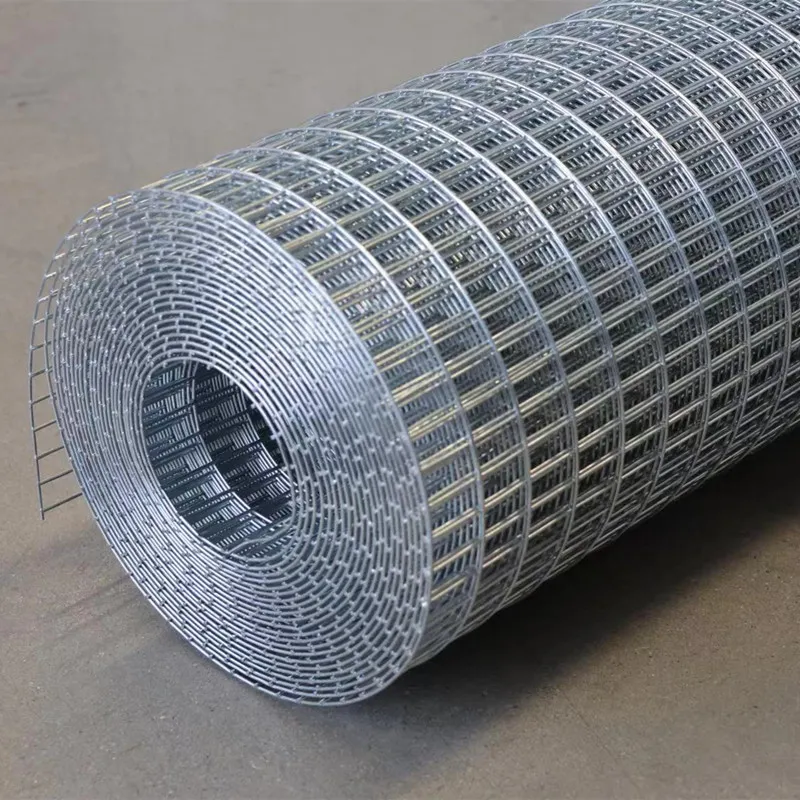

Hot Dipped Galvanized Welded Wire Mesh has emerged as a cornerstone material in modern construction, industrial protection, energy, and urban infrastructure due to its superior corrosion resistance and robust mechanical properties. The rising emphasis on long-lasting, maintenance-free solutions positions hot dipped galvanized meshes as a prime choice, meeting international standards and diverse customization demands. This comprehensive guide explores its market landscape, technical dimensions, application advantages, and competitive strategies, underscored with real-world data, visualizations, and professional insight.

1. Industry Trends & Market Overview

According to

ResearchAndMarkets, the global welded wire mesh market is projected to reach $7.4 billion by 2028, with

Hot Dipped Galvanized Welded Wire Mesh accounting for over 39% share due to its unparalleled durability. The growth is fueled by:

- Increasing investments in infrastructure, energy, municipal water, and transport projects.

- Stringent international standards for anti-corrosion (e.g., ISO 1461, ASTM A123).

- Expanding applications in petroleum, metallurgy, construction, horticulture, and animal husbandry.

- Demand for sustainable, eco-friendly, and recyclable solutions in public works.

Global Welded Wire Mesh Market Share (2023, by Type)

Hot Dipped Galvanized Welded Wire Mesh is manufactured by joining steel wires via automated welding and coating them with a zinc layer through hot-dip galvanization. This process, in strict accordance with

ISO 1461 and

ASTM A123 standards, delivers longevity and corrosion resistance ideal for harsh environments.

