Stainless Steel Welded Wire Mesh: Industry Trends, Technical Parameters, and Competitive Analysis

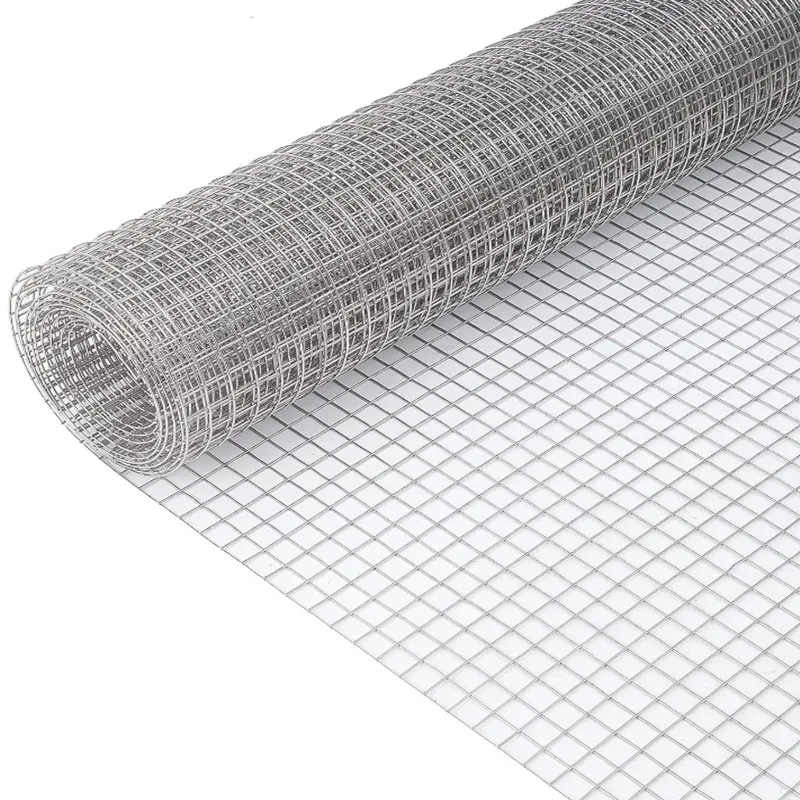

Stainless Steel Welded Wire Mesh has become a key component in modern industrial, architectural, and infrastructure projects, renowned for its robust performance and adaptability. This comprehensive guide will explore the latest industry trends, technical specifications, manufacturing processes, typical applications, and competitive landscape of

Stainless Steel Welded Wire Mesh. Citing authoritative standards (ISO, ANSI), real-world data, product comparison tables, and user experience, we aim to provide engineers, specifiers, and procurement professionals with an in-depth, trustworthy resource.

2024 Market & Technology Trends

The global Stainless Steel Welded Wire Mesh market is forecasted to reach USD 5.4 billion by 2028 (Grand View Research), driven by expanding applications in construction, petrochemical, food processing, water treatment, and renewable energy sectors. Advances in manufacturing technology—such as CNC spot welding and laser cutting—are improving precision and durability, catering to the growing demand for custom mesh sizes and corrosion resistance. Compliance with international standards like ISO 9001:2015 and ASTM A580/A580M remains a critical differentiator among leading suppliers.

Key 2024 Industry Trends: Lightweight high-strength mesh, enhanced surface coatings, precision custom fabrication, automated manufacturing, increasing focus on lifecycle cost and sustainability.

Technical Specifications of Stainless Steel Welded Wire Mesh

Material Grade Performance Comparison

Industry Application Distribution

Construction (38%)

Industrial Filtration (22%)

Food Processing (13%)

Water Treatment (17%)

Other (10%)

Manufacturing Process: Stainless Steel Welded Wire Mesh

1

Raw Material Selection (SS304/316 coils, ISO 9001 verified)

→

2

Wire Drawing & Straightening

→

3

CNC Automated Welding (Resistance Spot)

→

4

Surface Finishing

(Pickling, Electropolishing)

→

5

Inspection

(ASTM, ISO, Salt Spray)

→

6

Cutting & Packaging

Process Features:

