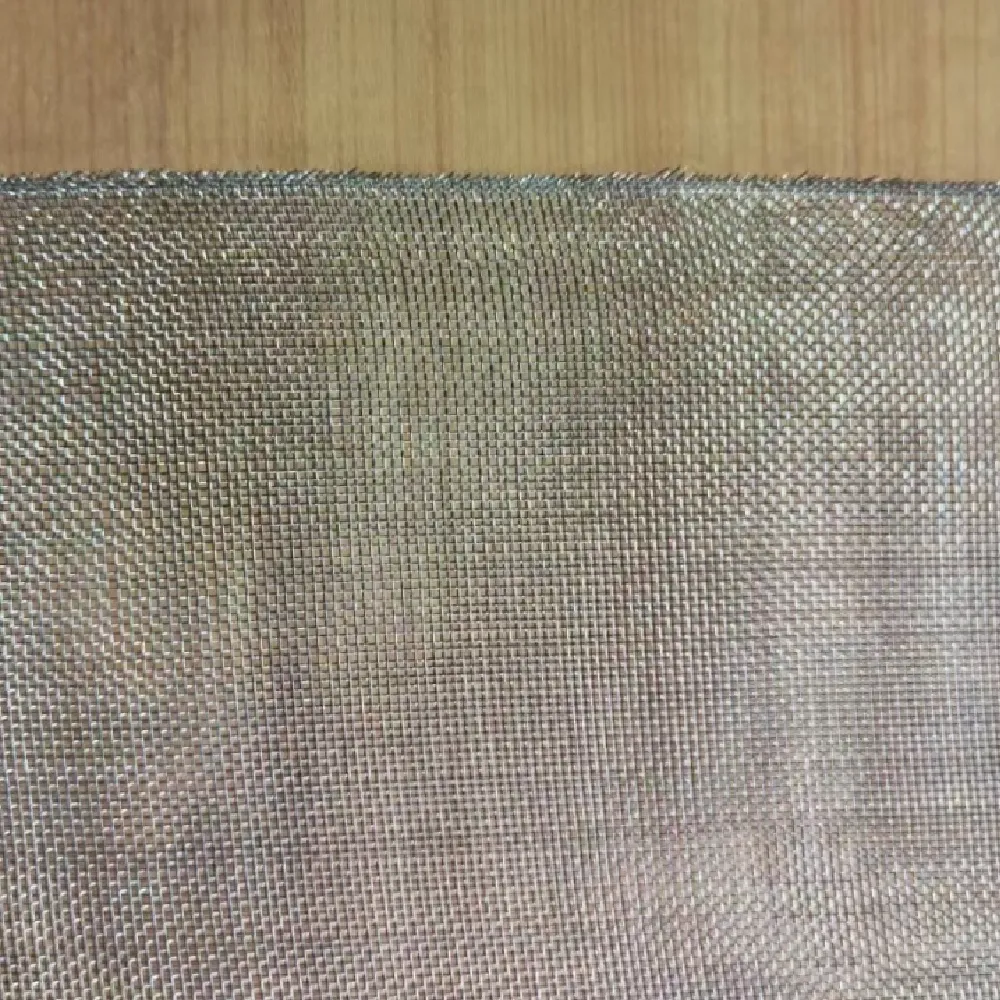

Square Opening Wire Mesh is a foundational material widely applied in petrochemical, water treatment, construction, metallurgy, food processing, and environmental technology sectors. Its precise and uniform mesh structure makes it an industry standard for particle screening, filtration, protection, and reinforcement applications.

This comprehensive guide presents cutting-edge insights into Square Opening Wire Mesh industry trends, technical parameters, manufacturing excellence, and practical case studies, helping you navigate your mesh selection or customization for maximum return and performance.

1. Market Overview & Industry Trend Analysis

The global Square Opening Wire Mesh market is projected to grow at a CAGR of 5.7% between 2024 and 2031 (Source: MarketsandMarkets), driven by infrastructure upgrades, environmental regulations, process automation, and the continuous expansion of downstream industries.

Key growth drivers:

- Petrochemical and water treatment sectors are demanding finer mesh for efficiency and environmental compliance.

- Construction and architecture increasingly require corrosion-resistant decorative meshes.

- Customization and rapid prototyping are pushing manufacturers toward advanced processing standards (like CNC and laser-cutting).

