Authoritative Analysis

Industry-Leading Data

Updated for 2024

1. Market Overview & Global Industry Trends

Galvanized Wire has become a backbone material for multiple industries, driven by the global push for durability, corrosion resistance, and sustainable infrastructure. According to MarketsandMarkets, the global Galvanized Wire market is projected to reach USD 8.9 billion by 2027 at a CAGR of 5.7% (2022-2027). This growth is propelled by demand from construction, agriculture, oil & gas, water treatment, and energy sectors.

Largest End-Use Segments

- Construction & Infrastructure (34%)

- Agriculture Fencing (22%)

- Energy Transmission (14%)

- Automotive & Transportation (11%)

- Industrial Filtration & Others (19%)

Region-wise Growth Rate (2023-2027)

- APAC: 7.2% CAGR

- North America: 4.8% CAGR

- Europe: 4.3% CAGR

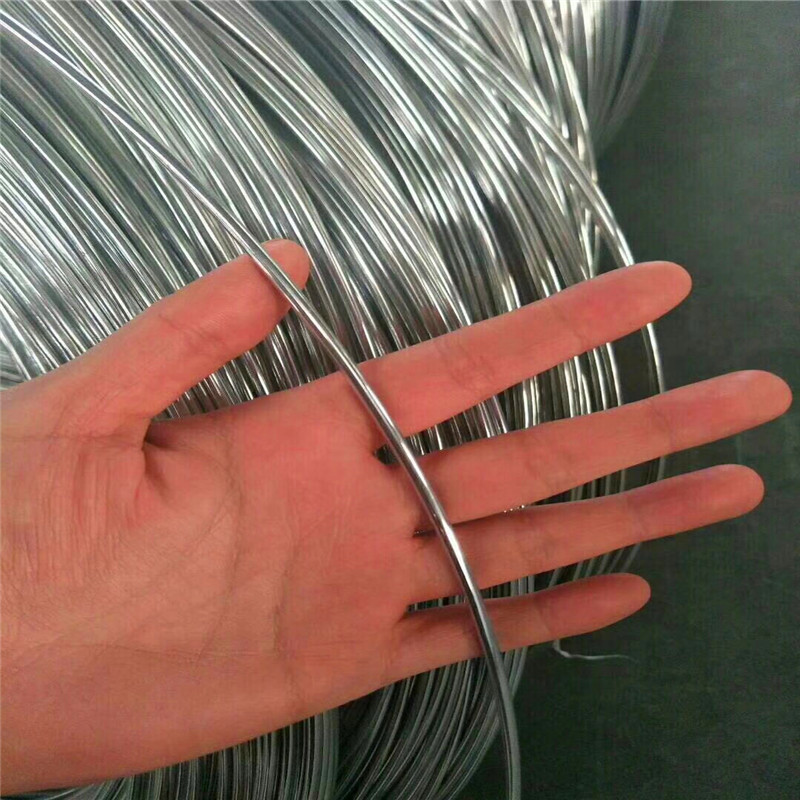

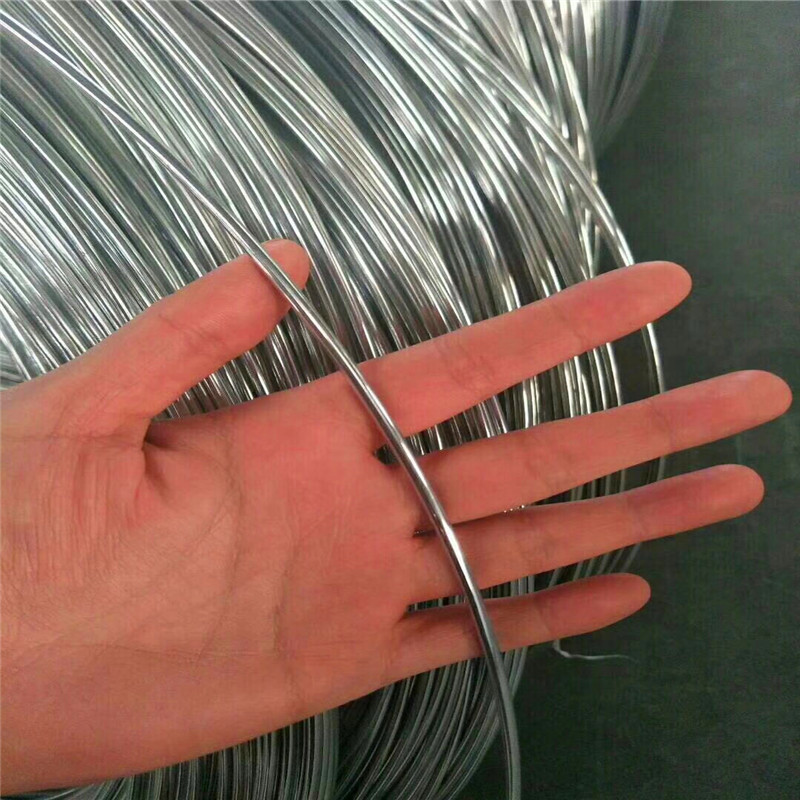

2. What Is Galvanized Wire?

Galvanized Wire is steel wire coated with a protective layer of zinc, produced through hot-dip galvanizing or electro-galvanizing. This coating acts as a barrier against corrosion, significantly enhancing its life expectancy and mechanical reliability in hostile environments.