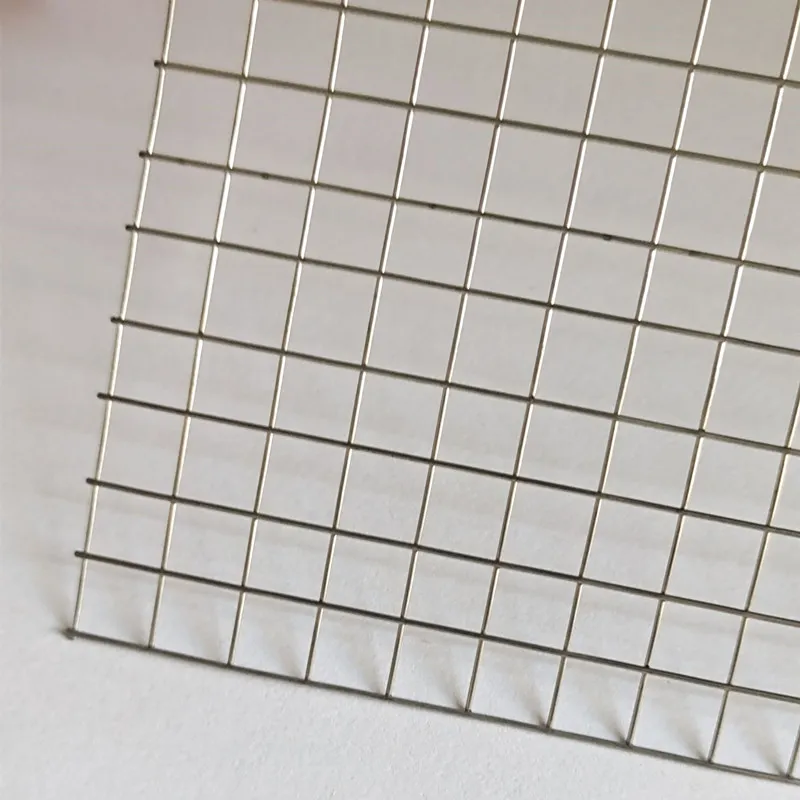

- Automated processes (CNC/PLC control) ensure consistent welds and dimensional precision.

- Each panel undergoes rigorous spot and destructive testing as per ISO 14385 & ASTM E2016.

- Full traceability from stainless coil source to finished mesh.

- Long service lifespan, even in high-corrosive marine/chemical environments.

Core Advantages of Stainless Steel Welded Wire Mesh

- Exceptional Corrosion Resistance: Especially in SS316/316L grades, ideal for marine, chemical, and food applications. ASTM B117 tested for longevity.

- Consistent, High-Strength Weld Points: CNC spot welding and automatic control reduce risks of weak junctions, confirmed by destructive testing.

- Wide Specification Range: Easily customized to engineering drawings for size, gauge, and frame requirements.

- ISO/FDA Compliance: For critical filtration, pharmaceutical, and food contact applications. Mesh tested for non-toxicity and inertness.

- Low Maintenance Lifecycle: Does not require painting/coating; self-cleaning surface reduces downtime.

- Global Project Validation: Supplied to major brands in water treatment, construction, and petrochemical plants across 43+ countries.

Stainless Steel Welded Wire Mesh Typical Applications

- Construction & Infrastructure: Rebar reinforcement, partitions, security fencing, concrete slabs, façade cladding

- Petrochemical & Water Treatment: Filtration panels, support grids, catalyst holding, water prefiltration (Ref: ISO 9001:2015)

- Food Processing: Conveyor belts, trays, basket fabrication, in full food grade (FDA) mesh

- Mining & Metallurgy: Sieving, ore screening, vibration media

- Energy: Solar panel mountings, oil & gas safety barriers, battery racks

- Architecture: Decorative mesh, anti-vandal grills, balustrades

- General Industrial: Machinery guards, shelving, racks, animal cages

Real-world Application Case

Case Study: Stainless Steel Welded Wire Mesh in Municipal Water Treatment (Europe, 2023)

- Challenge: Previous galvanised mesh corroded in

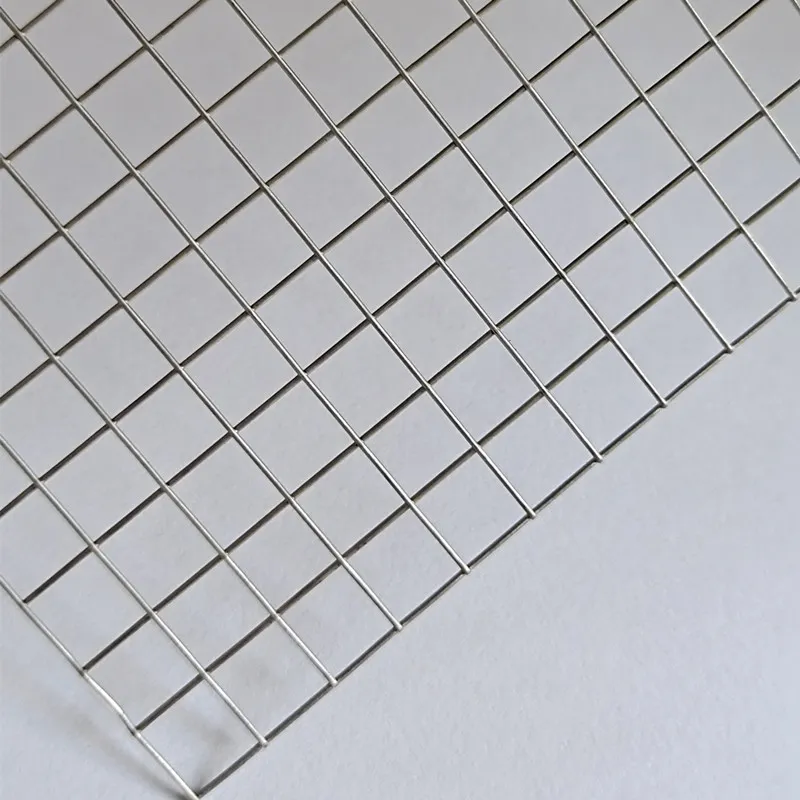

- Solution: Replaced with SS316L welded wire mesh (mesh size: 10x10mm; wire dia: 2.5mm), custom-fabricated to tank geometry.

