Perforated metal mesh has emerged as a versatile material in modern industrial and architectural applications, offering a unique combination of structural integrity, aesthetic appeal, and functional performance. This article provides an in-depth exploration of the Perforated Metal Mesh product, its technical specifications, and its wide-ranging applications. Developed by Shenzhou Tike Metal Co., Ltd., this product exemplifies innovation in metal fabrication, meeting the demands of diverse industries.

The Perforated Metal Mesh is engineered to deliver exceptional performance across multiple dimensions. Its design and material composition ensure durability, adaptability, and environmental sustainability, making it a preferred choice for both industrial and architectural projects.

One of the standout features of this product is its high opening rate, which can exceed 30%. This characteristic allows for optimal air permeability and light transmission, making it ideal for applications requiring ventilation or natural lighting. The precise engineering of the perforations ensures minimal obstruction while maintaining structural strength.

Due to its high opening rate, the Perforated Metal Mesh is significantly lighter than solid metal sheets of the same size. This lightweight property reduces material costs and simplifies handling, cutting, and installation processes. It is particularly beneficial for large-scale projects where weight management is critical.

Available in a variety of metal materials, the Perforated Metal Mesh exhibits excellent corrosion resistance. This makes it suitable for use in harsh environments, including industrial settings, marine applications, and outdoor architectural projects. The material's resistance to rust and degradation ensures a long service life, reducing maintenance requirements.

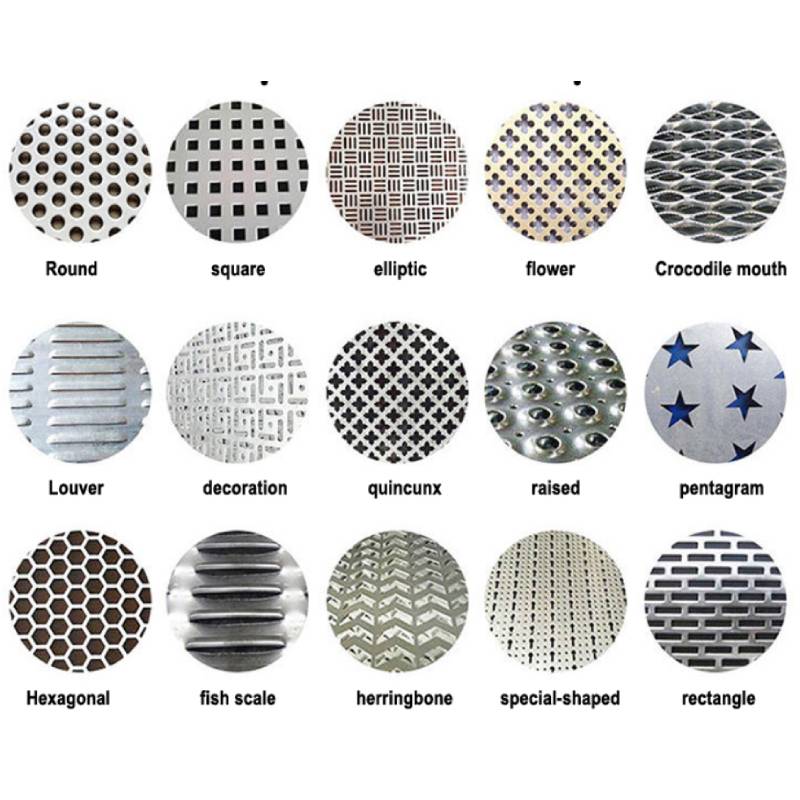

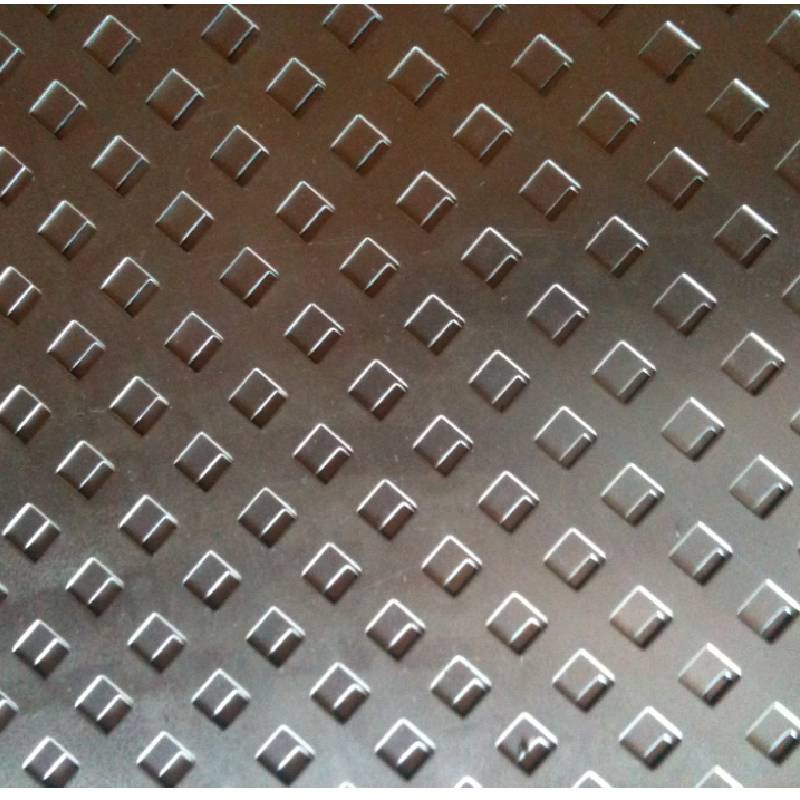

The product allows for customized patterns and shapes, enabling designers to create visually striking elements. Whether it's a geometric design for a modern building facade or a traditional motif for a decorative panel, the Perforated Metal Mesh can be tailored to meet specific aesthetic needs.

