (for comparison) |

| Material Standard |

Low Carbon Steel (Q195, Q235) |

Low Carbon Steel |

Low/Medium Carbon Steel + Zinc Coating |

| Wire Diameter (mm) |

0.2 – 6.0 |

0.15 – 5.5 |

0.2 – 5.0 |

| Tensile Strength (N/mm²) |

350 – 550 |

300 – 450 |

450 – 800 |

| Elongation (%) |

10 – 25 |

12 – 30 |

5 – 15 |

| Coating/Finish |

None (Black Oxide Film) |

Black (Annealed) |

Galvanized (Zn) |

| Industry Compliance |

ISO 9001, ASTM A510 |

ISO 9001, AISI |

ISO 9001, ASTM A641 |

| Corrosion Resistance |

Medium (improved after annealing) |

Medium–High |

High |

| Common Uses |

Tying, Baling, Reinforcement, Mesh Making |

Wire Mesh, Binding, Construction |

Fencing, Outdoor, Marine |

All values are typical ranges; actual values may vary by supplier/specification. Refer to

ASTM A510 for black iron wire standards.

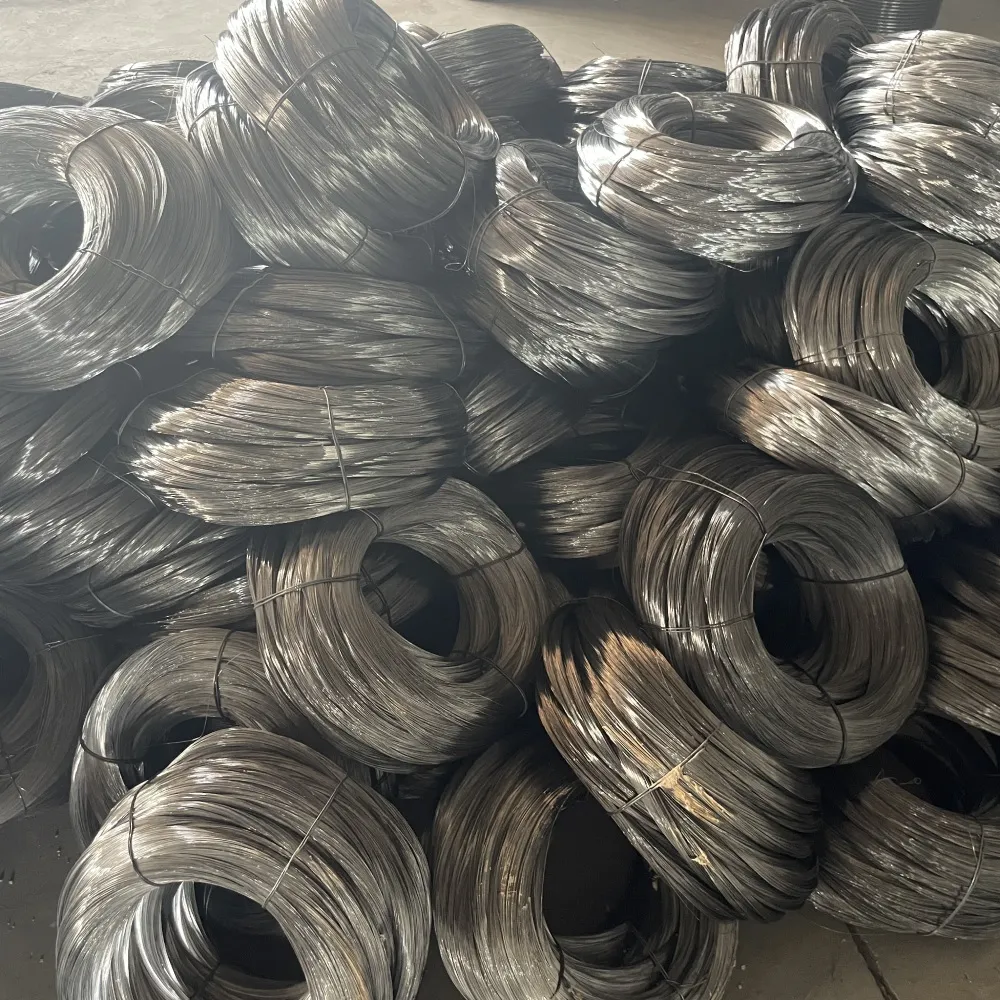

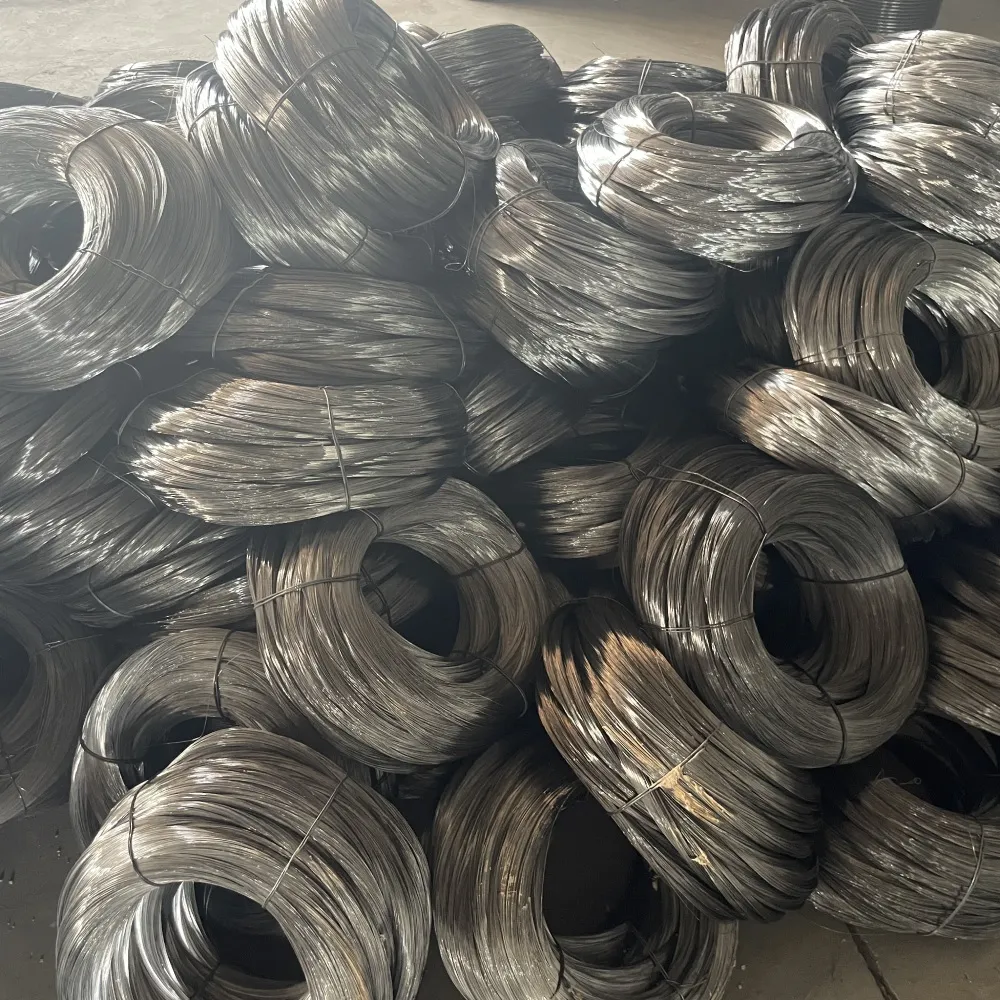

3. Black Iron Wire Manufacturing Process (with Visual Flow)

Black iron wire is produced through a meticulous series of metallurgical processes, ensuring optimal mechanical performance and surface quality.

