Decorative Perforated Metal Sheets is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal products for construction. This article explores how SHENZHOU TIKE METAL CO., LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

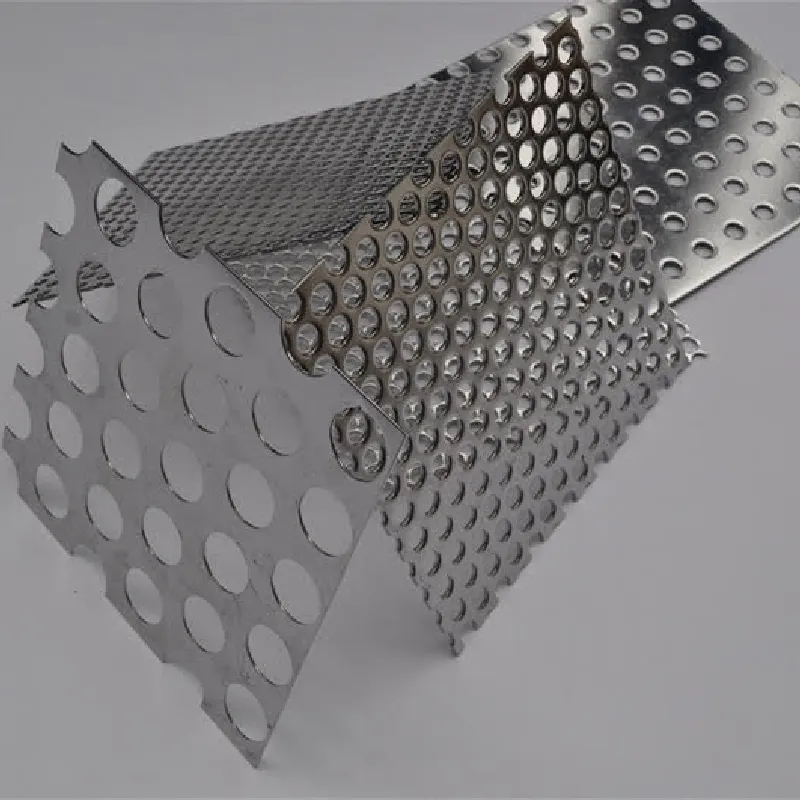

Decorative Perforated Metal Sheets combine structural strength with design flexibility, making them indispensable across modern building envelopes, interiors, and infrastructure. Produced by precision punching or laser perforation, these sheets are available in round, square, slotted, and hex patterns—including high-visibility hex perforated metal—for tailored airflow, light transmission, and aesthetics. Typical materials include aluminum, galvanized steel, and stainless steel (such as 304/316), with common thicknesses from 0.5–3.0 mm and open-area ratios from 10–60% depending on hole size and pitch. Finishes like powder coating, anodizing, or brushing support both durability and brand-driven design goals.

For construction-focused manufacturers, Decorative Perforated Metal Sheets bring a unique blend of performance and design. They’re frequently used for façade cladding, architectural screens, stair and balcony infill panels, machine guards, equipment enclosures, ceiling baffles, column wraps, sunshades, and wayfinding/signage. Compared with solid sheet, perforation reduces weight, enhances ventilation, and improves acoustic behavior (when paired with absorptive backing), all while maintaining structural integrity and visual consistency across large runs.

Total cost of ownership improves when lightweight panels reduce structural demands and installation time. Decorative Perforated Metal Sheets are durable, corrosion-resistant (with appropriate material/finish), and straightforward to maintain—typically requiring only periodic cleaning with mild detergents. Their long service life and modularity lower replacement and lifecycle costs while protecting aesthetics in high-traffic or harsh environments. For OEMs and contractors, consistent hole geometry and flatness reduce field rework and speed installation, supporting predictable schedules and ROI.

The construction market is prioritizing circularity, responsible sourcing, and design for disassembly. Decorative Perforated Metal Sheets align with these goals: metals are highly recyclable, perforation reduces overall material mass, and open-area strategies support passive ventilation and daylighting approaches. Powder coating technologies with low-VOC formulations and long-lasting finishes further support environmental objectives and reduce maintenance impacts across the lifecycle. Architects and OEMs are also adopting parametric design to customize hole geometries, including hex perforated metal, enabling performance tuning without sacrificing manufacturability.

Decorative Perforated Metal Sheets deliver structural reliability, design versatility, and lifecycle value for manufacturers in the fabricated metal products and construction sectors. With options ranging from classic round patterns to engineered hex and custom perforations, they help teams meet airflow, safety, and branding goals in one system. SHENZHOU TIKE METAL CO., LTD. provides dependable manufacturing, consistent finishes, and responsive engineering support to keep projects on spec and on schedule.

RELATED PRODUCTS