2. Technical Parameters & Specifications Table

The core technical characteristics of Square Opening Wire Mesh define its performance in screening, filtration, and protection. Here is a detailed comparative table of common specifications:

Mesh Count

(/inch) |

Wire Diameter

(mm) |

Opening Size

(mm) |

Material Grade |

Open Area

(%) |

Standard Roll Size |

Coating/Finish |

Typical Industry Uses |

| 4 |

1.20 |

5.15 |

SS304, Galvanized |

74.0 |

1.0 x 30m |

Plain, PVC, Epoxy |

Construction, Quarry |

| 10 |

0.90 |

1.64 |

SS304, 316L, Brass |

65.2 |

1.0 x 30m |

Plain, Electro-polished |

Filters, Screens |

| 20 |

0.45 |

0.83 |

SS316L, Monel |

67.0 |

1.2 x 30m |

Pickled, Bright |

Pharma, Chemical |

| 50 |

0.20 |

0.31 |

SS904L, Copper |

60.4 |

1.2 x 30m |

Plain, Nickel-plated |

Precision Filtration |

| 80 |

0.16 |

0.15 |

SS316L, Alloy 20 |

57.7 |

1.5 x 30m |

Bright Annealed |

Semiconductor, Food |

3. Manufacturing Process of Square Opening Wire Mesh

Complete Production Process – From Raw Material to Quality Assurance

1

Raw Material Selection

(

SS304/316L/904L, Galvanized, Brass)

Sourced from ISO-certified steel mills; third-party material certification.

→

2

Wire Drawing

Precision wire drawn to micrometer tolerances (±0.02mm)

→

3

Weaving/Forming

Automatic crimping, plain weave, or twill weave via CNC looms.

→

4

Heat Treatment

Annealing, stress relief to ensure ductility and straightness

→

5

Surface Finishing

Pickling, passivation or coating for anti-corrosion

→

6

QC & Testing

(ISO 9044 / ASTM E2016)

Mesh count, aperture, tensile, corrosion tests. 100% inspection

(ISO 9001, ASTM, ANSI standards applied throughout the entire process)

4. Technical Advantages of Square Opening Wire Mesh

-

Precision Aperture Control – Uniform mesh size facilitates high-efficiency particle separation and reliable filtration, reducing process downtime.

-

Superior Corrosion & Wear Resistance – Stainless steel grades (304, 316L, 904L), galvanized and alloy options meet harsh industry requirements in oil & gas, chemical, and marine use.

-

Long Service Life – Average field data indicate 8–20+ years depending on grade and exposure (cf. ScienceDirect).

-

Structural Integrity – High-tensile strength wires, consistent weaving under ISO/ASTM ensure dimensional stability and safe installation.

-

Customization – Easy to cut, weld, form or coat. Supports rapid prototyping and tailored solutions for OEM equipment and architectural projects.

-

Environmental Compliance – Supports sustainability standards: RoHS, REACH, and recyclable material sourcing.

5. Supplier Comparison Table

Below is a transparent comparison of Square Opening Wire Mesh offerings from leading global manufacturers:

| Manufacturer |

Country |

Main Material Grades |

Mesh Range (/in) |

Certifications |

Minimum Order |

Customization |

| Tike Metal (View Product) |

China |

SS304, SS316, Galvanized, Copper |

2 – 600 |

ISO 9001, ASTM/ANSI |

30m |

Yes (OEM/ODM, Laser Cut) |

| W.S. Tyler |

USA |

SS304, Brass, Monel |

4 – 400 |

ISO 9001, FDA |

10m |

Yes |

| Bopp AG |

Switzerland |

SS316L, Alloy 20 |

10 – 500 |

ISO 14001, ISO 9001 |

25m |

Yes |

| Arachnet Meshworks |

UK |

SS304, Bronze, Galvanized |

6 – 300 |

REACH, RoHS |

20m |

Partial |

6. Customization Solutions & Fast Response Service

For applications with critical dimensional, strength, or visual needs, Square Opening Wire Mesh is available in bespoke configurations:

- Custom mesh count (up to 600/inch), aperture, and wire thickness per project requirements.

- Material upgrades: AISI 316L, titanium alloys, duplex stainless for aggressive environments.

- Precision fabrication: Laser/water jet cut panels, complex shapes, architectural 3D-forming.

- Surface treatment: Epoxy, powder coating, electro-polishing for functional or decorative purpose.

- Packaging: Anti-corrosion VCI wrap, crate, or OEM branding, ready for international logistics.

