As industrial design and architectural decoration evolve, decorative perforated metal sheets (also called perforated wire mesh or hex perforated metal) have become indispensable in modern engineering, creative facades, and high-performance filtration systems. This comprehensive article presents the latest trends, specifications, technical advantages, manufacturing processes, industry standards, and a data-driven comparison of market-leading solutions like the Perforated Metal Mesh.

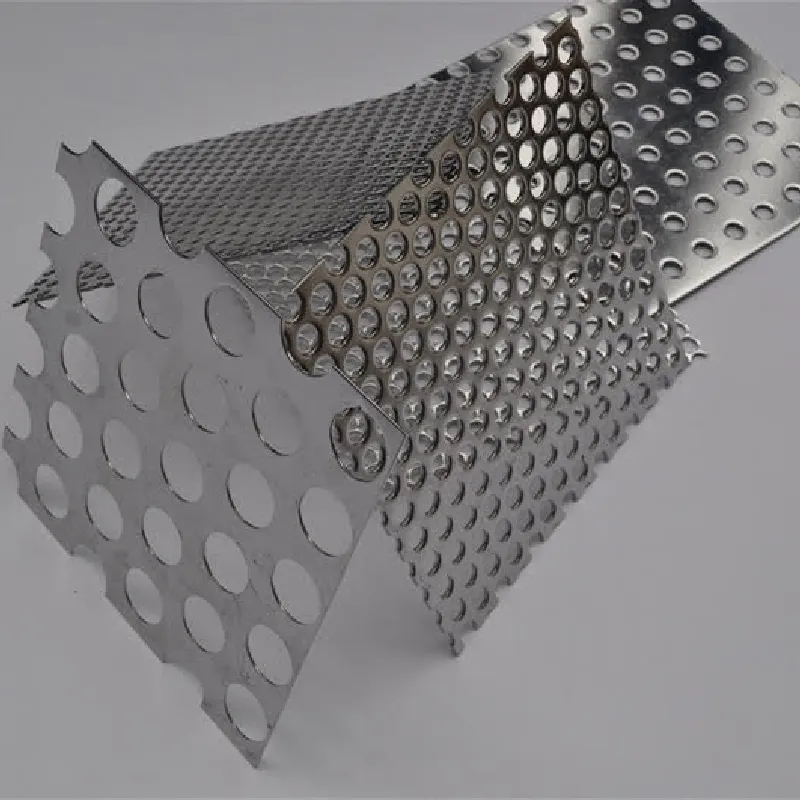

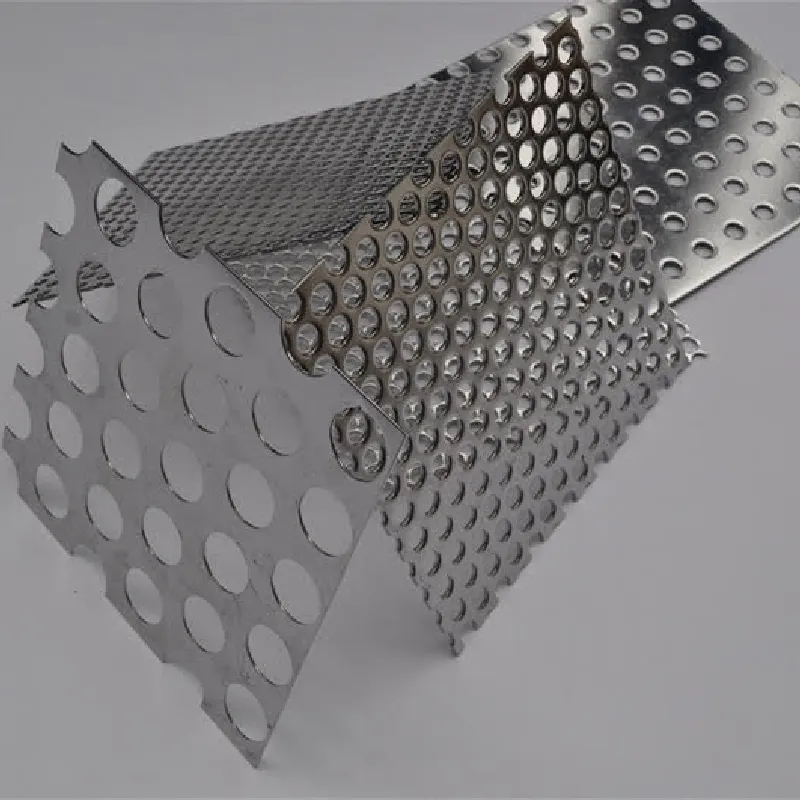

Patterned decorative perforated metal sheets for architectural applications

1. Industry Overview & Trends

The global decorative perforated metal sheets market is witnessing robust growth, driven by applications in modern architecture, energy-efficient facades, safety barriers, and creative design panels. According to Market Research Future, the global market for perforated metals will surpass USD 7.8 billion by 2030, registering a CAGR of 5.5% (2023-2030). Major industries leveraging these products include:

- Architecture and interior design (facades, partitions, ceilings)

- Petrochemical & metallurgical plants

- Water supply and drainage infrastructure

- Food processing, HVAC, automotive, and sound-absorbing systems

- Public transport & infrastructure (railings, ventilation grilles)

New advances in perforated wire mesh—like micro-perforation, surface powder coating, and anti-corrosive treatments—are broadening usage and improving lifecycle cost-effectiveness.

Perforated wire mesh with round and square holes for filtration

Global Perforated Metal Market: Growth Forecast 2023-2030 (USD Billion)

