In the world of industrial infrastructure, structural integrity and long-term durability are not just requirements; they are fundamental pillars of safety and operational efficiency. This comprehensive guide delves into Hot Dipped Galvanized Grating, the unparalleled solution for demanding environments. We will explore everything from market trends and core technical specifications to advanced manufacturing processes and real-world case studies, establishing why this material is the gold standard for projects across the globe.

The global industrial grating market is on a significant upward trajectory, projected to grow at a CAGR of over 4.5% in the coming years. This growth is fueled by massive investments in infrastructure development, renewable energy projects (like wind and solar farms), and the modernization of manufacturing and processing plants. Within this market, Hot Dipped Galvanized Grating commands a dominant share due to its superior corrosion resistance and exceptional strength-to-weight ratio. According to industry reports, materials with enhanced anti-corrosion properties are seeing a 15% higher adoption rate in coastal and chemically aggressive environments compared to untreated or painted alternatives, underscoring a clear market shift towards long-term, low-maintenance solutions.

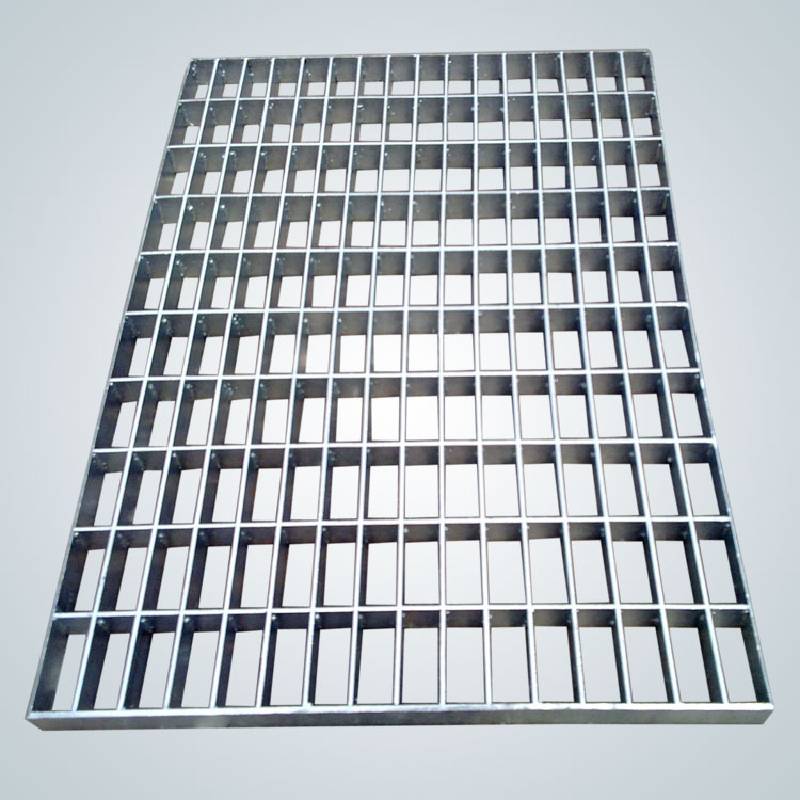

Selecting the correct grating requires a professional understanding of its technical parameters. These specifications directly impact load-bearing capacity, safety, durability, and cost-effectiveness. Tike Metal provides a wide range of options that conform to international standards like ANSI/NAAMM MBG 531.

| Parameter | Standard Specification | Technical Significance & Impact |

|---|---|---|

| Bearing Bar Size | 25x3mm to 75x10mm | The primary load-bearing component. Height and thickness determine the grating's strength and deflection resistance. Larger bars support heavier loads over longer spans. |

| Bearing Bar Pitch | 30mm, 40mm, 60mm | The center-to-center distance between bearing bars. A smaller pitch (e.g., 30mm) offers higher strength and a safer walking surface, preventing small objects from falling through. |

| Cross Bar Pitch | 50mm, 100mm | The distance between cross bars. This parameter primarily ensures the alignment and stability of the bearing bars. A 100mm pitch is standard for most industrial applications. |

| Material Grade | ASTM A36 / Q235B / S275JR | Defines the steel's chemical composition and mechanical properties (yield strength, tensile strength). Q235B is a robust, low-carbon steel ideal for welding and galvanizing. |

| Surface Type | Plain / Serrated | Plain surfaces are standard for most walkways. Serrated (toothed) surfaces provide superior slip resistance, crucial for oily, wet, or inclined areas. |

| Galvanization Standard | ASTM A123 / EN ISO 1461 | Specifies the requirements for the hot-dip galvanizing process, ensuring a minimum zinc coating thickness (typically 85-100 microns) for optimal corrosion protection. |

The performance of a Hot Dipped Galvanized Grating is directly tied to its manufacturing process. At Tike Metal, we adhere to a stringent, multi-stage quality control protocol that guarantees a product of superior quality. Our process combines high-precision machinery with meticulous craftsmanship.