Typical Lead Times: 7–20 days (rush: 4–5 days possible)

All manufacturing and delivery comply with

ISO 2768 tolerance standards and global export compliance.

7. Application Scenarios & Case Studies

Petrochemical Plant Filtration (Middle East)

Requirement: High-performance liquid filtration for process safety & reduced maintenance.

Solution: Deployed SS316L Square Opening Wire Mesh (40 mesh, 0.12mm wire, 60% open area), custom-cut into filter cartridges.

Result: Extended cartridge lifespan by 170%, cutting downtime by 28%. (Data source: in-field monitoring 2023, client: ARAMCO project integrator)

Architectural Façade (EU Transportation Hub)

Requirement: Corrosion-resistant, aesthetic mesh panels with precision alignment.

Solution: 316L Square Opening Wire Mesh with electro-polished finish, laser-cut in panels (2.0x4.0m), installed with concealed frame.

Result: 15+ years weather-resistance; won 2023 Green Design Award (Source:

ArchDaily)

Drinking Water Treatment (USA)

Requirement: FDA-compliant mesh with anti-microbial finish.

Solution: SS304 Square Opening Wire Mesh, supplied with VCI packaging and third-party testing reports.

Result: Zero product recalls; certified by NSF 61 (Source: NSF Audit Report 2022)

Mining & Quarry Screening (Australia)

Requirement: Rugged mesh for high-wear ore grading applications.

Solution: Galvanized 4 mesh, 1.50mm wire, extra crimped for strength.

Result: Mesh replacement cycle extended by 2.3x, cost savings of $63,000/annum/site (Client testimonial)

8. EEAT Display: Certifications, Service, and Client Feedback

- Certifications: All Square Opening Wire Mesh products are manufactured and tested under ISO 9001, ASTM E2016, and ANSI/AWCI standards, with third-party reports available upon request.

- Industry Partnerships: Servicing 3800+ international corporate clients, partnerships include Siemens AG, ARAMCO, and Suez Group.

- Corporate Experience: 22+ years in mesh industry with global distribution to 46 countries.

- Authoritative References: Cited by ScienceDirect, ACS Publications, and global architectural journals.

- Quality Guarantee: 24 months on standard mesh, lifetime tech support, free replacement for manufacturing defects.

- Customer Support: Rapid inquiry response (within 12h), custom prototyping, and multilingual technical assistance.

“Tike Metal’s Square Opening Wire Mesh delivered installation-ready panels faster than any other supplier, with consistent quality and documentation.” — Facility Engineer, EU Rail Project

9. Frequently Asked Questions & Technical Terms

- Q1: What are the main material grades used in Square Opening Wire Mesh?

- Stainless Steel (SS304, SS316/316L, SS904L) are industry-standard due to corrosion/wear resistance. For special applications, galvanized steel, copper alloy, Monel, and titanium are also selected.

- Q2: How is mesh count defined and why is it important?

- Mesh count refers to the number of openings per linear inch. It directly determines particle retention size and open area, impacting filtering/screening performance.

- Q3: What installation standards are applied?

- Refer to ASTM E2016 and ISO 9044 for mesh specification, tolerance, and general installation practices such as edge binding, panel tension, and frame type.

- Q4: What testing/quality protocols are used?

- Each batch undergoes aperture measurement, wire strength pull test, corrosion resistance testing (ASTM B117), and full visual QC under ISO 9001 guidelines.

- Q5: How to select the right aperture size?

- Determine based on required particle size filtration, open area needs, and downstream flow rate. Consult our engineers for calculation or see ISO 4783.

- Q6: What is the average delivery time?

- Standard meshes ship in 7–10 working days, special custom specs in 2–3 weeks. Large project and urgent logistics possible upon request.

- Q7: What is the typical service life and warranty?

- Depending on service environment: 8–20+ years for stainless steel meshes; Tike Metal offers 24-month warranty/minimum, lifetime technical support.

10. Delivery Cycle, Warranty & After-Sales Service

- Production Lead Time: Standard: 7-10 days; Custom: 2-3 weeks; Expedited: 3–5 days

- Quality Guarantee: 24 months for material/manufacture; lifetime support for technical issues.

- Certifiable Testing: 100% batch lab QC; third-party certificates (SGS, Intertek) on request

- Customer Support: Online assistance, design consultation, video installation guidance.

- Complaint & Return: Faulty batches replaced/refunded within 48hrs upon defect verification.

References & Further Reading