Wire mesh screens are widely used in various fields such as construction, transportation, agriculture, etc. Their unique structural characteristics make them play an important role in enhancing engineering stability and extending service life. This article will explore the structural robustness and corrosion resistance of steel wire mesh, revealing its importance as a modern engineering material.

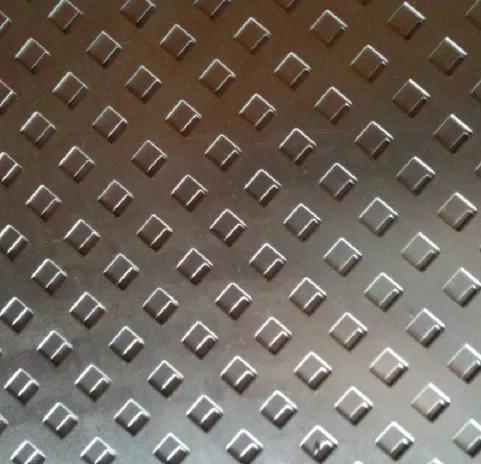

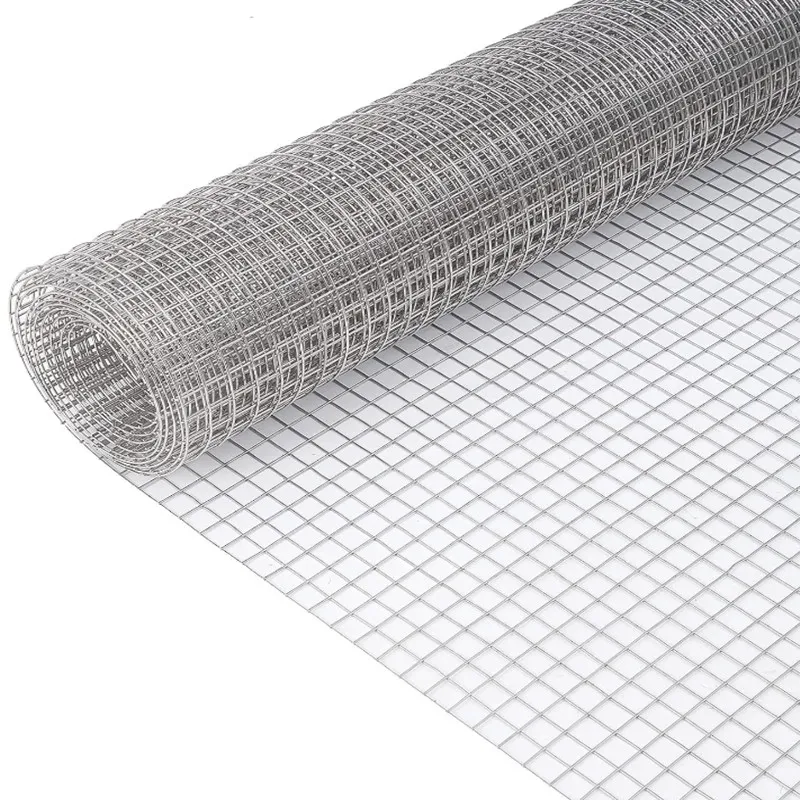

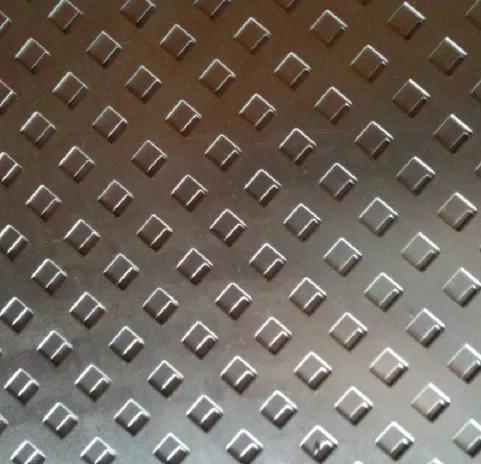

The structural robustness of wire mesh screens comes from their unique manufacturing process

The welding process firmly connects the intersecting steel wires together through high temperature, forming a sturdy overall structure. This welding process not only improves the load-bearing capacity of the components, but also effectively disperses external pressure and reduces the occurrence of stress concentration. In addition, wire mesh sheets exhibit excellent tensile and bending strength, and can withstand large external loads. Especially in construction, wire mesh screens are often used as reinforcement materials for concrete, effectively improving the compressive and crack resistance of concrete components.