- Wire Rod Selection

High-grade low-carbon steel (Q195/Q235) with certified chemical composition, accredited by ISO and AISI.

- Drawing

Progressive cold drawing reduces rod diameter; achieves uniformity & optimal mechanical strength.

- Annealing (Key Step)

Wire heated in oxygen-lean furnace (~700℃) and cooled, increasing ductility and surface oxidation, forming a black oxide film – key for flexibility.

- Surface Treatment

Optional light oiling or phosphate passivation to enhance storage life.

- Spooling/Coiling

Wires are wound into coils or cut into straight wire for shipping and secondary processing.

- Inspection & Quality Control

Rigorous testing (tensile, elongation, surface) in accordance with ISO 9001 and ANSI/ASTM standards before packing.

Process flow: Wire Rod → Drawing → Annealing (Key) → Surface Treatment → Coiling → Inspection.

4. Technical Parameter Trends (Data Visualization)

Tensile strength, elongation, and diameter trends drawn from leading iron wire supplier data (global average, 2018–2023).

5. Black Wire Technical Specifications: Specifications & Competitive Comparison

Product Name: Black Wire

URL: https://www.tikemetal.com/black-wire.html

Certifications: ISO 9001, SGS Test Report, CE marking

| Parameter |

Black Wire (Tikemetal) |

Standard Iron Wire |

Market Average |

| Material |

Q195/Q235 Low Carbon Steel |

Q195 |

Q195/Q215 Mixed |

| Wire Gauge (BWG) |

8 – 22 |

8 – 18 |

10 – 20 |

| Wire Diameter (mm) |

0.2 – 6.0 |

0.3 – 5.0 |

0.4 – 5.5 |

| Tensile Strength (N/mm²) |

350 – 550 |

320 – 480 |

300 – 510 |

| Elongation (%) |

10 – 25 |

8 – 16 |

10 – 20 |

| Coil Weight (kg) |

25, 50, 100, Custom |

50, 100 |

50, 75 |

| Annealing |

Full Annealed/Soft |

Semi Annealed |

Semi Annealed |

| Surface |

Black Oxide, No Flaking |

Oxide, Some Flaking |

Black/Oxide Film |

Black Wire offers superior elongation and consistent mechanical performance, ideal for high-demand industrial applications.

Black Wire offers superior elongation and consistent mechanical performance, ideal for high-demand industrial applications.

6. Application Scenarios: Why Leading Factories Choose Black Iron Wire

-

Construction: Used for binding rebar, scaffolding, mesh/chicken wire, and as tie wire for concrete formwork.

-

Petrochemical: Employed for cable management, pipe hanger fabrication, earthing wires, and equipment fixing—its non-galvanized nature prevents chemical contamination.

-

Water Supply & Drainage: Applied in mesh basket manufacturing and fixing of pipeline insulation covers.

-

Metallurgy: Utilized in baling, furnace binding, and metal basket reinforcement projects, where elevated thermal endurability is needed.

-

General Industry: Core in packaging, fencing, handicrafts, and agricultural hoop/trellis systems.

Case Study:

Shanghai Metro Construction (2023) – Over 1,200 tons of

black iron wire supplied by Tikemetal used in station mesh reinforcement; key benefits cited:

- 15% time reduction in installation due to enhanced ductility;

- Low surface friction simplified handling and securing of mesh panels;

- Material accredited to ISO 9001 quality standard.

Testimonial: "Tikemetal's black annealed iron wire outperformed local market wires in workability, toughness, and finish consistency.”

