PVC Coated Welded Wire Mesh is a key solution in the Manufacturing industry, specifically within Metal Products Manufacturing and Wire and Mesh Products Manufacturing. This article explores how SHENZHOU TIKE METAL CO., LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

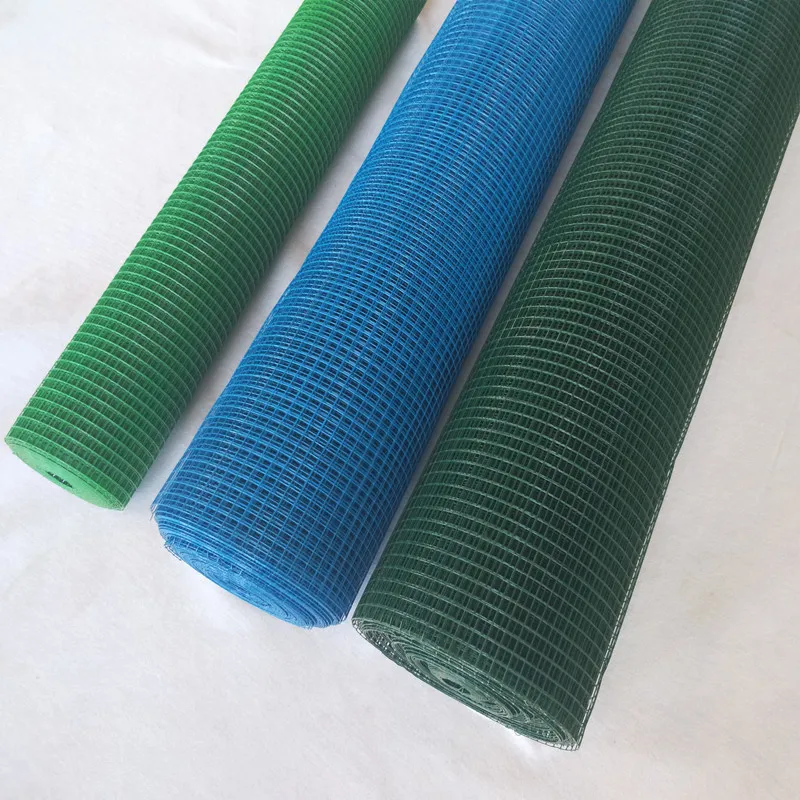

PVC coated welded wire mesh combines a low-carbon steel or galvanized steel core with a durable polyvinyl chloride coating. The process creates a mesh panel or roll with strong electrical-resistance welds at each intersection, then the mesh is encapsulated with a uniform PVC layer. For B2B buyers in Manufacturing—especially Metal Products Manufacturing and Wire and Mesh Products Manufacturing—this construction delivers corrosion resistance, color stability, and safer handling compared with bare metal alternatives. The result is a long-lasting, visually consistent material that’s easy to fabricate, install, and maintain across diverse industrial environments.

From factory partitions and machine guards to perimeter fencing, racks, cages, and agricultural enclosures, PVC coated welded wire mesh provides a robust, attractive, and low-maintenance solution. Fabricators value its smooth surface for safer handling, while integrators appreciate repeatable panel flatness, which supports faster assembly and better fit-up. The PVC jacket helps resist moisture, salt, fertilizers, and chemicals, making it suitable for coastal installations, livestock operations, and high-traffic industrial sites where durability and appearance matter.

Total cost of ownership hinges on service life, downtime, and maintenance. PVC coated welded wire mesh typically extends usable life versus plain or lightly galvanized mesh by providing a barrier against abrasion and corrosion. This reduces repainting, touch-up, and premature replacement costs—particularly in humid, coastal, or chemical-exposed environments. Installation is straightforward; mesh can be cut, bent, and framed using standard tools, with fewer sharp burrs and less surface prep required before use.

Sustainability initiatives and evolving regulations are influencing material selection across the wire and mesh sector. Steel’s recyclability and longer-lasting protective systems support lower embodied impacts over a product’s life. PVC coated welded wire mesh helps extend replacement cycles, which in turn reduces waste and transport emissions. Buyers increasingly seek RoHS- and REACH-conscious solutions, low-VOC processes, and responsible packaging aligned with corporate ESG targets. Demand is rising in infrastructure, utilities, agriculture, and logistics—especially where corrosion resistance and color coding advance safety and compliance.

PVC coated welded wire mesh provides a dependable balance of strength, corrosion resistance, and visual appeal for Manufacturing, Metal Products Manufacturing, and Wire and Mesh Products Manufacturing. With versatile formats, consistent weld integrity, and a protective PVC layer, it supports safe, efficient fabrication and long-term performance in demanding environments. SHENZHOU TIKE METAL CO., LTD. delivers reliable quality and customization, helping B2B buyers optimize cost, durability, and brand presentation across projects and product lines.

RELATED PRODUCTS