Perforated metal mesh has become an essential material in both industrial and architectural applications due to its unique combination of structural integrity, functional performance, and aesthetic appeal. This article provides an in-depth analysis of the Perforated Metal Mesh product, highlighting its features, technical specifications, and real-world applications. The discussion also includes insights into the company behind this innovation, Shenzhou Tike Metal Co., Ltd., and references to authoritative standards from the National Institute of Standards and Technology (NIST) to reinforce its credibility.

Perforated metal mesh is engineered to deliver exceptional performance across a wide range of applications. Its design and material properties make it a preferred choice for industries requiring durability, precision, and adaptability. Below are the core features that define this product:

The Perforated Metal Mesh is designed to meet precise industrial standards. Below is a detailed specification table outlining its key parameters:

| Parameter | Details |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm - 10mm |

| Opening Rate | 5% - 80% |

| Aperture | 0.5mm - 200mm |

| Hole Distance | 1mm - 200mm |

| Size | 1mx2m, 1.22mx2.44m, 1.5mx3m, etc. |

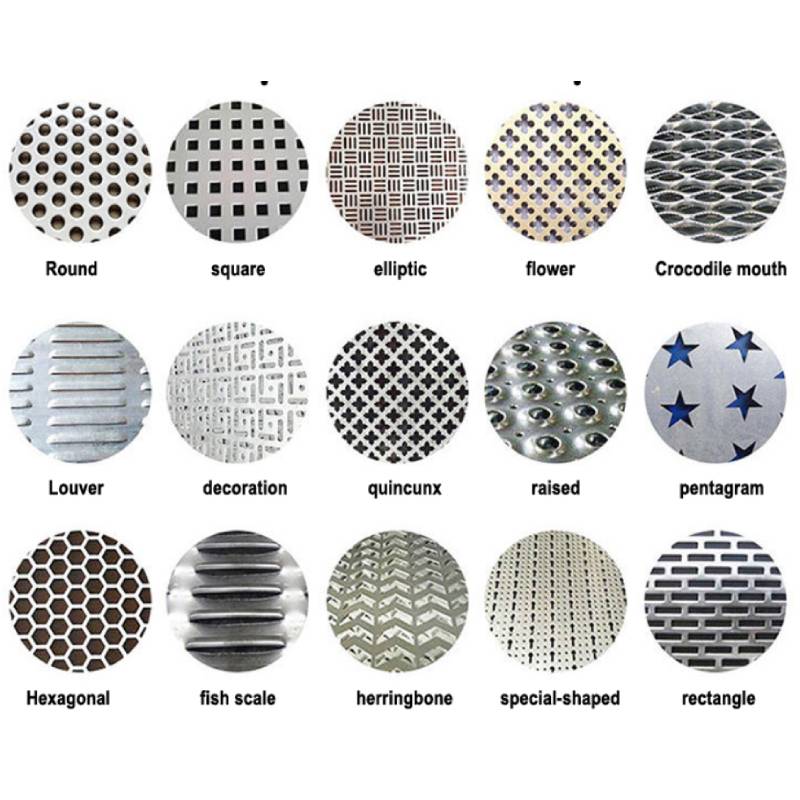

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa / 100MPa |

| Hardness | 150-200HB / 30-50HB |

| Area Density | 20% - 60% |

The versatility of perforated metal mesh makes it suitable for a broad range of applications. Its ability to balance functionality and aesthetics has led to its adoption in both industrial and architectural contexts. Key applications include:

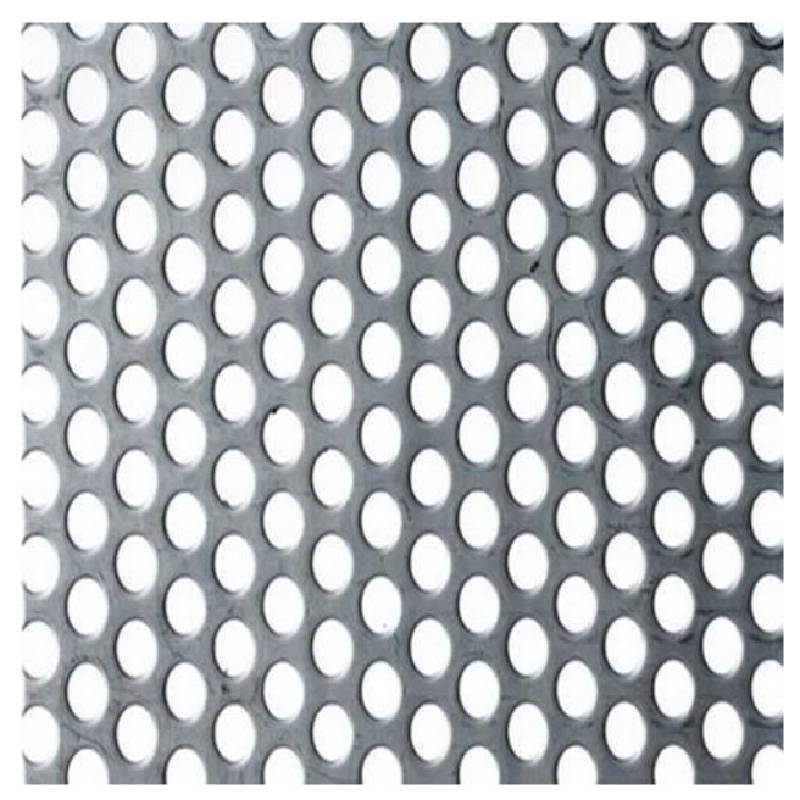

One of the most popular perforation types is the round hole perforation, which offers a balance of strength, airflow, and visual appeal. This design is widely used in applications ranging from industrial machinery to modern architectural features.