- Project Procurement Manager, SMG

7. Supplier Comparison & Customization Solutions

Choosing the right

iron wire supplier is critical for project consistency, cost control, and regulatory compliance. Tikemetal delivers:

- 100% traceable raw materials & full in-house annealing lines

- Customizable coil weights, diameters, and finishes; min. MOQ = 1 ton

- Lead time: 7–15 working days for standard specs, express for urgent orders

- Global logistics, DDP/DDU available

Data source: General Administration of Customs PRC, 2023

Main Industry Partners:

- China Railway

- SINOPEC

- Emilsted Construction

- Warburg Pipe

- Jinshan Petrochemical

- Gucheng Engineering

Years of Service: 13+ years specialized black iron wire manufacturing

8. Get Your Black Annealed Iron Wire Quotes

Quotation Process: Email your wire gauge, surface, coil weight, quantity, port, and any required certificates.

Standard delivery: 7–15 days (in-stock), 18–25 days (custom specs)

Warranty: 12 months; factory certificate, mill test report, and SGS inspection available upon request.

Contact: sales@tikemetal.com | WhatsApp: +86-13572487190

9. Black Iron Wire: Expert FAQ

Q1: What is the material grade of black iron wire, and why is Q195/Q235 preferred?

A1: Black iron wire typically uses low-carbon steel grades Q195 or Q235, which provide a balance of tensile strength (350–550 N/mm²) and ductility, ensuring both flexibility and robustness for diverse usage.

Q2: What industry standards govern black iron wire production?

A2: Industry standards include ASTM A510 (General Requirements for Wire Rods), ISO 9001 (Quality Management), and ANSI specifications, guaranteeing mechanical and dimensional consistency.

Q3: How does black annealed iron wire differ from galvanized or plain iron wire?

A3: Black annealed wire is fully softened by thermal annealing, offering higher elongation and flexibility. Galvanized wire is zinc-coated for extreme anti-corrosion uses; annealed wire is more ductile, suited for tying/binding.

Q4: What about wire diameter tolerances and surface finish?

A4: Standard tolerance is ±0.05mm. Advanced surface treatment (oil/coating) resists rust and flaking; Tikemetal ensures a uniform black oxide film via controlled annealing.

Q5: What coil sizes and packaging are available?

A5: Standard coils are 25kg, 50kg, 100kg, and customizable. Each coil is shrink-wrapped, palletized, or as spooled straight-cut wire according to customer needs.

Q6: What is the installation standard for construction use?

A6: Installation practices adhere to GB50010 (China), ACI 318 (USA), and EN 1992 (Europe) for rebar tying/binding, ensuring structural integrity and safety.

Q7: How is product traceability and quality control ensured?

A7: Each black iron wire is batch-coded, along with mill test reports and certificates traceable to raw materials; third-party SGS/BV inspection available.

10. Trust, Certifications & Customer Support

- Product supplied to over 38 countries since 2011

- ISO 9001 certified; full conformity to ASTM, ANSI, and regional regulatory schemes

- Cooperation with key state infrastructure and petrochemical clients

- Rapid online support: support@tikemetal.com | 24/7 hotline available

- Documentation package: COA (Certificate of Analysis), Mill Test Report, and warranty attached to every shipment

Guarantee: If material fails to meet certified mechanical or chemical parameters, full product refund or replacement is provided.

11. References & Further Reading

-

"Mechanical & Durability Properties of Annealed Iron Wire in Construction Applications", International Journal of Materials Science (2022), Read Full Article.

-

“Black Iron Wire: Current Export Trends & Technology”, Wire & Cable Forum Forum Post.

-

“Quality Control in Iron Wire Production”, Metallurgical Industry Review (2023), Industry Article.

-

"ISO 9001:2015 – Quality management systems", Official ISO Standard.

-

"ASTM A510/A510M-22 – Standard Specification for Wire Rods", ASTM Official.

-

“Wire Annealing Technology & Impact on Mechanical Properties”, Steel Technologist Forum, Read More.

For product details and the latest

black annealed iron wire quotes, visit the

black iron wire page or contact our technical support team.

Black Wire offers superior elongation and consistent mechanical performance, ideal for high-demand industrial applications.

Black Wire offers superior elongation and consistent mechanical performance, ideal for high-demand industrial applications.