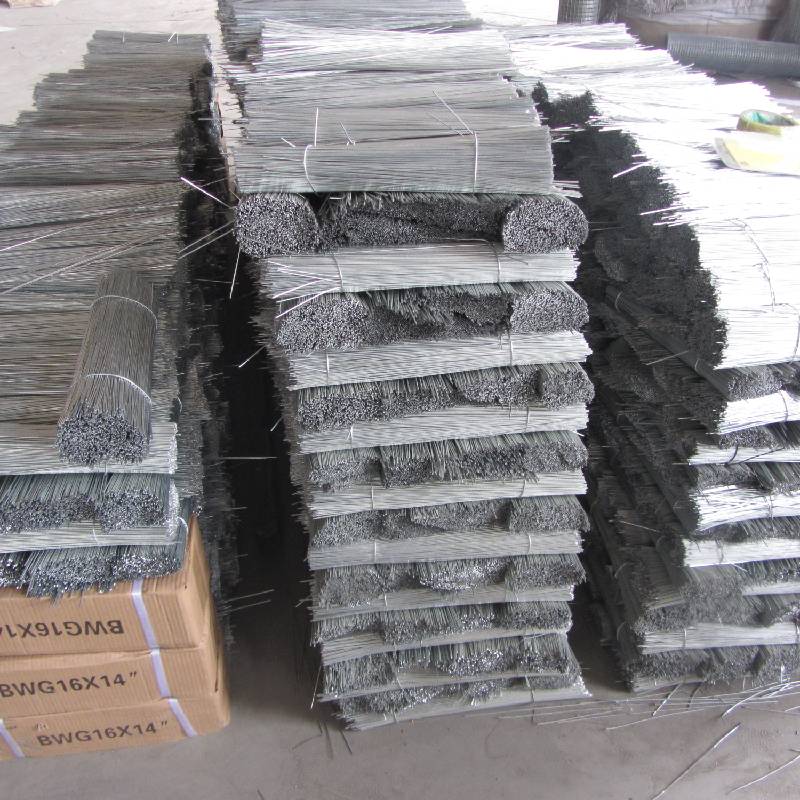

If you work with insulation, packaging lines, or light fabrication, you’ve probably handled Cutting Wire at some point. To be honest, it’s the quiet hero on job sites: small, strong, and—surprisingly—where downtime often starts if quality slips. I recently toured a plant on the east side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui, Hebei, and walked away with a simple note in my pocket: “good wire saves hours.”

Across factories and construction sites, buyers want Cutting Wire that’s traceable, coil-stable (no bird’s nests), and certified. Real-world demand is shifting to stainless 304/316 for food/cleanroom zones and zinc-coated high-carbon for outdoor crews. Shorter lead times matter too—many customers say they’ll pay a hair more for consistent diameter and straightness.

Below are representative specs from recent batches—actual performance can vary a little with environment and handling (that’s life on-site):

| Material Grade | Diameter (mm) | Tensile Strength (MPa) | Coating/Finish | Tolerance | Typical Use |

|---|---|---|---|---|---|

| High-carbon (≈82B) | 0.30–1.80 | 1800–3100 | Plain / Zinc | ±0.01–0.03 mm | Site cutting, straps, fixtures |

| Stainless 304/316 | 0.25–1.20 | 600–1500 | Bright drawn | ±0.01 mm | Food, cleanroom, corrosion risk |

| Tungsten alloy | 0.10–0.30 | Very high | Bare | ±0.005 mm | Precision slicing, lab rigs |

Materials are sourced, drawn in multi-pass dies, heat treated, then surface-finished (bright or zinc) and spooled. QA checks include:

Service life: indoors ≈ 12–24 months; outdoors zinc ≈ 6–18 months (rain, salt, handling affect it). Packaging is coil/spool—easy to transport and use, which sounds trivial until you’ve lost an hour untangling.

| Vendor | Origin & Traceability | Customization | Certs | Lead Time |

|---|---|---|---|---|

| Tike Metal | Hengshui, Hebei; batch-coded coils | Diameter, hardness, spool, coating | ISO 9001; RoHS/REACH | ≈ 7–15 days |

| Reseller X | Mixed suppliers; limited trace | Limited | Basic COC | Stock-dependent |

| Local Stockist | Local inventory | Cut-to-length only | Varies | Same-day pickup |

Customization usually means dialling in diameter (say 0.45 vs 0.50 mm), temper (so it doesn’t kink), coating, and coil length. A packaging plant told me their switch to 0.55 mm zinc high-carbon Cutting Wire cut breakage by around 27%—just from tighter tolerance and better spooling. Another contractor swapped to 316 Cutting Wire for seaside jobs; yes, it costs more, but the corrosion calm was worth it.

Bottom line: pick the wire to match the job, not the other way around. And pack an extra spool; I guess that’s the veteran move.

RELATED PRODUCTS