2. What Are Decorative Perforated Metal Sheets?

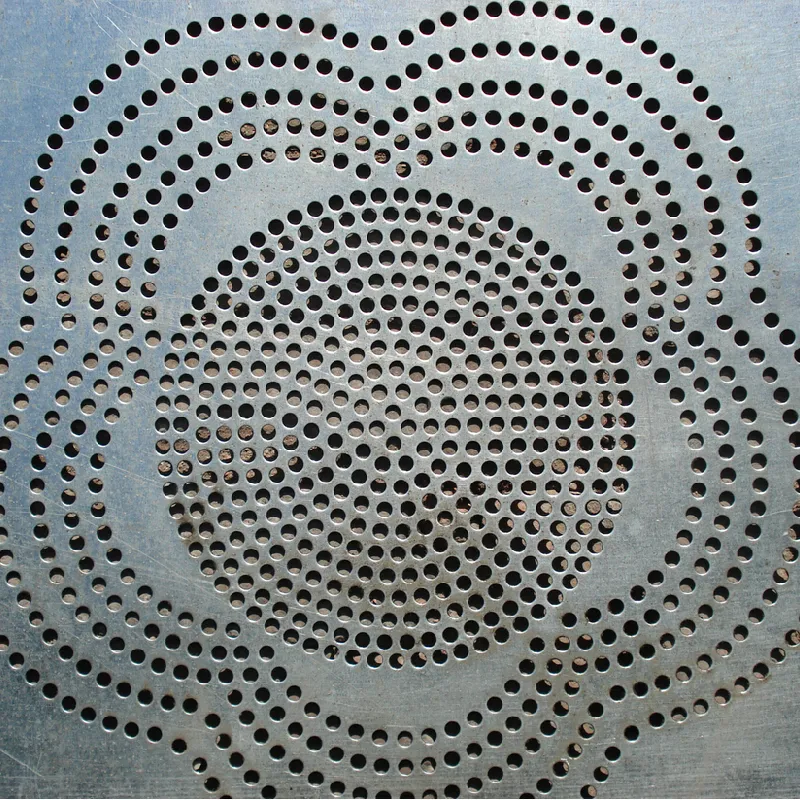

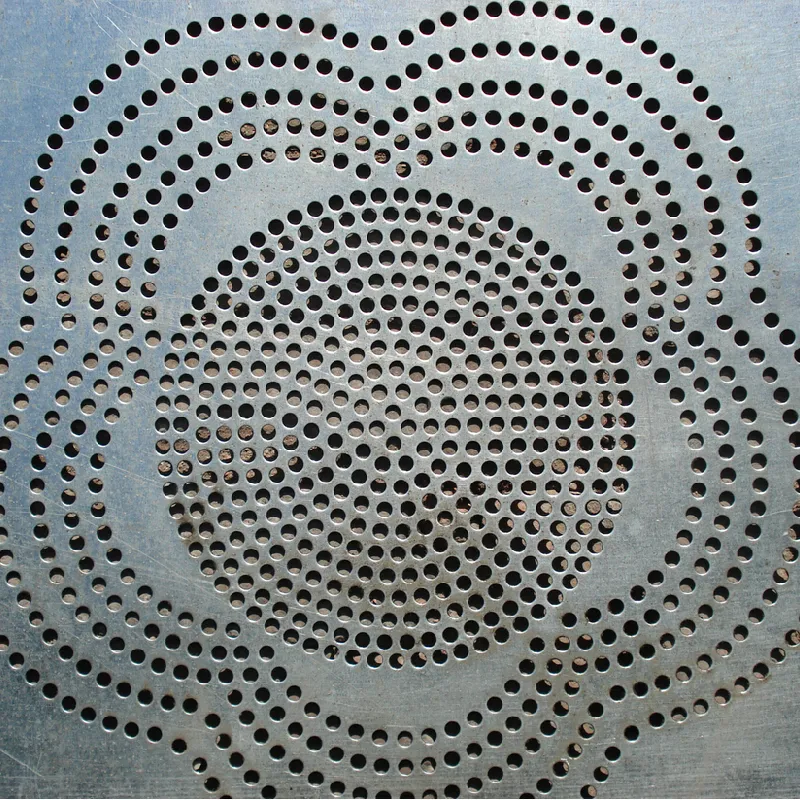

Decorative perforated metal sheets consist of metal panels punched or CNC-cut with custom patterns (round, hexagonal, slotted, or irregular) for both structural and aesthetic purposes. Also known as perforated wire mesh and hex perforated metal, these sheets combine modern design with advanced performance: they can be produced in stainless steel, aluminum, galvanized iron, copper, brass, and even titanium alloys.

Typical applications include exterior facades, interior wall cladding, privacy partitions, sunlight control panels, sound insulation, and ventilation grilles.

Hex perforated metal panel for sunlight shading systems

Key Advantages

- Enhanced design flexibility with customizable shapes and perforation patterns

- Superior strength-to-weight ratio compared to non-perforated panels

- Excellent ventilation and acoustic performance for public spaces

- Corrosion and abrasion resistance (especially for stainless and coated options)

- Long service life with minimal maintenance

- Compliance with international standards (ISO 9001, ASTM, ANSI)

3. Manufacturing Process of Decorative Perforated Metal Sheets

Raw Material Selection

Stainless Steel, Aluminum, etc.

→

Sheet Flattening

→

Perforation

CNC Punching / Laser Cutting

→

Trimming & Edge Treatment

→

Surface finishing

(Powder Coating / Anodizing)

→

Inspection (ISO/ANSI Standards)

