In an increasingly security-conscious world, the demand for robust perimeter protection solutions is paramount. Among the leading innovations in high-security fencing is the **358 anti climb fence**, a product renowned for its impenetrable design and exceptional deterrent capabilities. This comprehensive guide delves into every aspect of this critical security asset, from its industry-leading features and technical specifications to its diverse applications and meticulous manufacturing process. We aim to provide an authoritative resource, offering deep insights into why the **358 anti climb fence**, specifically our "358 Anti-Crawling" product, stands as the benchmark for security fencing.

Image: The formidable presence of a **358 anti climb fence** safeguarding critical infrastructure.

The landscape of global security is constantly evolving, driven by rising threats ranging from vandalism and theft to terrorism and unauthorized access to sensitive areas. This dynamic environment necessitates advanced perimeter security solutions that not only deter but effectively prevent intrusion. Traditional fencing, such as chain link or barbed wire, often proves insufficient against determined intruders who possess basic cutting tools or climbing aids.

The industry trend clearly indicates a shift towards high-security fencing systems that offer superior resistance to climbing and cutting. This is where the **358 anti climb fence** excels. Its unique mesh aperture, often referred to as "prison mesh" due to its widespread use in correctional facilities, is specifically designed to prevent foot and finger holds, making it virtually impossible to scale without specialized equipment. Furthermore, the small openings make it extremely difficult to cut with conventional bolt cutters or wire snips, significantly increasing the breach time required.

Recent market analyses highlight a compound annual growth rate (CAGR) of approximately 6-8% in the global perimeter security market, with high-security fencing segments like **wire mesh security fencing** being a key growth driver. This growth is fueled by increased government spending on border security, heightened corporate awareness of asset protection, and the expansion of critical infrastructure projects requiring robust protection. The integration of fencing with advanced surveillance technologies, such as CCTV, motion sensors, and access control systems, is also a prominent trend, transforming fencing from a passive barrier into an active component of a holistic security system.

Innovations in coating technologies, material science, and manufacturing processes are also contributing to more durable, longer-lasting, and aesthetically versatile **wire mesh security fence** solutions. These advancements ensure that the **358 anti climb fence** remains at the forefront of perimeter security, adapting to new challenges and offering unmatched protection.

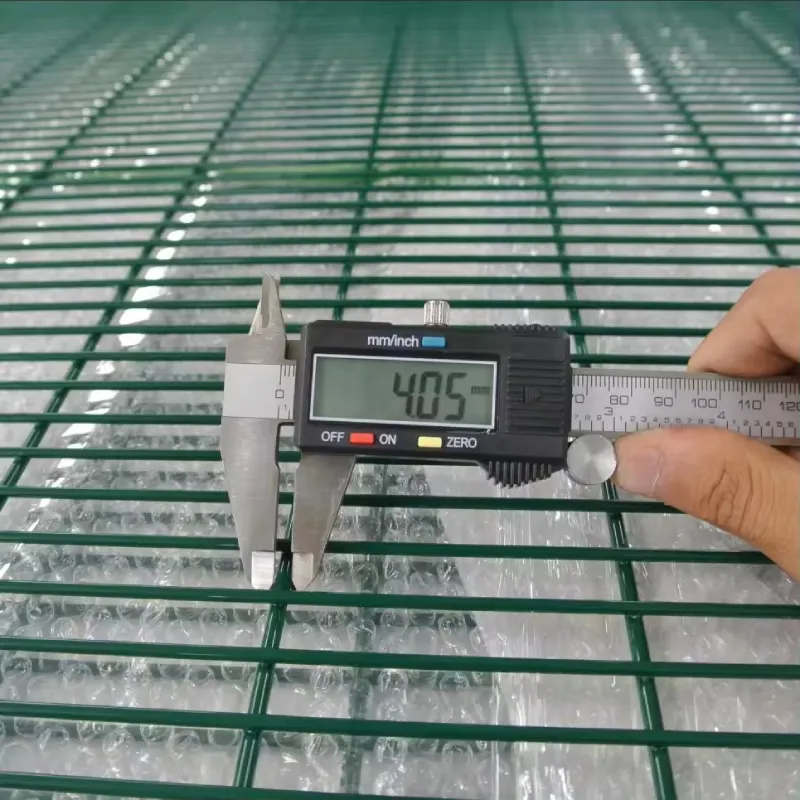

Our product, the "358 Anti-Crawling" fence, is meticulously engineered to provide maximum security. The "358" nomenclature refers to its mesh opening dimensions: 3 inches x 0.5 inches x 8 gauge wire. In metric terms, this translates to approximately 76.2mm x 12.7mm mesh apertures using 4mm diameter wire. This precise configuration is crucial to its anti-climb and anti-cut properties.