Shenzhou Tike Metal Co., Ltd. is a leading manufacturer specializing in high-quality metal products, including perforated metal mesh. With a focus on innovation and precision, the company has established itself as a reliable supplier for both domestic and international clients. Their commitment to quality is reflected in the rigorous testing and production standards applied to their products.

Shenzhou Tike Metal Co., Ltd. leverages advanced manufacturing technologies to produce perforated metal mesh that meets the exacting demands of modern industries. Their expertise in material science and engineering ensures that their products are not only durable but also adaptable to specific application requirements. The company's dedication to sustainability is also evident in their efforts to minimize waste and promote recycling, aligning with global environmental standards.

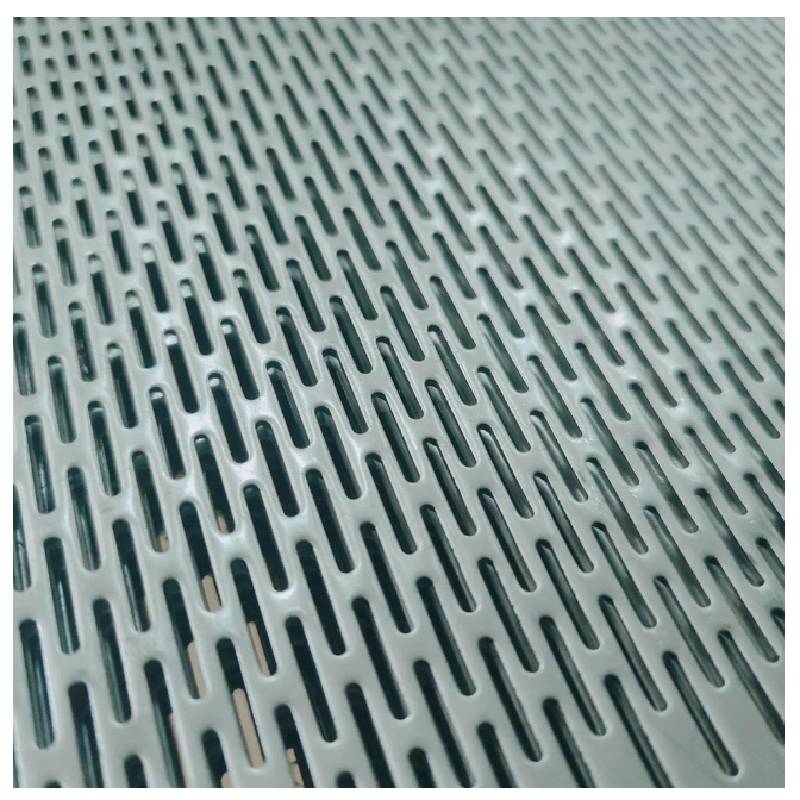

The following images showcase the Perforated Metal Mesh in different configurations:

Image 1: Perforated Metal Mesh - Project 7

Image 2: Perforated Metal Mesh - Project 1

Image 3: Perforated Metal Mesh - Project 4

The Perforated Metal Mesh adheres to international standards for material performance and safety. These standards ensure that the product meets the required specifications for strength, durability, and environmental compliance. For instance, the National Institute of Standards and Technology (NIST) provides critical research and guidelines that inform the development of materials like perforated metal mesh. NIST's work in metrology and material science ensures that industries have access to reliable measurement tools and standards, which are essential for quality control and innovation.

According to NIST, "Precise measurements are the foundation of technological advancement, enabling industries to create products that meet exacting performance criteria" (NIST, 2025). This emphasis on accuracy and reliability is reflected in the production processes of Shenzhou Tike Metal Co., Ltd., where rigorous testing ensures that every batch of perforated metal mesh meets the highest standards.

The Perforated Metal Mesh is a testament to the synergy between engineering innovation and practical application. Its combination of high performance, customization options, and environmental benefits makes it a preferred choice for industries and architects alike. As the demand for sustainable and versatile materials continues to grow, products like perforated metal mesh will play a pivotal role in shaping the future of manufacturing and design.

NIST (National Institute of Standards and Technology). (2025). https://www.nist.gov

Shenzhou Tike Metal Co., Ltd.. (n.d.). https://www.tikemetal.com

Perforated Metal Mesh Product Page. (n.d.). https://www.tikemetal.com/perforated-metal-mesh.html

RELATED PRODUCTS