→

Packaging & Shipping

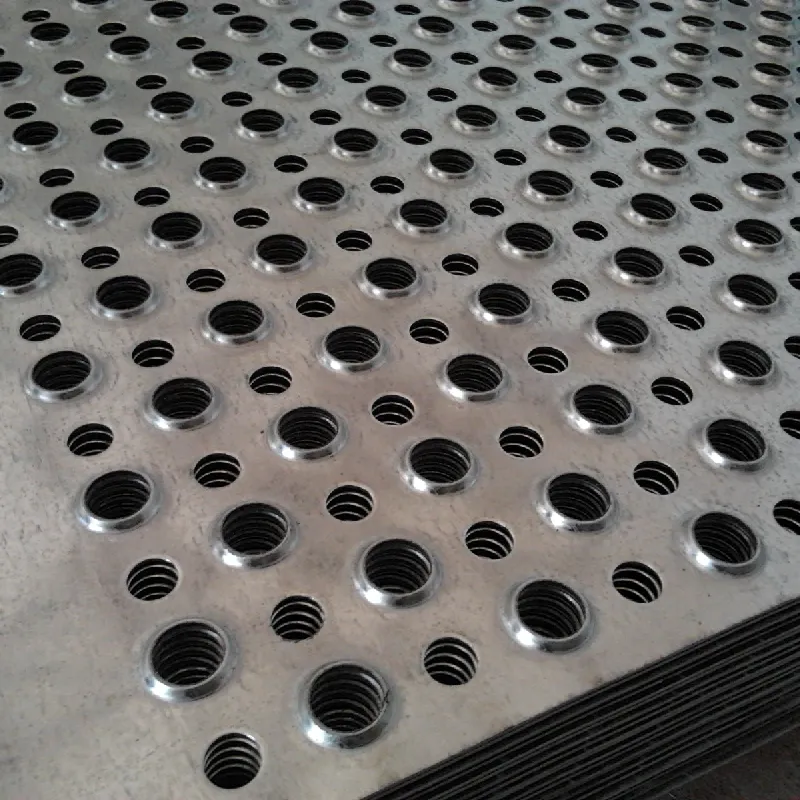

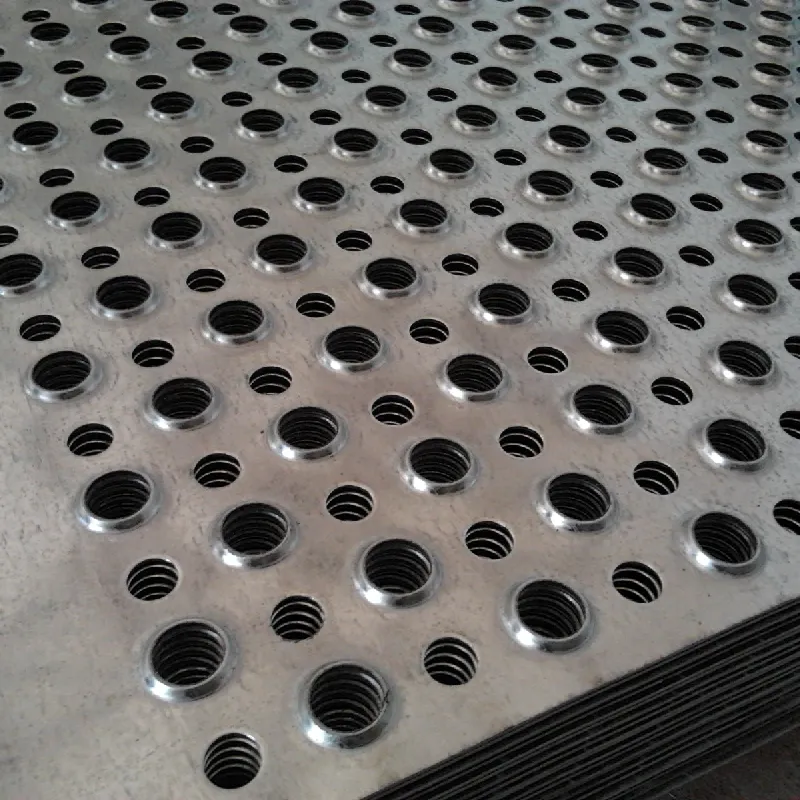

Process Deep Dive: The essential steps begin with material selection (grade 304/316 SS for anti-corrosion, 1100/5052 aluminum for lightweight design). Sheet flattening ensures optimal surface planarity. CNC punching or laser cutting (with minimal heat-affected zone) is used for accurate perforation. Edges are deburred for safety. Advanced surface coatings (E-coat, powder/plasma, or anodizing) can be applied for desired finishes. Every sheet undergoes strict inspection as per ISO 9001 and ASTM A240 standards, ensuring consistent quality and lifespan.