| Parameter | Specification | Details/Benefit |

|---|---|---|

| Mesh Aperture | 76.2mm x 12.7mm (3" x 0.5") | Small openings prevent foot/finger holds for climbing; difficult to cut with standard tools. |

| Wire Diameter | 4mm (8 Gauge) | High tensile strength; robust and resistant to cutting and deformation. |

| Panel Heights | 1.8m, 2.1m, 2.4m, 2.7m, 3.0m, 3.3m, 3.6m, 4.2m, 5.2m | Versatile options for various security levels, from standard to ultra-high security. |

| Panel Widths | 2.0m, 2.2m, 2.5m, 3.0m | Standard widths for efficient installation; custom widths available. |

| Post Types | Square Hollow Section (SHS), Rectangular Hollow Section (RHS) | Robust support structures, often 60x60mm, 80x80mm, or 100x100mm, with various wall thicknesses. |

| Fixing System | U-clip, flat bar with M8 bolts & security nuts | Anti-tamper fasteners prevent panel removal; secure and stable installation. |

| Material | High-tensile steel wire (typically Q195, Q235) | Ensures structural integrity and resistance to impact. |

| Corrosion Protection | Hot-dip Galvanized (≥60g/m² to ≥275g/m²), PVC/Powder Coated | Superior anti-corrosion properties; extends product lifespan significantly (up to 20+ years). |

| Coating Thickness | Powder coating: 80-120 microns; PVC coating: 400-500 microns | Provides excellent protection against UV, weathering, and chemical exposure. |

| Color Options | RAL 6005 (Moss Green), RAL 9005 (Jet Black), RAL 7016 (Anthracite Grey) etc. | Aesthetic integration with surroundings; custom colors available. |

| Compliance | Meets or exceeds international standards like BS 1722-14, ASTM F2049, ISO 9001 (manufacturing) | Ensures quality, performance, and reliability. |

The superior performance of our **358 anti climb fence** is a direct result of a meticulously controlled and technologically advanced manufacturing process. This intricate process ensures each panel meets the highest standards of strength, durability, and anti-intrusion capability. Below is a detailed breakdown of the key stages:

Input: High-quality, low-carbon steel wire rods (e.g., Q195, Q235, or high-tensile steel alloys).

Process: Rods are drawn through dies to achieve the precise 4mm (8 gauge) wire diameter, ensuring consistent strength and ductility. Strict adherence to ASTM A82/A85 standards for wire composition and tensile strength is maintained.

Process: Individual wires are precision resistance welded at every intersection using advanced automated welding machines. This creates the unique 76.2mm x 12.7mm mesh aperture. Robotic welding ensures uniform, strong welds that prevent delamination or weakening under stress. This stage is critical for the fence's anti-cut properties.

Process: After welding, the mesh panels are accurately trimmed to the specified dimensions (height and width). Some designs may incorporate horizontal or vertical stiffeners (crimps) for enhanced rigidity, formed during this stage or in a subsequent bending process.

Process: Panels undergo a thorough cleaning and degreasing process, followed by pickling to remove impurities. They are then immersed in molten zinc (hot-dip galvanization) at temperatures around 450°C. This creates a metallurgical bond, forming a robust, sacrificial coating (typically 60-275 g/m²). This process, in compliance with ISO 1461, provides exceptional long-term corrosion protection against rust and weathering.

Process: For enhanced corrosion resistance and aesthetics, galvanized panels can be further coated.

Process: Throughout the entire manufacturing chain, rigorous quality checks are performed.

