Cutting Wire is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of cutting tools, grinding tools, and cutting tools. This article explores how SHENZHOU TIKE METAL CO., LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

In toolmaking and precision parts production, Cutting Wire is the consumable that translates machine capability into dimensional accuracy, surface finish, and throughput. In wire-cut EDM (electrical discharge machining) and wire-saw operations, the wire’s metallurgy, coating, diameter tolerance, tensile strength, and straightness directly influence kerf stability and discharge efficiency. Typical EDM Cutting Wire solutions include plain brass, zinc-coated brass, and molybdenum/tungsten variants, offered in common diameters such as 0.10–0.25 mm for fine to general-purpose cutting. Key performance parameters decision makers track include breakage rate under high tension, conductivity for faster cutting regimes, spool-to-spool consistency, and compatibility with major EDM platforms.

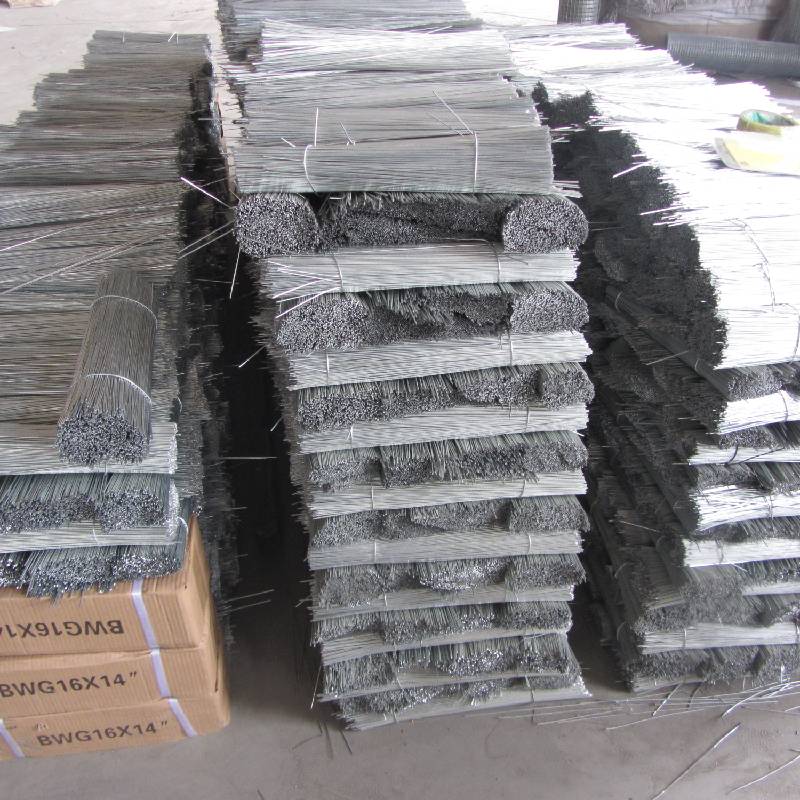

SHENZHOU TIKE METAL CO., LTD. supplies industrial-grade Cutting Wire engineered for repeatable performance in the Special Equipment Manufacturing Industry. With attention to roundness, surface uniformity, and tight diameter control, the company helps reduce wire vibration and spark instability—two common causes of edge taper and poor finish on hard tool steels, carbide, and die materials. Whether you are producing molds, punches, dies, or cutting tool components, partnering with a reliable wire manufacturer ensures stable unattended runs and predictable cost per part.

In the Manufacturing of cutting tools, grinding tools, and cutting tools, Cutting Wire plays a decisive role in slotting, profile generation, and clearance creation on tool bodies and inserts. EDM wire enables complex contours on HSS and carbide, precision slitting of saw blanks, and pre-forming of geometries before grinding finishes the cutting edges. For mold bases and toolholders, stable wire helps maintain perpendicularity, minimize recast layers, and reduce secondary operations. Zinc-coated brass wire often supports higher speeds and better flushing in tall workpieces, while molybdenum wire offers high durability in certain process setups.

For B2B decision makers, total cost of ownership matters more than spool price alone. The right Cutting Wire reduces downtime, improves first-pass yield, and shortens cycle time—delivering a better cost per part. Durable, dimensionally consistent wire sustains higher tensions and cutting speeds, which can enable unattended shifts and better machine utilization. Over time, fewer wire breaks and less rework translate into measurable ROI, especially in high-mix toolmaking where changeovers are frequent and delivery windows are tight.

Sustainability in precision manufacturing increasingly centers on energy efficiency, material circularity, and compliance. For Cutting Wire, that means choosing alloys and coatings that deliver higher cutting speeds with lower consumption, and setting up recycling pathways for metallic scrap. As regulations such as RoHS/REACH and customer ESG requirements evolve, traceable materials data and transparent sourcing become strategic advantages. Market trends include faster, smarter EDM systems that demand tighter wire tolerances, improved coatings for tall workpieces, and data-driven process control for stable unattended machining.

SHENZHOU TIKE METAL CO., LTD. takes a forward-looking approach—prioritizing consistency, process control, and collaboration on packaging optimization and responsible material handling. By aligning wire performance with your throughput and quality goals, the company helps reduce scrap, rework, and energy-hungry secondary finishing. The result is a practical path to lower environmental impact without compromising productivity in cutting tool and grinding tool manufacturing.

From complex tool profiles to precise slots and forms, Cutting Wire underpins accuracy, finish, and throughput across the Special Equipment Manufacturing Industry and the Manufacturing of cutting tools, grinding tools, and cutting tools. By combining stable metallurgy with tight dimensional control, SHENZHOU TIKE METAL CO., LTD. enables predictable cost per part and confident unattended machining. If you are upgrading EDM performance or standardizing consumables across plants, consider partnering for consistent wire supply and technical support.

RELATED PRODUCTS