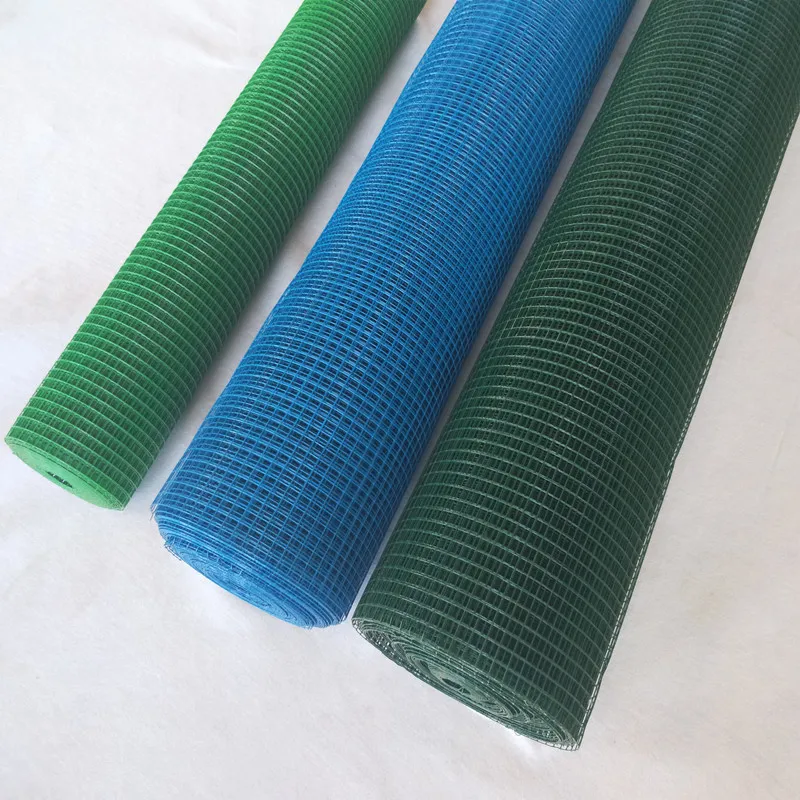

The corrosion resistance of wire mesh screens is another major advantage when used in unfavorable environments

Steel itself is prone to oxidation and corrosion, so various protective measures are usually taken during the production of steel mesh sheets, such as galvanizing, coating, and other technologies. Galvanized steel wire mesh forms a physical barrier by covering the surface of the steel wire with a layer of zinc, effectively preventing oxygen and moisture from coming into contact with the steel, thereby significantly reducing the risk of corrosion. In addition, coating technology increases the corrosion resistance of steel wire mesh by applying anti-corrosion coatings, providing guarantees for its use in various environments.

Although steel mesh panels have good structural robustness and corrosion resistance, users still need to choose and maintain them according to specific application scenarios. In long-term outdoor use, environmental factors such as acid rain, salt spray, etc. may accelerate the aging of materials, so regular inspections and necessary maintenance are key to ensuring the long-lasting use of wire mesh screens.

In summary, wire mesh screens have been widely used in various engineering and construction fields due to their excellent structural robustness and corrosion resistance. Through reasonable design and maintenance, wire mesh screens can not only effectively improve the safety and reliability of engineering, but also demonstrate long-lasting performance in harsh environments. Therefore, wire mesh screen, as an important engineering material, will continue to play an indispensable role in future development.