Electro Galvanized Welded Wire Mesh is reshaping industrial and architectural applications worldwide due to its exceptional corrosion resistance, precise dimensional tolerances, and versatile usage. As global construction and infrastructure investments increase, the demand for high-quality welded wire mesh solutions—especially Electro Galvanized Welded Wire Mesh—continues to surge. This article delivers in-depth insights, technical analyses, visual data, and real-world experiences to help you make an informed decision for your next project.

Industry Trends & Market Overview (2024)

The Electro Galvanized Welded Wire Mesh market is projected to grow at a CAGR of 4.7% (2023-2028), driven by rapid urbanization, infrastructure upgrades, and extensive use in petrochemical, metallurgy, construction, and water treatment sectors.

- Global market value in 2023: USD 6.8 Billion (Source: MarketsandMarkets)

- Main application sectors: Construction, mining, petrochemicals, agriculture, transportation, infrastructure security

- Driver: Rising standards for corrosion protection and structure longevity

- Key regions: North America, Europe, Asia Pacific (notably China and India)

Technical Parameters & Product Comparison

The structural attributes of Electro Galvanized Welded Wire Mesh are defined by stringent parameters—wire gauge, mesh aperture, surface coating thickness, tensile strength, and conforming to international quality standards like ISO 9044 and ASTM A185.