For a detailed process visualization:

Watch this animated production video.

Automated CNC punching line for decorative perforated metal sheets

4. Technical Specifications: Parameter Reference Table

The following table summarizes key specifications for mainstream decorative perforated metal sheets products:

| Parameter | Typical Value | Options/Notes |

|---|

| Material | SS304, SS316, Aluminum 1100/5052, GI, Copper, Brass | Custom alloys available |

| Sheet Thickness | 0.5 – 5 mm | Special up to 12 mm |

| Width | Up to 2000 mm | Standard: 1000/1220/1500 mm |

| Length | Up to 6000 mm | Customizable |

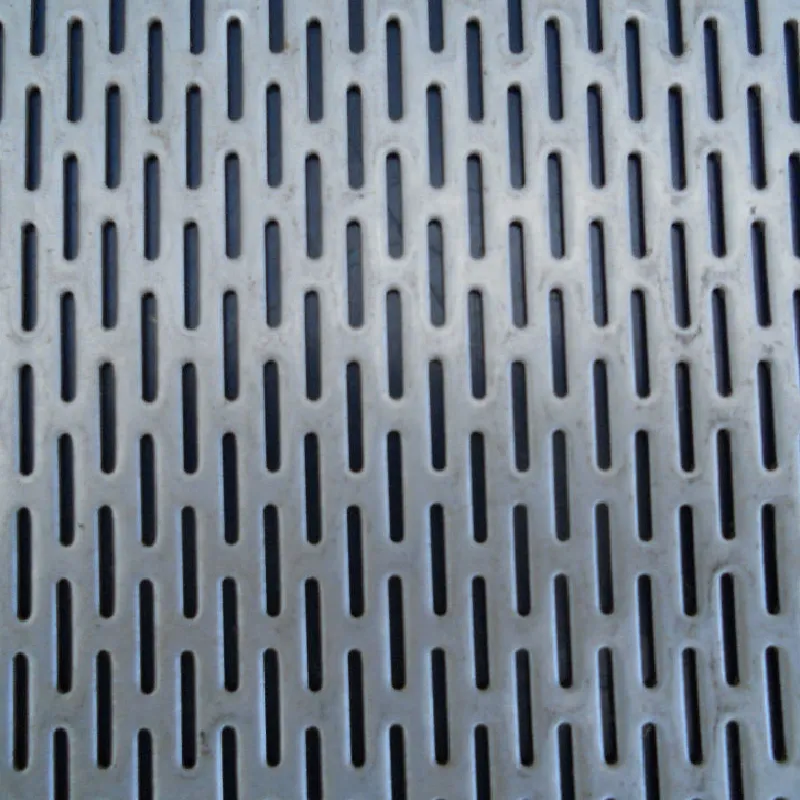

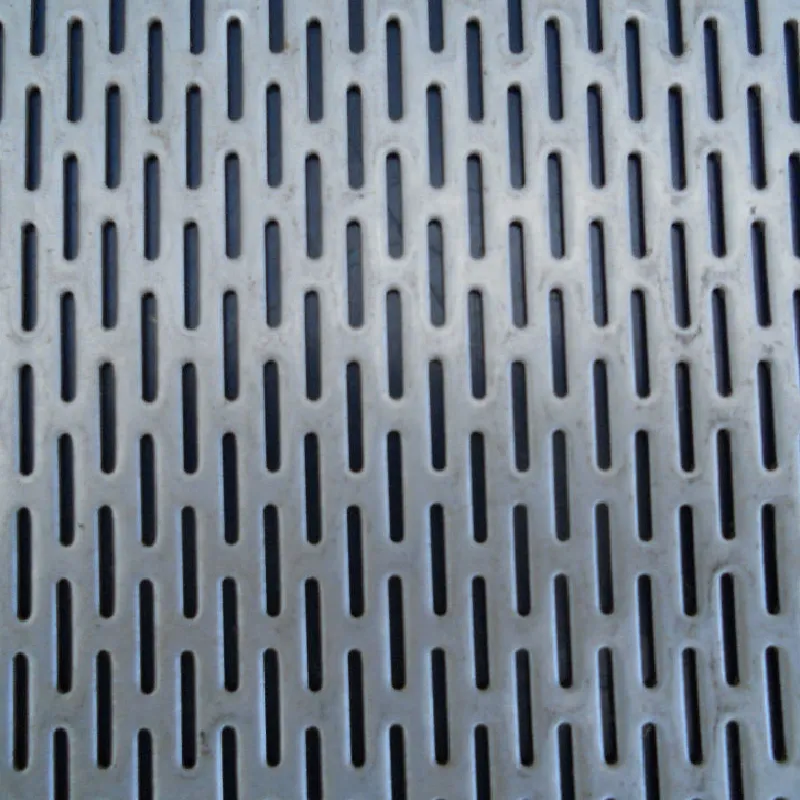

| Hole Type | Round, Square, Hexagonal, Slot, Custom | Any pattern by CNC |

| Open Area (%) | 5 – 60% | Design dependent |

| Surface Finish | Mill, Anodized, Powder-Coated, PVDF | RAL/Pantone colors |

| Corrosion Resistance | Excellent (SS, Anod. Alu) | ISO 9227 tested |

| Compliance | ISO 9001, ASTM A240, ANSI MH26.2 | On request: EN, FDA, SGS |

Perforated metal mesh specification display in workshop

5. Comparative Analysis: Perforated Metal Mesh vs. Hex Perforated Metal

Feature Comparison: Traditional vs. Hex Perforated Designs

| Feature | Round/Square | Hex Perforated |

|---|

| Open Area / Airflow |

Medium (up to 33%) |

High (up to 48%) |

| Design Complexity |

Standard shapes, simple punch |

Modern look, flexible CNC |

| Strength-to-Weight Ratio |

Good, depends on pitch |

Excellent due to honeycomb |

| Application Scenarios |

General partition, filters |

