Perforated metal mesh has emerged as a critical component in both industrial and architectural applications, offering a unique combination of functionality, aesthetics, and durability. This article explores the Sheet Plate Punching Mesh product, its technical specifications, and its wide-ranging applications. By leveraging advanced manufacturing techniques, this product provides a sustainable and customizable solution for diverse industries.

The Sheet Plate Punching Mesh is designed with a focus on performance and adaptability. One of its standout features is its high opening rate, which can exceed 30%. This characteristic ensures excellent air permeability and light transmission, making it ideal for applications requiring ventilation or natural lighting. Additionally, the mesh's lightweight design—a result of its high opening rate—makes it easier to handle and install compared to solid metal sheets of similar size.

Corrosion resistance is another critical advantage of this product. The mesh can be manufactured from various metal materials, including stainless steel, aluminum, and galvanized steel, each offering robust protection against environmental degradation. This makes it suitable for both indoor and outdoor use. Furthermore, the customizable design allows for unique patterns and shapes, enabling architects and engineers to integrate the mesh into aesthetic and functional structures.

The ease of processing is another key benefit. The Sheet Plate Punching Mesh can be cut, bent, welded, and otherwise modified to meet specific project requirements. This flexibility ensures that the product can be tailored to fit a wide array of applications. Finally, its environmental friendliness is a significant selling point. The mesh is fully recyclable, aligning with global efforts to reduce waste and promote sustainable practices.

| Parameter | Specification |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm - 10mm |

| Opening Rate | 5% - 80% |

| Aperture | 0.5mm - 200mm |

| Hole Distance | 1mm - 200mm |

| Size | 1m x 2m, 1.22m x 2.44m, 1.5m x 3m, etc. |

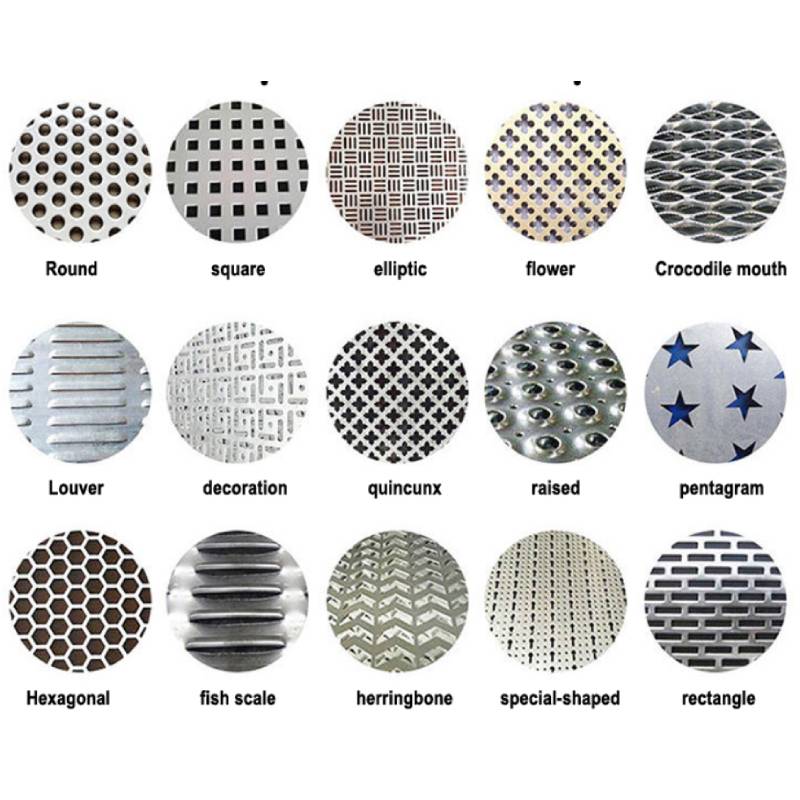

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa / 100MPa |

| Hardness | 150-200HB / 30-50HB |

| Area Density | 20% - 60% |

The Sheet Plate Punching Mesh is widely used in both industrial and architectural contexts. In industrial settings, it serves as a critical component in oil filters, grain sifters, and sound isolation systems. Its high opening rate and durability make it an excellent choice for filtration applications, where it can efficiently separate particles and liquids. In sound management, the mesh helps absorb and diffuse sound waves, reducing noise pollution in industrial environments.