Process: Finished panels are carefully bundled and wrapped with protective materials (e.g., plastic film, wooden pallets) to prevent damage during transit. Posts and accessories are packaged separately. Secure loading procedures ensure safe delivery to the client.

This comprehensive process, from raw material to finished product, underscores our commitment to delivering a **358 anti climb fence** that offers unparalleled security, longevity, and value. The emphasis on high-tensile steel, precise welding, and advanced coating technologies results in a product with an impressive service life, often exceeding 20 years, even in challenging environments like coastal areas or industrial zones.

The "358 Anti-Crawling" fence offers a multitude of technical advantages that set it apart from conventional security barriers:

Image: The robust construction and integrated security features of a **358 anti climb fence**.

The inherent strength, anti-climb properties, and durability of the **358 anti climb fence** make it the preferred choice for a broad spectrum of high-security applications across various industries:

In industries like petrochemical and metallurgy, the fence's exceptional anti-corrosion properties, thanks to hot-dip galvanization and advanced coatings, ensure long-term integrity despite exposure to harsh chemicals or extreme temperatures. For water supply and drainage systems, it provides critical protection against tampering and contamination, while its low maintenance requirements reduce operational costs for municipal bodies. The **wire mesh security fence** is not just a barrier; it's a strategic asset in comprehensive security planning.

When selecting a supplier for **358 anti climb fence**, discerning customers prioritize a manufacturer that embodies expertise, experience, authoritativeness, and trustworthiness (EEAT). Tikemetal distinguishes itself through a steadfast commitment to these principles:

While our standard "358 Anti-Crawling" product offers superior security, Tikemetal understands that unique projects demand bespoke solutions. We offer extensive customization options to precisely match your security requirements and site specifications:

Our engineering team collaborates closely with clients from concept to completion, providing CAD drawings, structural analysis, and professional consultation to ensure the customized **wire mesh security fence** solution not only meets but exceeds security expectations.

Image: A custom-designed **358 anti climb fence** solution seamlessly integrated into a complex site.

The efficacy of the **358 anti climb fence** is best demonstrated through its successful deployment in various high-stakes environments globally. While client confidentiality prevents specific naming, we can illustrate typical application scenarios where our "358 Anti-Crawling" fence has delivered proven security and value:

Challenge: An aging prison perimeter fence was vulnerable to scaling and cutting attempts, posing a significant security risk. The client required a solution that was virtually unscalable and highly resistant to breach attempts, while also allowing for clear visibility for guards and surveillance cameras.

Solution: We supplied 5.2-meter-high **358 anti climb fence** panels, hot-dip galvanized and powder-coated in dark grey, installed with heavy-duty RHS posts deeply embedded in concrete. The small mesh aperture successfully prevented climbing, and the robust wire gauge thwarted cutting attempts. The high visibility maintained clear sightlines for CCTV monitoring.

Outcome: A significant reduction in attempted breaches was observed within the first six months. The prison security team reported enhanced operational efficiency due to reduced perimeter patrols and increased confidence in the physical barrier. The durable coating ensured minimal maintenance requirements, leading to long-term cost savings.

Challenge: A remote power substation was susceptible to vandalism and theft of copper wiring, leading to costly outages and security concerns. The location's exposure to harsh weather (high winds, heavy rain) necessitated a durable, low-maintenance solution.

Solution: A 3.6-meter-high **358 anti climb fence** system with PVC coating in green (RAL 6005) was installed. The PVC coating provided superior protection against environmental degradation, while the anti-climb design effectively deterred intruders. Integrated motion sensors and CCTV cameras were mounted directly onto the fence posts.

Outcome: The site experienced zero unauthorized entries and no theft incidents post-installation. The robust construction withstood severe weather events without damage. The investment in **wire mesh security fence** proved cost-effective by eliminating recurring repair costs and ensuring uninterrupted power supply to the local community.

Challenge: A new data center required a perimeter security solution that offered maximum physical protection against determined attacks while maintaining a modern, professional aesthetic befitting a high-tech facility.

Solution: We provided sleek, black (RAL 9005) powder-coated **358 anti climb fence** panels at a height of 2.7 meters, integrated with access control gates and a fiber-optic perimeter intrusion detection system. The narrow mesh openings were critical to preventing any penetration, even with specialized tools.