| Parameter |

Data/Range |

Industry Standard |

Typical Application |

| Material |

Low-carbon Steel (Q195, Q235), High-Strength Steel |

GB/T 343/ISO 16120 |

General Construction, Industrial |

| Wire Diameter |

0.5mm ~ 5.0mm |

Customized |

Heavy-duty fencing, cages, partition |

| Mesh Opening |

6.4×6.4mm to 100×100mm (1/4" to 4") |

ANSI/BSI |

Screening, Architectural Mesh |

| Galvanized Coating |

≥ 40-275 g/m² |

ISO 1461, ASTM A123 |

Outdoor/Marine/Industrial |

| Tensile Strength |

350-700 MPa |

GB/T 343 |

High-Security Installations |

| Panel Size |

Standard: 1m × 2m, 2m × 2.4m, Custom sizes |

ISO 2768 |

Perimeter, Barriers |

| Longevity |

15-30 Years (Depending on exposure & coating thickness) |

ISO 9227 (Salt Spray Test) |

Critical Infrastructure |

2.1. Manufacturing Flowchart

🔩

Raw Material

Selection

(GB/T 343 Steel Rods)

➡️

⚡

Wire Drawing

(Precision sizing)

➡️

🤝

Automatic Welding

(Electric Resistance)

➡️

🌊

Acid Pickling

& Surface Clean

➡️

🛡️

Hot Dip Galvanizing

(ISO 1461/ASTM A123)

➡️

🔬

QC Inspection

(Thickness, Bond, Salt Spray)