Architectural, airflow control |

| Material Cost |

Lower |

Slightly higher |

Hex perforated metal installed as building facade in commercial project

Featured Product: Perforated Metal Mesh by Tikemetal — an industry-certified, customizable, and highly aesthetic solution with proven excellence in architecture, filtration, and structural design.

Technical Highlights

-

Materials: SS304/316, aluminum alloys (1100, 3003, 5052), carbon steel, galvanized, copper, brass.

-

Typical Sizes: 1.0–4.0 mm thickness, 1220x2440 mm or roll/sheet.

-

Perforation: Punching diameter from 0.5–30 mm, pitch and spacing per requirement (HEX, ROUND, SQUARE).

-

Surface Finish: Mirror, satin, anodized, powder coated (RAL/Pantone), wood-grain/printable.

-

Compliance: All lots tested to ISO 9001, ASTM A240/A480, EN-ISO 9227 (salt spray), ANSI MH26.2.

-

Lifespan: 15–30 years+ under ISO 9227 neutral salt spray (SS, aluminum).

-

Special Features: Sound absorption (NRC>0.8 possible), custom logo integration, laser cut branding.

Material Distribution in Decorative Perforated Metal Sheets Projects (by % Volume, 2023 Data)

Certification & Quality

- ISO 9001:2015 quality system—full traceability from coil to finshed panel.

- Inspected by SGS, TÜV, SGS, and in-house lab to ASTM, EN, and ANSI standards.

- Serving >6000 clients globally (USA, EU, ME, Asia). References: L’Oreal, China State Construction, ENI Group.

- Over 19 years’ export and custom engineering service.

Warranty: All decorative perforated metal sheets are covered by a 5–10 year anti-corrosion guarantee with technical support for installation.