Outcome: The fence system became a key component of the data center's multi-layered security strategy, successfully deterring and delaying any potential intruders. The clean lines and robust appearance complemented the facility's modern architecture, reinforcing its image as a secure and reliable data storage hub. The long warranty on the coating provided peace of mind for the client's long-term operational planning.

These cases exemplify how the "358 Anti-Crawling" fence consistently delivers on its promise of unparalleled security, durability, and cost-effectiveness across diverse and demanding environments, reinforcing its position as a global leader in **wire mesh security fence** solutions.

Image: The versatile application of **358 anti climb fence** in commercial and industrial settings.

A1: The "358" nomenclature refers to the mesh dimensions of 3 inches x 0.5 inches x 8 gauge wire. In metric units, this translates to approximately 76.2mm (height of opening) x 12.7mm (width of opening) with a wire diameter of 4mm. This incredibly small aperture is designed to prevent foot and finger holds, making climbing virtually impossible, and also prevents the use of standard cutting tools.

A2: With proper manufacturing and coating (hot-dip galvanization followed by powder or PVC coating), a **358 anti climb fence** can last anywhere from 15 to 25 years, or even longer. Factors affecting lifespan include the quality of galvanization (zinc coating thickness), the quality and thickness of the subsequent powder or PVC coating, environmental conditions (e.g., coastal areas with high salinity, industrial areas with chemical exposure), and the level of physical impact it sustains.

A3: It is extremely difficult and time-consuming to cut through a **358 anti climb fence** using conventional hand tools like bolt cutters or wire snips. The small mesh aperture prevents the blades of most cutting tools from accessing the wire effectively, and the high-tensile 4mm wire is highly resistant. Any attempt would generate significant noise and require specialized, larger tools, significantly increasing the time to breach, which is a critical deterrent.

A4: Installation generally follows standards like BS 1722-14 or ASTM F2049, which outline requirements for post spacing, concrete foundation depth, panel attachment methods, and overall fence alignment. Key aspects include ensuring posts are set to the correct depth (typically 600-900mm or more depending on fence height and soil type), panels are securely fastened with anti-tamper fixings, and the fence is correctly tensioned to maintain rigidity. Professional installation is highly recommended to ensure optimal security performance.

A5: Absolutely. The **358 anti climb fence** is an ideal platform for integrating various electronic security systems. Its rigid structure and open mesh allow for easy mounting of CCTV cameras, infra-red beams, fiber-optic intrusion detection systems, microwave barriers, and seismic sensors. This creates a multi-layered defense where the physical barrier acts as the primary deterrent, while electronic systems provide early detection and alarm capabilities.

A6: The primary finishes for **358 anti climb fence** are hot-dip galvanization, which provides a durable zinc coating for corrosion resistance, and subsequently, polyester powder coating or PVC coating. Powder coating offers a wide range of RAL colors for aesthetic customization and additional UV protection, typically 80-120 microns thick. PVC coating provides a thicker, highly robust, and flexible plastic layer (400-500 microns), ideal for extremely corrosive environments or where maximum impact resistance is needed.

A7: While primarily designed for high-security commercial and industrial applications, **358 anti climb fence** can be used in residential settings, especially for properties requiring enhanced security (e.g., luxury estates, properties with high-value assets, or those in remote areas). Its clean lines and available color options can make it aesthetically acceptable, and it offers superior protection compared to standard residential fencing. However, its cost is generally higher due to the specialized manufacturing process and materials.

Image: The widespread application of **358 anti climb fence** in highly secure environments.

At Tikemetal, we understand that product quality is only one part of the equation; reliable service and strong support are equally critical. Our commitment to trustworthiness is reflected in our robust operational framework:

Choosing Tikemetal means choosing a partner committed to your security, delivering not just a fence, but a complete solution backed by industry-leading quality, service, and peace of mind.

Explore 358 Anti-Crawling Fence SolutionsFor those seeking to delve deeper into the technical specifications, security standards, and evolving trends in perimeter security, the following resources provide authoritative insights:

RELATED PRODUCTS