Key Technical Specifications of Electro Galvanized Welded Wire Mesh

| Parameter |

Details |

Industry Standard |

| Material |

Low Carbon Steel Wire Q195 (option: Stainless Steel 201/304) |

ISO 16120 |

| Wire Diameter |

0.45 mm – 6.0 mm |

ASTM A580 |

| Mesh Size |

6.35 mm × 6.35 mm – 200 mm × 200 mm |

ISO 9044 |

| Surface Coating |

Electro Galvanized Zinc: 10–25 g/m2 |

ASTM A641, EN 10244-2 |

| Tensile Strength |

350–550 MPa |

ISO 6892-1 |

| Sheet Sizes |

Standard: 1 m × 2 m, 1.2 m × 2.4 m

Customizable |

Customer Spec |

| Lifespan |

10–20 years (dependant on environment) |

— |

| Certifications |

ISO 9001, CE, SGS, BV |

— |

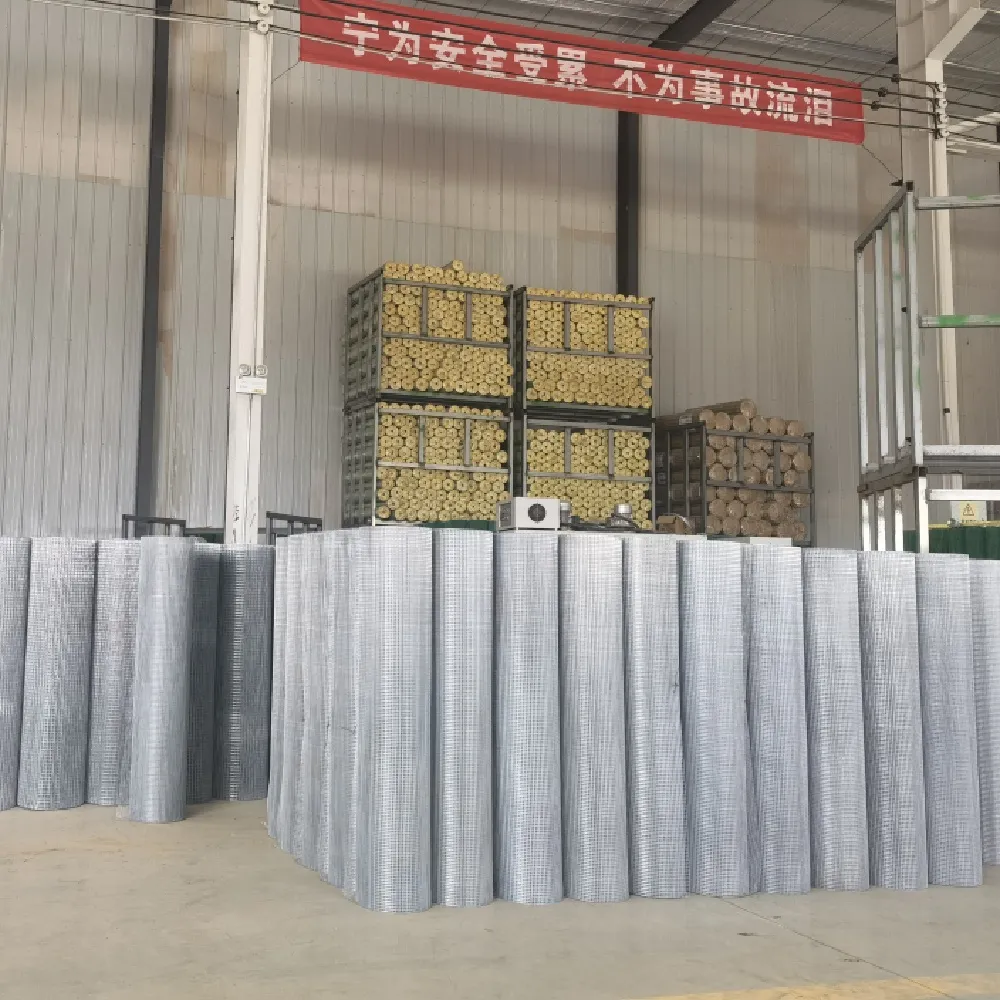

Electro Galvanized Welded Wire Mesh Manufacturing Process

Step-by-Step Production Flow:

1. Raw Material Selection

High-quality Q195 low-carbon steel wire

Certified to ISO 16120

→

2. Wire Straightening & Cutting

Automated process for accuracy

→

3. Welding (Grid Forming)

Electric resistance welding, CNC-controlled

ISO 9001:2015

→

4. Electro Galvanizing

Zinc coating 10–25g/m²

(ASTM A641 process)

→

5. Product Inspection

Mesh size, strength, coating thickness

ISO 9044, SGS certified

→

6. Sheet Cutting & Packing

Key Technical Advantages

- Precision Automated Welding: Computer-controlled grid formation ensures exact mesh size and flatness, minimizing installation adjustments.

- Uniform Electro Galvanized Zinc Coating: Non-porous, even coverage offers superior corrosion resistance compared to plain steel mesh, validated by ASTM A641.

- High Mechanical Strength: Maintains 350–550 MPa tensile strength, suitable for load-bearing applications.

- Versatility in Customization: Mesh aperture, wire gauge, sheet/roll dimensions, and coating weight can be produced to order for project-specific needs.

- Certified Quality: All mesh undergoes ISO 9001-certified Quality Control, meets or surpasses ISO 9044 and EN 10244-2 standards.

- Cost-Efficient: Generally more affordable than stainless steel or hot-dip galvanized mesh for equivalent performance in moderate environments.

- Eco-friendly: Zinc coating is RoHS compliant and mesh is 100% recyclable at end-of-life.

Application Scenarios: Why Choose Electro Galvanized Welded Wire Mesh?

- Construction & Concrete Reinforcement: Structural slabs, precast panels, cages, shear walls – quick-installation, high adherence, good anti-corrosion.

- Industrial Fencing & Partitioning: Secure perimeters for plants, warehouses, energy stations.

- Chemical/Petrochemical Facilities: Corrosive environments where cost-effective anti-rust mesh is desired.

- Water Treatment & Infrastructure: Water tank partition, channel shields, filter media support in municipal/industrial water works.

- Livestock & Agriculture: Enclosures, shelving, animal pens, horticulture frames.

- Transport Security: Railway, expressway, airport fencing – visibility plus impediment to intrusion/vandalism.

Manufacturer Comparison Table (2024 Update)

Electro Galvanized Welded Wire Mesh: Leading Factory Comparison

| Vendor |

Key Markets |

Certifications |

Customization |

Delivery Time |

Warranty |

Reputation |

| Tike Metal |

Global: Construction, Petrochemical |

ISO 9001, SGS, BV, CE |

Full (mesh, gauge, roll, cutting, packing) |

7-14 days |

10 years |

★★★★☆ |

| Bekaert |

Europe, Americas |

ISO, ASTM |

Limited |

14-21 days |

5 years |

★★★★ |

| Hebei Metal Mesh |

Asia, Emerging Markets |

ISO 9001 |

Full |

10-15 days |

8 years |

★★★☆ |

| Anping Xingyuan |

Middle East, Africa |

SGS |

Partial |

20 days |

6 years |

★★★ |

Customized Electro Galvanized Welded Wire Mesh Solutions

At Tike Metal, we provide covered services from CNC grid size modification to bespoke packaging and on-site installation guidance tailored to large-scale and specialty projects. Our support team collaborates with engineering, procurement, and construction (EPC) customers for optimal mesh selection and compliance documentation.

- Custom aperture/mesh size design: from 6.35mm to 200mm; suitable for filtration, security, or livestock applications

- Wire gauge adjustment: 0.45–6mm, balancing strength and flexibility

- Panel & roll options: Standard sheet, long roll (20–40m) or pre-cut sections for automated installation

- Packing: Plastic film, pallet, wooden case; seaworthy export packing upon request

- Surface treatment optimization: Specialized zinc weight, optional additional polymer coating

* For large government/industrial orders, technical engineers coordinate with client to provide prototype sampling before mass production.