High-grade Q235B steel is precision-cut and assembled. Bearing and cross bars are joined using high-amperage pressure resistance welding, forming a monolithic panel.

The fabricated grating undergoes degreasing, rinsing, and then acid pickling to remove all mill scale, rust, and impurities, creating a chemically clean surface.

The grating is immersed in a molten zinc bath at ~450°C (840°F). A metallurgical reaction occurs, forming layers of zinc-iron alloy, bonded permanently to the steel.

The grating is cooled, and excess zinc is removed. Each panel is inspected for coating thickness (as per ASTM A123), adhesion, and visual defects before shipment.

Choosing Hot Dipped Galvanized Grating is an investment in long-term performance and safety. Here are the core advantages that set it apart.

The hot-dip galvanizing process creates a complete, tough, and metallurgically bonded zinc coating that protects the steel from corrosive elements. This results in a service life that can exceed 50 years in mild environments and 20-25 years in severe industrial or coastal settings, far surpassing paint or electroplating.

Steel grating provides one of the highest strength-to-weight ratios of any flooring material. It can handle heavy loads, such as vehicular traffic or heavy machinery, while remaining relatively lightweight for easier installation and reduced structural support requirements.

The open grid design allows for the passage of light, air, and liquids, preventing the buildup of hazardous substances. For maximum safety in slippery conditions, our serrated Hot Dipped Galvanized Grating provides exceptional anti-slip properties.

While the initial investment might be higher than painted steel, the long, maintenance-free service life results in a significantly lower total lifecycle cost. There's no need for periodic repainting or corrosion treatment, saving on labor and material costs over decades.

Numbers and data provide undeniable proof of performance. We've compiled key data to help you understand the tangible benefits of our products.

With over 15 years of dedicated experience in metal fabrication, Tike Metal stands as a beacon of authority and trust in the industry. Our commitment goes beyond simply supplying a product; we provide comprehensive solutions.

We recognize that no two projects are alike. Our engineering team works closely with clients to develop fully customized Hot Dipped Galvanized Grating solutions.

Our customization process includes:

Challenge: A client required flooring for a new offshore platform in the North Sea, an environment characterized by extreme salinity, high humidity, and constant exposure to corrosive sea spray. The material needed to be exceptionally durable and provide maximum slip resistance for worker safety.

Solution: We supplied over 5,000 square meters of serrated Hot Dipped Galvanized Grating with a heavy-duty bearing bar (50x5mm) and an enhanced zinc coating thickness of 120 microns, exceeding ASTM A123 standards.

Outcome: After 5 years in service, the grating shows no signs of corrosion. The client reported a 40% reduction in slip-related incidents compared to their previous platform, which used checker plate. The open grid design also improved safety by preventing fluid accumulation.

Challenge: A major metropolitan area was upgrading its wastewater treatment facility. They needed walkways and platform flooring that could withstand constant exposure to moisture, hydrogen sulfide (H₂S), and other corrosive chemicals.

Solution: Tike Metal provided custom-fabricated Hot Dipped Galvanized Grating panels with a 30mm bearing bar pitch for added safety. All panels were manufactured to precise dimensions based on the plant's complex layout of tanks and pipes.

Outcome: The grating has been instrumental in creating a safe, durable, and low-maintenance operational environment. The plant manager praised the solution for its long-term cost-effectiveness, eliminating the bi-annual painting schedule required by their old system.

The primary difference is the surface of the bearing bars. Plain surface grating has flat, smooth bearing bars and is suitable for most general-purpose walkways. Serrated surface grating features a series of notches or "teeth" on the top of the bearing bars. This serrated profile significantly increases the coefficient of friction, providing superior slip resistance. It is highly recommended for environments where oil, water, ice, or other slippery substances are present, or for inclined ramps.

Based on the galvanizing standards we adhere to (ASTM A123), which ensures a thick, robust zinc coating, our Hot Dipped Galvanized Grating is expected to have a service life of 20 to 25 years even in highly corrosive coastal or marine environments (classified as ISO 12944 C4 or C5-M). The zinc coating provides both barrier and cathodic protection to the underlying steel, sacrificing itself slowly over decades to prevent rust.