The Perforated Metal Mesh is highly versatile, as it can be cut, bent, welded, and processed to fit various requirements. This flexibility makes it suitable for complex designs and intricate installations, such as soundproofing panels, filtration systems, and architectural facades.

As a recyclable material, the Perforated Metal Mesh contributes to environmental sustainability. Its reusability aligns with modern green building practices, making it an eco-friendly choice for industries committed to reducing their carbon footprint.

The Perforated Metal Mesh is designed to meet stringent technical requirements, ensuring reliability and performance in diverse applications. The following table provides a detailed overview of its specifications:

| Parameter | Details |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm - 10mm |

| Opening Rate | 5% - 80% |

| Aperture | 0.5mm - 200mm |

| Hole Distance | 1mm - 200mm |

| Size | 1m x 2m, 1.22m x 2.44m, 1.5m x 3m, etc. |

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa / 100MPa |

| Hardness | 150-200HB / 30-50HB |

| Area Density | 20% - 60% |

These specifications highlight the product's adaptability to various applications, from lightweight filtration systems to heavy-duty structural components. The Perforated Metal Mesh is engineered to balance strength, durability, and functionality, ensuring it meets the demands of modern industries.

The Perforated Metal Mesh is widely used in both industrial and architectural contexts, offering solutions for diverse challenges. Its versatility and performance make it a preferred material for the following applications:

The Perforated Metal Mesh is extensively used in industrial settings for applications such as:

In the architectural domain, the Perforated Metal Mesh is employed for:

The Perforated Metal Mesh is also used in specialized applications such as:

Shenzhou Tike Metal Co., Ltd., the manufacturer of the Perforated Metal Mesh, is a leading player in the metal fabrication industry. With a focus on innovation and quality, the company has established itself as a trusted supplier of advanced metal products. Their commitment to excellence is reflected in the design and performance of the Perforated Metal Mesh, which meets the highest standards of durability and functionality.

Shenzhou Tike Metal Co., Ltd. has a long-standing reputation for delivering customized solutions tailored to the specific needs of its clients. The company's state-of-the-art manufacturing facilities and skilled workforce ensure that each product is produced to exacting standards. Their product portfolio includes a wide range of metal mesh and perforated sheet products, catering to industries such as construction, automotive, and industrial manufacturing.

The Perforated Metal Mesh is a testament to Shenzhou Tike Metal Co., Ltd.'s dedication to innovation and customer satisfaction. By combining advanced technology with a deep understanding of industry requirements, the company continues to set benchmarks in the metal fabrication sector.

The Perforated Metal Mesh has been successfully deployed in various real-world applications, demonstrating its versatility and effectiveness. Below are some examples:

In industrial settings, the Perforated Metal Mesh is used in oil filters and grain sifters, where its high opening rate and corrosion resistance ensure efficient and long-lasting performance. The precise aperture sizes allow for the separation of fine particles, enhancing the quality of the end product.

Architects and designers have utilized the Perforated Metal Mesh to create visually striking facades and interior elements. Its customizable patterns and shapes enable the creation of unique designs that blend functionality with aesthetics. For example, the Perforated Metal Mesh has been used in the construction of modern office buildings, where it provides both natural lighting and a sleek, contemporary look.

The Perforated Metal Mesh is also employed in sound isolation and ventilation systems. Its ability to absorb and diffuse sound makes it an effective solution for reducing noise pollution in industrial and commercial spaces. Additionally, its airflow properties enhance ventilation, ensuring a comfortable and safe environment for occupants.

From railings to partitions, the Perforated Metal Mesh adds a touch of sophistication to architectural spaces. Its customizable patterns and shapes allow for the creation of unique designs that reflect the client's vision. For instance, the Perforated Metal Mesh has been used in the design of artistic installations and public spaces, where it serves both functional and decorative purposes.

The Perforated Metal Mesh offers significant environmental and economic advantages. As a recyclable material, it contributes to sustainable development by reducing waste and conserving resources. The Perforated Metal Mesh is also cost-effective, as its lightweight design reduces transportation and installation costs. Additionally, its durability ensures long-term savings by minimizing the need for frequent replacements and maintenance.

The Perforated Metal Mesh is a versatile and high-performance material that meets the demands of modern industries and architectural projects. Its combination of high opening rate, corrosion resistance, and customizable design makes it an ideal solution for a wide range of applications. Developed by Shenzhou Tike Metal Co., Ltd., this product exemplifies innovation and quality in metal fabrication. Whether used in industrial filtration systems, architectural facades, or soundproofing solutions, the Perforated Metal Mesh continues to set new standards in the industry.

The information provided in this article is based on the technical specifications and product details of the Perforated Metal Mesh product. For additional insights into industry standards and material testing, the National Institute of Standards and Technology (NIST) provides valuable resources on measurement science and standards. While direct links to NIST's website are not available in this context, their work in developing standards for materials and manufacturing processes is widely recognized and referenced in the industry.

Source: National Institute of Standards and Technology (NIST)

RELATED PRODUCTS