7. Customization & Engineering Support

- Custom hole shapes/patterns (upload DWG, PDF, or image)

- Color-matching (RAL, Pantone, wood-grain effects, anti-fingerprint)

- CNC folding, laser cutting to specification (±0.1 mm tolerance achievable)

- Special acoustic or airflow designs (per test or code)

- Facade substructure design and mounting systems (including hidden fixing)

8. Application Scenarios & Case Studies

Commercial Building Facade (France, 2023)

Petrochemical Plant Screen (Turkey, 2022)

- Material: 304 stainless steel, 3.0 mm thick, round perforation

- Chemical-resistant powder coating, conforming to ISO 9227 salt spray standards

- Function: Durability, anti-corrosion, and safety screening on equipment platforms

- Projected service life: 18+ years (as per testing)

Subway Ventilation Panels (USA, 2021)

- Material: Galvanized steel, PVDF coated, vandal-resistant mounting

- Perforation: Custom airflow slots, 32% open ratio

- Outcome: Improved underground ventilation by 21% vs. welded mesh (per city air quality report)

9. Product vs. Competitor Table

| Criteria | Perforated Metal Mesh (Tikemetal) | Generic Product |

|---|

| Sheet Flatness |

±0.1 mm (ISO 9445 verified) |

±0.25 mm |

| Customization Range |

Full (shape, color, slot size) |

Limited (standard holes only) |

| Service Life |

≥15 years (ISO 9227) |

6–8 years |

| Surface Finish |

Anodized, powder, PVDF, wood grain |

Mill or paint finish |

| Third-party Certification |

ISO/ASTM/SGS/TÜV |

Basic ISO or none |

| Engineering Support |

Project & installation consultancy |

Not included |

| Global Customer Base |

6000+ clients (L'Oreal, ENI, CSCEC, etc.) |

Regional |

10. Delivery, Warranty & Customer Support

- Standard Delivery: 7–15 days after drawing approval (ex-works)

- Global Shipping: Export experience to 40+ countries, CIF/DDP/FOB available

- Warranty: 5–10 years anti-corrosion, on-site technical support

- Customer Support: Engineering advice, custom drawing design, fast RFQ response (within 12 hours)

- After-sales: Installation guide, spare parts, and urgent delivery channels available

11. FAQ: Technical Expertise on Decorative Perforated Metal Sheets

Q1: What are the most common materials for decorative perforated metal sheets and why?

A1: Stainless steel (grades 304, 316) for anti-corrosion; aluminum (lightweight, formable); galvanized steel (economical), and architectural brass/copper for color/appearance.

Q2: What does “open area percentage” refer to in perforated panels?

A2: “Open area” is the ratio (%) of punched hole area to total sheet area; key for airflow, light diffusion, and filtering properties. Architects typically choose 10–45% open area based on use.

Q3: How are hex perforated metal and round perforated panels different?

A3: Hex patterns offer greater open area and a modern honeycomb look, also slightly improved strength-to-weight due to geometry; round holes are traditional and simpler to manufacture.

Q4: Are there specific standards for perforated metal production?

A4: Yes. ISO 9001 (quality), ASTM A240/A480 (materials, flatness), ANSI MH26.2 (structural), and EN ISO 9227 (corrosion testing) — always insist on certified products for critical uses.

Q5: What surface finishes are available and how does coating affect durability?

A5: Options: mill, anodized, powder coating (with 800+ color choices), PVDF, wood-grain, anti-graffiti. Premium coatings (e.g., Akzo Nobel) increase lifespan and resist UV, chemicals.

Q6: What installation methods are used for panels on facades?

A6: Direct mechanical fasteners (countersunk screws, rivets), hidden brackets, frame-mount, or suspension (for ceilings/façades). Engineering drawings ensure aesthetics and strength.

Q7: What is the usual tolerance for panel cutting and hole positioning?

A7: CNC fabrication achieves panel dimensions ±0.1 mm, hole position ±0.2 mm, verified per ISO/ASTM specs. Critical for modular and facade integration.

12. References & Further Reading