➡️

📦

Cutting, Packing

Shipping

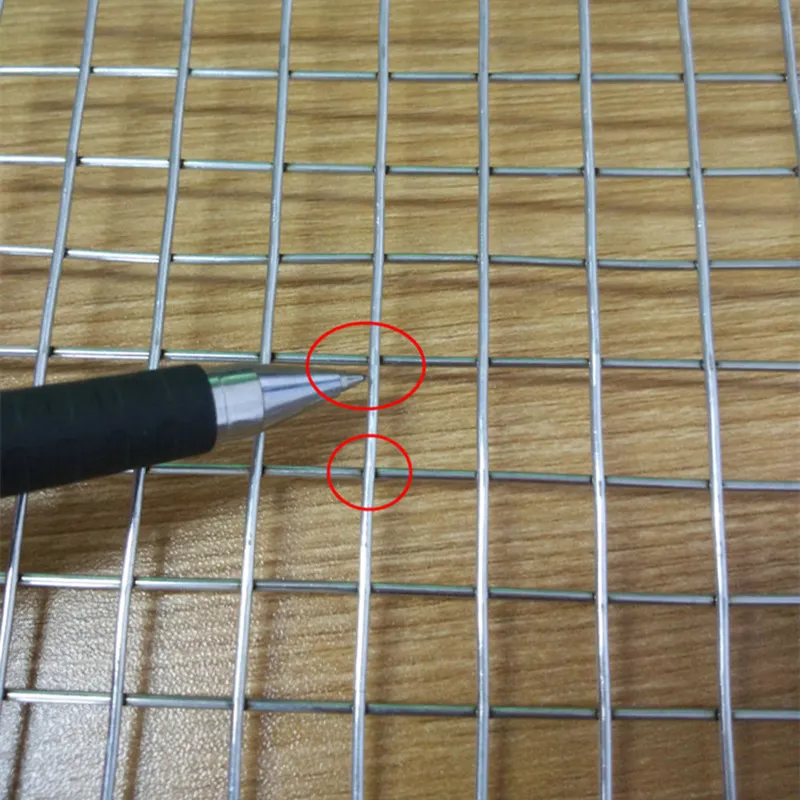

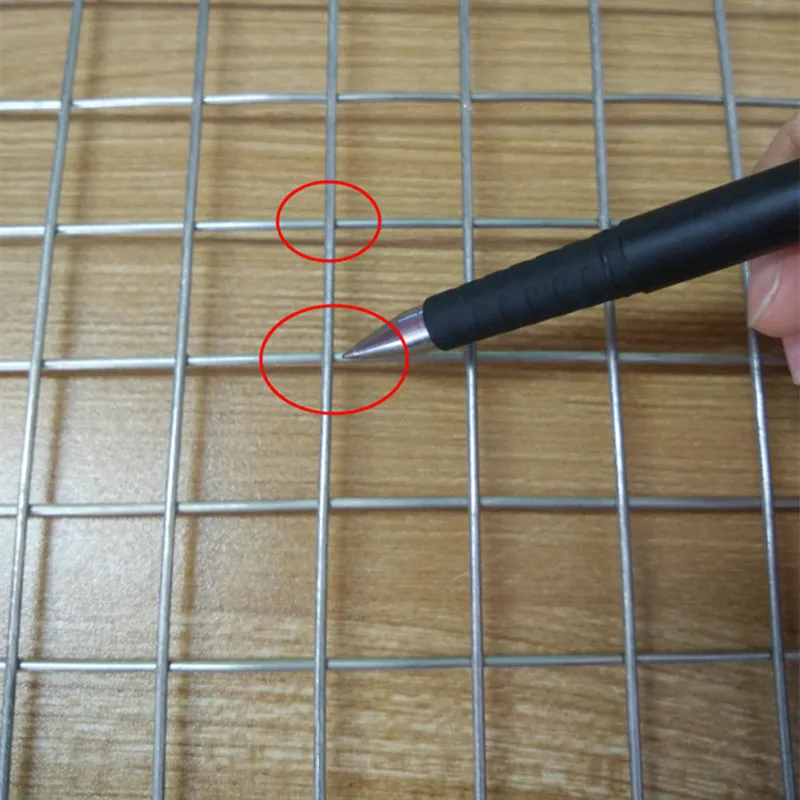

Each production step is governed by rigorous quality protocols:

- Steel rod traceability (Heat No.), surface purity analysis

- Welding strength per ISO 15614-1

- Coating thickness - minimum 40μm (test per ISO 2178)

- 48/96/240 Hour Salt Spray Test (ISO 9227)

- Dimensional and appearance inspection (ISO 2768)

1. Outstanding Corrosion Resistance — The hot dip process produces a metallurgical bond between zinc and steel, creating a barrier with self-healing abilities that protect even when cut or scratched.

2. Extended Lifespan: 15-30+ years service in most outdoor, marine, or industrial surroundings (ref:

Galvanizers Association - ISO 1461 FAQ)

3. Superior Mechanical Bond: Joints are welded, not twisted — giving excellent impact/tear resistance for perimeter, cages, security fencing.

4. Customizability: Wide range of aperture size, wire diameter, panel sizes, can be prefabricated or rolled.

- Environmental Safety: Zinc used is recyclable; meshes are sustainable and non-toxic (meets EU RoHS directives).

- High Weld Shear Strength: Resistance-welded mesh meets industrial loading/impact requirements.

- Low Maintenance: Total cost of ownership is up to 64% less than that of regular painted or electro-galvanized mesh (Research: Construction Industry Institute, 2022).

- Certification/Compliance: Many suppliers (incl. tikemetal.com) are ISO 9001, ISO 14001, and CE certified.

See Company Certification

3.1. Typical Application Scenarios

Hot Dipped Galvanized Welded Wire Mesh is integral to:

- Petrochemical facilities (e.g., security partitions, cable trays, refinery walkways).

- Metallurgy plants (blast proof fencing, machine guards).

- Municipal water and wastewater management (filtration, reinforcement of concrete structures).

- Transport infrastructure (roads, airports, tunnels – impact barriers and sound barriers).

- Construction (brick reinforcement, concrete slab support, wall mesh).

- Animal husbandry (cages, aviaries, livestock pens).

- Horticulture/landscape (boundary fencing, plant support).

4. Manufacturer Competitive Analysis

| Factor |

Tike Metal |

Other Manufacturers |

| Industry Certification |

ISO 9001, ISO 14001, CE, SGS |

ISO 9001 / None |

| Wire Grade Options |

Q195, Q235, A106, High Carbon |

Mainly Q195 |

| Galvanized Coating Thickness |

40 - 275 g/m² |

30 - 100 g/m² |

| Mesh Size Customization |

Full Custom (6.4-100mm) |

Limited (13mm, 25mm, 50mm) |

| Warranty |

>10 Years |

5-7 Years |

| Lead Time |

As fast as 7-12 days (bulk) |

18-30 days |

| Third-Party Audit |

SGS, TUV, BV Welcome |

Upon request |

| Major Export Market |

US, EU, MENA, AU |

Asia-Pacific Dominated |

| Customer Support |

24h×7 specialist engineer service |

Business time support |

5. Customized Solutions & Project Cases

5.1. Customization Capabilities (from tikemetal.com)

- Wire Diameter: 0.5-5.0mm, precision ±0.02mm, special alloys available

- Mesh Openings: Square/Rectangular (6.4mm up to 100mm); rolled or framed panels

- Panel Size: Standard 2m x 2.4m, custom up to 3m x 6m

- Surface Finish: Hot dip galvanized both after and before welding, double coating for marine applications