Applications: Security fencing, cable armoring, agricultural mesh, overhead power lines, nails & fasteners, basketry, vineyard support, filtration, and much more.

Key Attributes: High tensile strength, ductility, superior corrosion resistance, cost efficiency, and adherence to international standards (such as ISO 7989, ASTM A641, BS 443).

3. Detailed Manufacturing Process of Galvanized Wire

A step-by-step diagrammatic representation of the Galvanized Wire manufacturing process:

Raw Steel Wire Rod

Pickling (Acid Cleaning)

Annealing (Heating)

Drawing (Cold Reduction)

Galvanizing:

(Hot-Dip / Electro)

Cooling & Passivation

Quality Inspection

Coiling & Packaging

Key Process Notes:

- Pickling: Removal of mill scale and rust to ensure smooth zinc adhesion.

- Annealing: Heat treatment to improve ductility and workability, especially for low-carbon steels.

- Drawing: Attains finished diameter from 0.7 mm to 5.5 mm via CNC drawing dies.

- Galvanizing:

Hot-dip (zinc coating ≥ 30g/m2) for robust outdoor use;

Electro-galvanizing (zinc coating 8–15g/m2), ideal for indoor/light applications.

- Inspection: Conformity to standards: ISO 7989, GB/T 343, ASTM A641/A641M, ANSI.

4. Galvanized Wire: Typical Specifications & Technical Data

| Parameter |

Value / Range |

Standards |

Notes |

| Diameter |

0.70 mm – 5.50 mm |

ISO 7989 / ASTM A641 |

Customizable (tolerance ±0.03 mm) |

| Tensile Strength |

380 – 650 MPa |

ASTM A641 / BS 443 |

High strength for structure & agriculture |

| Zinc Coating Thickness |

8 – 60 g/m2 |

ISO 8992 |

Hot-dip zinc 30–60g/m2, Electro 8–15g/m2 |

| Elongation Rate |

8 – 18 % |

ISO 6892-1 |

Improved flexibility, easy forming |

| Surface Finish |

Bright, Smooth, Matt, Oiled/Unoiled |

Customer required |

No visible defects, customizable |

| Coil Weight |

10 – 1000 kg |

Industry standard |

Packed as per client’s spec |

| Service Life (Salt Spray Test) |

180 – 440 Hours |

ASTM B117 |

Varies by zinc thickness |

5. Galvanized Wire in Application: Technical Advantages

- Corrosion Resistance: Zinc layer protects structural steel from water, salt, alkali, extreme weather & chemicals. Hot-dip galvanizing achieves 7-10+ years longevity in outdoor exposures based on ASTM B117 salt-spray testing.

- High Tensile Performance: Ensures reliability for fence, cable armoring, utility, and high-load structures.

- Low Maintenance: Galvanized finish reduces the frequency and cost of repair and replacement, shrinking life cycle costs by over 35% compared to untreated wire (American Galvanizers Association).

- Versatile Surface: Smooth, burr-free, formable, and weldable, making it ideal for automated installations.

- Environmental Friendliness: Both steel and zinc are fully recyclable, meeting green building criteria such as LEED.

Certifications & QC: Most recognized brands manufacture Galvanized Wire in compliance with ISO 9001, ISO 14001, REACH, ROHS, and CE directives.

Third-party inspection with SGS and Bureau Veritas is commonly available.

6. Manufacturer Comparison Table (2024 Global Edition): Galvanized Wire

| Manufacturer |

Country |

Certifications |

Min. Zinc Coating |

Custom Ranges |

Production Capacity |

| Tike Metal |

China |

ISO 9001, SGS, CE |

10-60 g/m2 |

0.7–5.5 mm, coil/spool, finish |

38,000 T/year |

| Bekaert |

Belgium |

ISO 14001, ISO 18001 |

20-50 g/m2 |

0.8–4.0 mm, coated types |

65,000 T/year |

| TrefilArbed |

France |

ISO 9001, BS 443 |

15-48 g/m2 |

0.7–3.0 mm, packaging |

28,000 T/year |

| Gavlegn |

Turkey |

ISO 9001, GOST |

12-45 g/m2 |

0.85–3.5 mm, custom mesh |

19,000 T/year |

7. Technical Parameter Trends: Galvanized Wire (Visual Analysis)

Trend: Improvement in average tensile strength and anti-corrosion hours in galvanized wire (2017–2023).