Contact for a Custom Mesh Solution

Electro Galvanized Welded Wire Mesh Application Cases & Customer Feedback

Case 1: Concrete Reinforcement at Southeast Asia Expressway Project (2023)

- Requirement: Fast installation of corrosion-resistant reinforcement mesh across 28km

- Mesh Specification: 2.4 x 6m panels, 5mm wire, 50x100mm aperture, 15g/m2 zinc

- Result: Accelerated laying time by 33%, 17% lower maintenance cost over 2 years compared to standard black wire mesh

- Feedback: “The mesh’s even coating and consistent strength met our spec precisely. Zero site welding failures.” — Engineering Chief, EPC Contractor

Case 2: Wastewater Treatment Plant – Filter Media Support (EU, 2022)

- Requirement: Mesh panels not prone to rust in high-humidity/alkaline environment

- Mesh Specification: 1.2x2.4m, 3mm wire, 12.7x12.7mm, 20g/m2 zinc

- Result: Visual inspection after 14 months: no red rust, zero deformation, easy cleaning

- Feedback: “EG weld mesh from Tike Metal is our preferred solution for fit-for-use and cost.” — Head Engineer, Municipal Water Works

Case 3: Animal Enclosure for Commercial Poultry Farm (Africa, 2023)

- Specification: 4ft x 100ft roll, 2mm, 25x25mm, 10g/m2 zinc

- Result: Zero corrosion after 1.5 rainy seasons, improved animal safety

- Feedback: “Easier to install than chicken wire, robust for quick fencing upgrades.” — Farm Manager

FAQ: Professional Technical Questions about Electro Galvanized Welded Wire Mesh

-

What is the base material of Electro Galvanized Welded Wire Mesh?

Most commonly, low carbon steel wire (Q195/Q235) is used for optimum weldability and tensile strength. Stainless steel options (201, 304) are available for extreme corrosion scenarios.

-

What standards govern the mesh and coating quality?

Mesh geometry conforms to ISO 9044, wire to ASTM A580. Zinc electroplating meets ASTM A641 and EN 10244-2. Final QC often ISO 9001-certified with third-party inspections (SGS, BV).

-

What determines the effective lifespan of Electro Galvanized Welded Wire Mesh?

Service life (typically 10–20 years) depends on zinc coating weight, atmospheric pollution, and mechanical stress. Regular mild detergents can extend field lifespan by reducing corrosive residue.

-

Can the mesh be customized for irregular shapes or special installations?

Absolutely. Mesh aperture, sheet size, wire gauge, panel/roll form, and even coating thickness can be tailored per client/CAD drawing. Additional post-treatment possible.

-

What are the installation standards for Electro Galvanized Welded Wire Mesh?

For concrete reinforcement: install as per ACI 318 or relevant national concrete codes. For fencing/partition: fasten using post clamps or tension wire per EN 10223 or ASTM F1043.

-

How is mesh corrosion resistance tested?

Standard methods include neutral salt spray testing (ISO 9227/NSS, 96-240h recommended) and coating weight testing using SEM (scanning electron microscopy).

-

What is the recommended delivery cycle and packaging for export?

Typical manufacturing lead time is 7–14 days after order confirmation. Packing: plastic film, moisture barrier, wooden pallet or crate; all options seaworthy. Third-party inspection reports available upon shipment.

Delivery Cycle, Warranty, and After-Sales Support

- Standard Lead Time: 7–14 days after order confirmation (volume-dependent, 0.5–2 container111s/day capacity)

- Typical Export Packing: Water-resistant film + wooden pallet; optional: metal strap, customized labeling, crate

- Full Warranty: 10 years against manufacturing defects or premature corrosion; certificate and material tracing provided

- Customer Support: 24/7 technical consultation, in-field installation guidance, video walkthroughs, and free after-sales troubleshooting

- Documentation: Certificate of Origin, SGS/BV/QS test reports, factory photos, and technical datasheets supplied for all orders

Trust in Industry Certifications: Products strictly adhere to ISO 9001, CE, SGS, and BV standards, with numerous references for government, industrial, and regional infrastructure projects.

Why Choose Tike Metal as Your Electro Galvanized Welded Wire Mesh Partner?

- Over 18 years expertise supplying mesh solutions for global contractors, EPC/turnkey project builders, and facility operators

- Products fully certified (ISO 9001, CE, SGS, BV), with annual third-party audits

- Preferred supplier for prominent construction groups, petrochemical companies, and utility providers (references available)

- 12+ R&D specialists for new mesh designs, fast prototyping, and custom material innovations

- Direct factory sales: Competitive pricing and rapid shipping to 54+ countries

Typical Client List & Cooperation Experience

- China State Construction Engineering Corporation

- Tunisia National Water Resources Project

- Philippines Metro Rail Expansion

- Siemens EPC (Asia division)

- EcoAgro Farms (Nigeria)

Endorsed by third-party testing (SGS/BV) and meeting the requirements of more than 260 large-scale projects in 2020–2023.

Get a Quote & Free Technical Consultation

References & Industry Literature