I’ve walked more catwalks and pump halls than I care to admit, and—honestly—steel grating that survives rain, oil mist, and foot traffic without fuss is worth its weight in zinc. Demand is up again, driven by tighter safety rules and aggressive maintenance cycles. In short, Hot Dipped Galvanized Grating is having a moment, and not by accident.

Contractors want three things: predictable lead times, compliant slip resistance, and coatings that don’t flake. Utilities and food processors, in particular, are switching from painted steel to Hot Dipped Galvanized Grating for longer intervals between shutdowns. Sustainability teams also like the recyclability angle and the comparatively low lifetime maintenance cost.

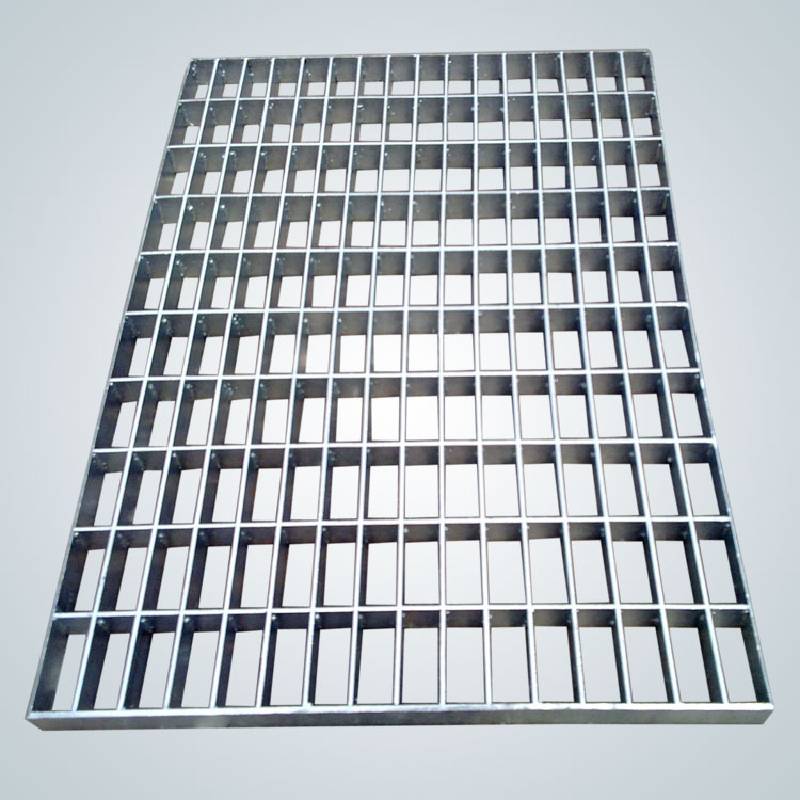

Materials: low-carbon steel (e.g., Q235/ASTM A36) bearing bars and twisted cross bars. Welding: resistance/pressure welding for solid load transfer. Then the hot-dip: pickling, fluxing, immersion in molten zinc, quench—done per ASTM A123 or ISO 1461. Typical zinc thickness ≈70–100 μm for industrial duty [1][2]. Service life? Around 15–30 years in C3–C4 atmospheres, per ISO 12944 guidance, with sensible maintenance [3].

| Bearing bar size | 25×3 mm to 50×5 mm (others on request) |

| Bar pitch | 30–40 mm typical |

| Cross bar | Twisted square 6 mm (≈50–100 mm pitch) |

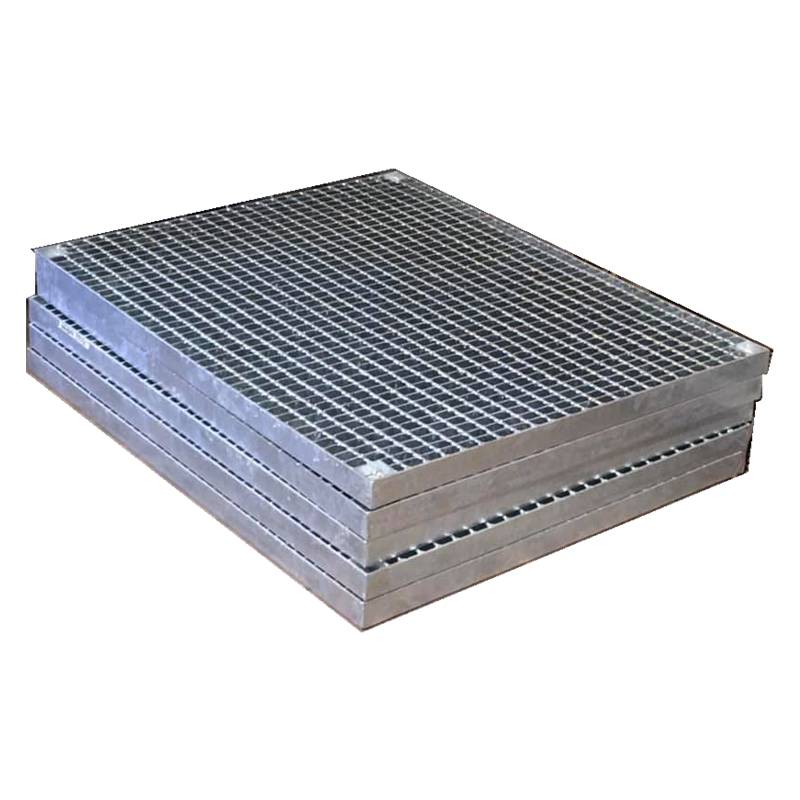

| Panel size | Up to ≈1000×6000 mm (cut-to-fit available) |

| Surface | Hot Dipped Galvanized Grating finish; serrated or plain bars |

| Coating thickness | ≈70–100 μm per ASTM A123 / ISO 1461 (real-world use may vary) |

| Testing | Magnetic gauge for thickness (ISO 2178), visual per [1][2]; salt spray per ASTM B117 for R&D [4] |

Installer feedback has been consistent: panels lay flat, clip systems are straightforward, and serrated bars add welcome bite when it’s wet. To be honest, that last bit is what keeps incident reports down.

Corrosion resistance, load-to-weight efficiency, non-combustibility, and honest-to-goodness drainage. Plus, Hot Dipped Galvanized Grating is easier to keep hygienic than checker plate in splash zones.

Options include plain/serrated/I-bar bearing bars, banding, toe plates, cutouts around pipework, galvanizing mass control, and prefit clips. Origin: East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui City, Hebei Province.

| Vendor | Certs/Standards | Lead time | Notes |

|---|---|---|---|

| Tikemetal (factory, Hebei) | ISO 9001; ASTM A123 / ISO 1461 alignment | ≈10–20 days | Strong QC, custom cutouts, fair MOQ |

| Import broker | Varies by lot | ≈25–45 days | Pricey freight; specs can drift |

| Local fabricator | Often ISO; galvanizing via third party | ≈7–30 days | Good for rush repairs; higher unit cost |

Coastal wastewater lift station retrofit: 620 panels of Hot Dipped Galvanized Grating, serrated 30×5 mm bars. After 24 months, field gauges showed coating thickness at ≈82 μm median with no red rust in high-splash zones. Lab salt-spray (ASTM B117) on sister samples passed 500 h without red rust; real plants are messier, but the trend matches expectations [4].

If you need quick submittals, ask for mill certs, galvanizing bath records, and a loading table matched to your span. Sounds fussy, but it saves rework later.

RELATED PRODUCTS