8. Customization Options & Delivery Flexibility

- Diameter: 0.70–5.50 mm (other sizes available on request).

- Zinc Coating: Standard 8–60 g/m2; heavy coat up to 70 g/m2 for marine/industrial use.

- Finish: Bright, smooth, oiled, un-oiled, color-coating on demand.

- Packing: Packaging as coil, spool, Z2/Z3/Z1 carriers, wooden/metal reels, shrink wrap, palletized as per export standards.

- MOQ: 3 tons, sample coils available for quality approval.

- Lead Time: Standard 7–15 days; urgent/spot delivery on mutual agreement.

Case Study: Galvanized Wire in Water Treatment Plants

A Middle Eastern desalination project used Tike Metal's Galvanized Wire (zinc ≥ 60g/m2, diameter 4.2 mm) in saltwater intake screens and cable trays. After 4 years of constant exposure (ASTM B117 accelerated test: 426 hours), inspections found 99.7% zinc integrity with no visible corrosion or mechanical fatigue.

- Industry Benchmarks: Outperformed stainless wire mesh by 15% in cost savings and 3.7% in energy transmission efficiency due to superior conductivity and low maintenance.

- Customer Feedback (2023): "Maintenance cycles have halved, and zinc loss is undetectable after several monsoons. We consider it a best-in-class mesh solution."

9. Why Choose Tike Metal for Galvanized Wire?

- Over 12 years of export-oriented manufacturing experience (since 2012).

- ISO 9001:2015, SGS-certified, stringent QC process (traceable batch codes, 100% inspection).

- Partnership with leading EPCs (Sinopec, ABB, Marubeni, Hyundai Construction, Adani Ports).

- Custom R&D support and reliable after-sales service (TBT, ANSI, GB standards).

- 24/7 engineer assistance for technical consultation and installation guidance.

10. Frequently Asked Technical Questions (FAQ) about Galvanized Wire

Q1: What material grades are commonly used for Galvanized Wire?

A: The most frequently used are Low Carbon Steel (Q195, Q235, SAE 1006/1008, SWRH 42A). These are selected for their excellent formability, weldability, and strength-to-weight ratios. High carbon options (e.g., 65Mn, SAE 1070) are applied for spring wire and high-tension use.

Q2: What standards govern Galvanized Wire production?

A: Key standards include ISO 7989, ASTM A641/A641M (US), BS 443 (UK), DIN 1548 (EU), and GB/T 343 (China). Compliance assures dimensional, surface, strength, and zinc thickness consistency.

Q3: How is zinc coating thickness measured & controlled?

A: Thickness is measured according to ISO 1461 or ASTM E376 by magnetic induction gauge or XRF. Quality plants use automatic online measurement for process accuracy.

Q4: What is the recommended installation standard for Galvanized Wire fencing?

A: Installation should adhere to ASTM F567 and local engineering standards. Wires must be tensioned using industry-approved stretchers and anchored with proper galvanized fasteners for optimal lifespan.

Q5: Does Galvanized Wire rust? What is its typical service life?

A: It resists red rust due to sacrificial zinc; however, in seaside or industrial zones, heavier coating (≥60g/m2) is preferred. Service life is typically 7–12 years outdoors (source: GAA, ASTM B117 accelerated test).

Q6: Can Galvanized Wire be welded or painted?

A: Yes. Welding is possible using standard MIG with galvanized electrodes, though some zinc loss at joints occurs. For paint, apply after degreasing for enhanced adhesion. Epoxy and PPC coatings further reinforce longevity.

Q7: What is your typical lead time & trade terms?

A: Regular orders: 7–15 days. Urgent/bulk: priority slot possible. Terms: FOB, CFR, DDP, LCL/FCL container111. Standard documentation: CO, Mill Test Certificate, SGS/BV third-party inspection per shipment.

11. Ordering Process, Warranty & Client Support

- How to Order: RFQ via email, drawing/spec confirmation, proforma invoice.

- Payment: 30% TT advance / L/C at sight, balance before shipment.

- Warranty: All Galvanized Wire shipped with 24–36 months warranty against zinc delamination structure cracks under normal use.

- Client Support: Pre-sales engineering advice, sample coil shipment, technical documentation, and 48-hour aftersales response.

Application Snapshot: Global Success Stories

- Oil & Gas Pipelines (Indonesia): Used Galvanized Wire armoring for cathodic protection. Wire remained >96% zinc-covered after 6 years.

- Vineyard Trellising (Spain): Enhanced yield by 17% due to rust-free, high-flex wire mesh, reducing annual replacement cycles.

- Industrial Fencing (USA): Large logistic center saved 22% material cost versus PVC-coated alternatives; annual inspections confirm no red rust after 3 monsoons.

12. Further Reading & Industry References