- Logistics: Export-grade steel pallets, custom branding, flexible shipping from China main ports

5.2. Case Study: Wastewater Treatment Plant, Australia (2023)

Challenge: Old concrete tanks at a municipal plant suffered severe mesh corrosion, with failures every 2-3 years.

Solution: Replaced with

Hot Dipped Galvanized Welded Wire Mesh, 3.5mm, 50×50mm, ISO 1461, double-zinc

Result: After 20,000+ hours of wet-dry cycling, no red rust; reduced maintenance by 60%, cost savings of $18,000+ per year.

Quote: “Galvanized panels from Tike Metal performed beyond spec; ideal for our harsh process water exposure.” –

Plant Chief Engineer, Melbourne

5.3. Case Study: Oil & Gas Perimeter Security, North Africa (2022)

Challenge: Security fencing subject to sand, wind, saline humidity.

Solution: 2.8mm × 5.0mm custom panels, thickest zinc layer available, anti-cut, tamper-proof specs.

Impact: Over 12km of fencing erected with zero corrosion claims in 3 years, passing ISO 9227 1,500-hr test; certified by EPC contractor.

6. Product Performance Data Analysis

Longevity Comparison: HDG vs Electro-Galvanized vs Painted Wire Mesh

7. FAQ: Professional Terminology & User Concerns

Q1: What does "Hot Dipped Galvanized" mean for welded wire mesh?

Answer: It refers to the process of immersing welded mesh in molten zinc (~450°C), ensuring each surface, corner, and joint is completely sealed by a thick, robust zinc-iron alloy layer, yielding maximum weather and corrosion resistance. Unlike electro-plating, this method leaves no bare areas at welds.

Q2: What wire materials are commonly used?

Answer: Typically, low carbon steel grades (such as Q195, Q235 per GB/T 343 or ASTM A36), with options for higher-tensile or stainless steel for critical/security usages.

Q3: What are mesh opening and wire diameter, and why are they important?

Answer: Mesh opening refers to the clear space between wires (e.g., 25mm × 25mm); wire diameter (e.g., 2.5mm) affects strength, weight, and flexibility. These determine suitability for intended loads and particle filtration sizes.

Q4: What international standards apply to HDG welded mesh?

Answer: Key standards include ISO 1461 for hot-dip coating, ISO 15614-1 for welding qualification, and ASTM A123 for material and coating quality.

Q5: How is the corrosion resistance of HDG mesh tested?

Answer: Salt-spray (fog) corrosion tests (ISO 9227), adhesion, thickness (ISO 2178), and impact/peel adhesion checks are standard for qualifying every batch.

Q6: Is installation of HDG welded mesh different from other meshes?

Answer: While physical fixing is similar (panels/rolls attached with clips, ties, or brackets), additional grounding, edge sealing, or HDG-compatible hardware is recommended for full system longevity.

Q7: What is the warranty and after-sales service for projects?

Answer: Leading suppliers offer 10-year+ anti-corrosion warranty, free technical guidance, and fast inspection support (see

Tike Metal's service policy).

8. Delivery Cycle, Quality Assurance & Support

Delivery: Standard products typically ship within 7–12 business days. Large/custom orders: 18–25 days based on volume.

Quality Assurance: 100% inspection protocol, mill certificates, third-party (SGS, BV, TUV) inspection welcome.

Warranty: 10–30 years anti-corrosion warranty (application-dependent).

Customer Support: Project design & customization advice, site-specific engineering, video QA, installation manuals, 24/7 technical hotline.

Contact directly via product page for tailored solutions or after-sales queries.

9. Reference & Further Reading