Our standard and most commonly used material is high-quality low-carbon structural steel, equivalent to grades such as ASTM A36, JIS G3101 SS400, or EN 10025 S275JR. These grades are chosen for their excellent combination of strength, ductility, and superior weldability, making them ideal for fabricating strong, reliable grating panels that perform exceptionally well during the hot-dip galvanizing process.

To specify the correct load capacity, you need to consider three factors: 1) the magnitude of the load (e.g., pedestrian traffic, light vehicle, heavy forklift), 2) the type of load (uniform vs. concentrated point load), and 3) the span (the unsupported distance the grating must cross). Our technical team can assist you. You can provide your project's requirements, and we will recommend the appropriate bearing bar size and pitch using standardized load tables (like those from NAAMM) to ensure safety and compliance.

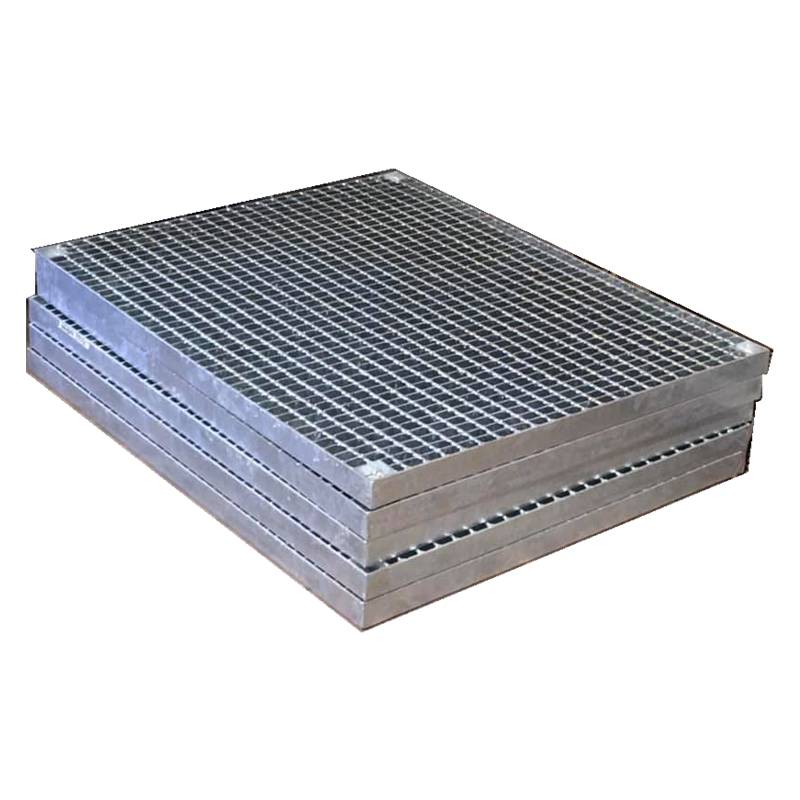

Our standard manufactured panels typically come in sizes of 1m x 6m or 1m x 5.8m to optimize container111 loading for shipping. However, one of our core strengths is customization. We can fabricate Hot Dipped Galvanized Grating to any required size, shape, or with specific cut-outs to fit around structural elements, pipes, or machinery. Simply provide us with your engineering drawings, and we will produce panels to your exact specifications.

Absolutely. Our hot-dip galvanizing process strictly conforms to ASTM A123/A123M, the standard specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. This ensures a consistent, high-quality finish. Depending on the thickness of the steel, the typical minimum average coating thickness is between 85 and 100 microns (µm), providing exceptional, long-lasting corrosion protection.

There are two primary installation methods. 1) Welding: For permanent installations, the grating can be welded directly to the supporting structure. We recommend a 3mm fillet weld at least 20mm long at the corners. 2) Clips: For applications requiring removable panels, we provide specialized saddle clips. These clips fasten the grating securely to the support beam flange without any welding, allowing for easy removal for maintenance access. We recommend at least four clips per panel.

In conclusion, Hot Dipped Galvanized Grating represents the pinnacle of industrial flooring and platform technology. Its unparalleled combination of durability, safety, low lifecycle cost, and design flexibility makes it the superior choice for any project where performance cannot be compromised. By partnering with an experienced and certified manufacturer like Tike Metal, you secure not just a product, but a reliable, long-term solution backed by expertise and a commitment to quality.

For further reading and verification of the standards and principles discussed:

RELATED PRODUCTS