In architectural applications, the Sheet Plate Punching Mesh is employed for ventilation systems, decorative facades, and lighting solutions. Its ability to allow airflow while maintaining structural integrity makes it ideal for ventilation in buildings. The customizable patterns also enable architects to create visually striking designs, blending functionality with aesthetics. Additionally, the mesh's light transmission properties can be leveraged to enhance natural lighting in interior spaces.

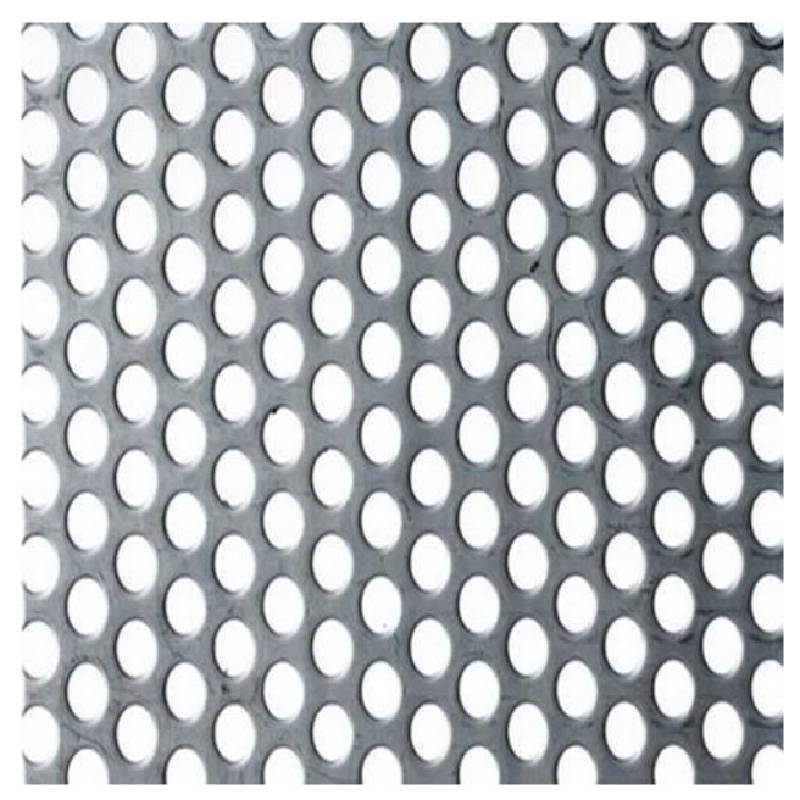

One of the most popular configurations is the round hole perforation, which offers a balance of strength, durability, and aesthetic appeal. This design is commonly used in applications requiring uniform airflow or light distribution, such as in HVAC systems and ceiling panels.

Shenzhou Tike Metal Co., Ltd. is a leading manufacturer of metal products, specializing in the production of Sheet Plate Punching Mesh and other metal mesh solutions. With a commitment to quality and innovation, the company has established itself as a trusted supplier in the global market. Their state-of-the-art facilities and advanced manufacturing techniques ensure that their products meet the highest standards of performance and reliability.

As a company, Shenzhou Tike Metal Co., Ltd. emphasizes sustainability and environmental responsibility. Their products are designed to be recyclable and reusable, aligning with global initiatives to reduce waste and promote eco-friendly practices. This commitment to sustainability is reflected in their production processes and product design, ensuring that their offerings are not only functional but also environmentally conscious.

The Sheet Plate Punching Mesh from Shenzhou Tike Metal Co., Ltd. represents a versatile and durable solution for a wide range of applications. Its combination of high opening rate, lightweight design, corrosion resistance, and customizable options makes it an ideal choice for both industrial and architectural projects. As industries continue to prioritize efficiency, sustainability, and aesthetics, the demand for such advanced metal mesh solutions is expected to grow.

For more information about the Sheet Plate Punching Mesh and other products offered by Shenzhou Tike Metal Co., Ltd., visit their official website at https://www.tikemetal.com/.

Source: National Institute of Standards and Technology (NIST). https://www.nist.gov/

For further information on material standards and testing procedures, refer to NIST's publications on standards and measurements.

RELATED PRODUCTS