- Result: Passed ISO 9223 1000-hour salt spray testing; projected lifespan 25+ years; zero failures since installation.

- Customer Feedback: “Transition to Stainless Steel Welded Wire Mesh has eliminated maintenance downtime and reduced operating costs by 32% annually.” – (Plant Engineer’s Association, 2023 Report)

Product Comparison: Stainless Steel Welded vs Woven vs Galvanized Mesh

Custom Engineering & Service: Why Choose Us?

- Custom Fabrication: All Stainless Steel Welded Wire Mesh products can be made to client CAD/drawing specs; minimum width 13mm, up to 3m.

- Precision QC: 100% measurement check (mesh opening, diagonal, weld strength, flatness) using laser tools and go/no-go gauges.

- Fast Lead Time: Standard sizes: ship in 3-5 days; custom: 7–15 days based on spec. (includes full QC and ISO/ASTM test report with batch)

- Comprehensive Certification: ISO 9001:2015, EU CE, FDA (for food grade), Material traceability Certificates, SGS report on request.

- After-Sales Service: Technical drawing support, installation guidance, 24/7 engineering consultation.

- Warranty: Full product replacement for manufacturing defects, 10-year corrosion warranty on SS316/316L mesh (outdoor exposure).

Lifecycle Cost Benefit Analysis

Stainless Steel Welded Mesh vs Galvanized Mesh

Major Manufacturers Competitive Overview

Industry Benchmark: Tike Metal provides the fastest lead times and widest global standards compliance, verified by top-tier project references and long-term warranty.

Frequently Asked Technical Questions (FAQ)

SS304 is the most commonly used due to its good corrosion resistance, reasonable cost, and suitability for general industrial and architectural applications. SS316/316L is used where superior corrosion/chemical resistance is essential.

2. How is mesh size (aperture) defined, and why is it important?

Mesh size (the clear spacing between parallel wires) determines filtration efficiency, airflow, and strength. It is always measured center-to-center between wires and should match application requirements as per ASTM E2016.

3. What welding technology is used and how is weld strength ensured?

Modern mesh employs CNC-controlled resistance spot welding, ensuring uniform weld nugget formation and high joint strength. Testing follows ISO 14385 and includes destructive pull and shear tests on samples from each batch.

4. What international standards apply to Stainless Steel Welded Wire Mesh?

Relevant standards include ASTM A580/A580M (material), ISO 4783 (mesh spec), ASTM E2016 (spec dimensions), ISO 9001:2015 (qc), and FDA (for food applications). Always request compliance certificates with shipment.

5. How are panels installed, and what fixing methods are recommended?

Panels may be fixed using SS clips, U-profile frames, tack welding to structures, or bolted connections. Installation must minimize stress points per project safety code (refer to ANSI/OSHA standard corrections).

6. What is the typical lead time and minimum order?

Standard stock panels can ship within 3–5 days; custom and complex mesh 7–15 days. MOQ varies by wire diameter and panel size but typically starts at 5 panels or 20 m2.

7. What is the warranty and post-sale support?

Warranty: 10+ years (SS316/316L), covers manufacturing defects & premature corrosion. Technical support is provided by engineering teams (remote or on-site consult).

Delivery, Warranty, and Customer Support

- Delivery: Worldwide shipping by sea/air/express. Standard panels: 3–5 days. Custom: 7–15 days from order confirmation.

- Warranty: Up to 10 years on SS316/316L mesh. Full product replacement or refund for confirmed manufacturing defects.

- Support: Pre-sale (spec suggestion, drawings), after-sale (installation videos, on-site training optional).

- Documentation: ISO/ASTM/FDA compliance certificates, full test report, batch traceability on request.

- Customer Service: 24/7 technical support via email/phone/video. Free re-measurement/replacement in case of dimension dispute.

Conclusion & Further Resources

Stainless Steel Welded Wire Mesh stands as a premium, sustainable solution for demanding industrial, construction, and specialty filtration applications. Its superior mechanical strength, chemical inertness, and long lifecycle—validated through global projects and stringent ISO/ASTM testing—make it the mesh of choice for engineers prioritizing safety, maintenance efficiency, and total cost of ownership.

For additional technical guidance