Welded steel grating, a crucial component in industrial applications, is renowned for its superior strength and durability. This versatile material is crafted through an intricate process of welding crossbars and bearing bars together to form a sturdy grid structure. As more industries recognize the importance of robust, reliable flooring solutions, welded steel grating has emerged as a preferred choice due to its numerous advantages.

In the realm of industrial flooring, safety is paramount. Welded steel grating offers excellent slip resistance, making it ideal for environments prone to spills or moisture accumulation. Its open grid design efficiently drains liquids, minimizing the risk of workplace accidents. This feature is particularly beneficial in settings such as oil refineries, chemical plants, and food processing facilities, where maintaining a safe and dry working surface is crucial. The material's high load-bearing capacity further underscores its suitability for heavy-duty applications, supporting the weight of equipment and vehicular traffic without compromising structural integrity.

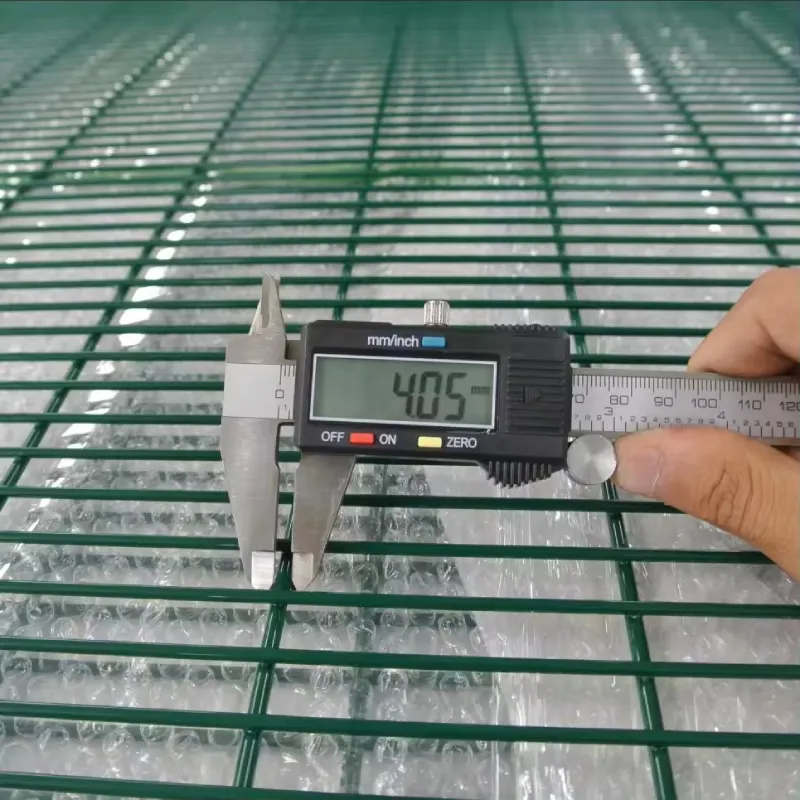

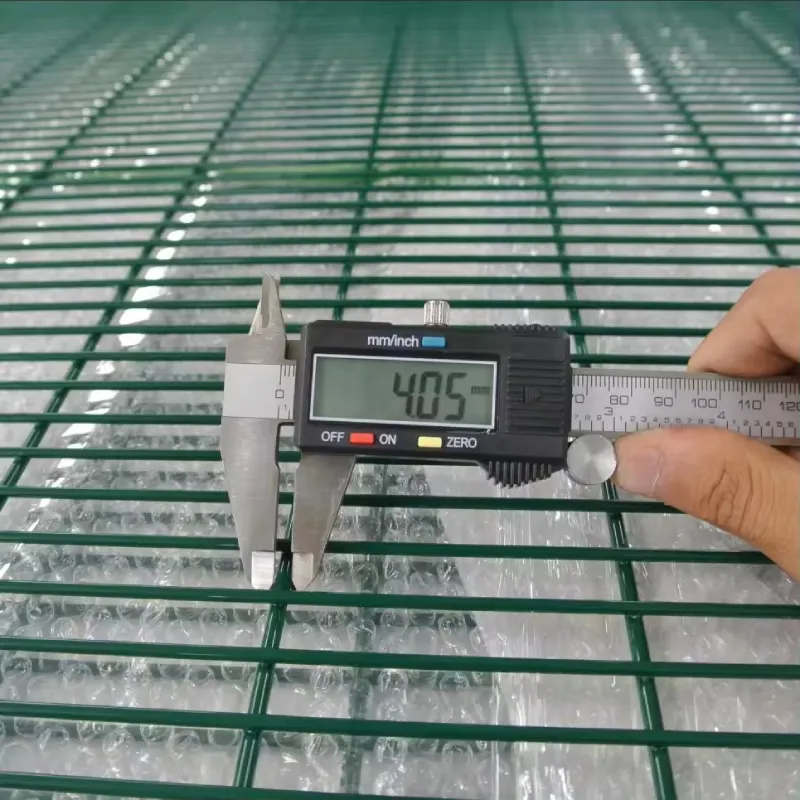

From an expertise perspective, the production of welded steel grating requires a deep understanding of metallurgical properties and welding techniques. Each piece is crafted with precision, ensuring that the welds are consistent and secure. This meticulous attention to detail guarantees that the grating can withstand harsh environmental conditions, including extreme temperatures and corrosive substances, enhancing its longevity. Whether used in walkways, platforms, or mezzanines, this product demonstrates resilience, a testament to the expertise invested in its creation.

Authoritativeness in the field of welded steel grating is reflected in its comprehensive range of applications. Industries including manufacturing, construction, and transportation have long relied on this material for its exemplary performance. Leading manufacturers, known for their extensive research and innovation, continue to refine their products, incorporating advanced welding technologies and high-grade steel to meet evolving industry standards. This commitment to quality and continuous improvement reinforces the grating's reputation as the authoritative choice for robust industrial flooring solutions.

welded steel grating

Trustworthiness is integral to the adoption of welded steel grating in critical applications. Certification from industry standards organizations, such as the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA), validates the material's compliance with safety and performance benchmarks. Customers can rely on these certifications as a measure of quality assurance, knowing that the grating has undergone rigorous testing and inspection.

The installation process of welded steel grating also contributes to its appeal. Its lightweight yet strong structure facilitates easy handling and placement, reducing installation time and labor costs. Furthermore, it can be customized to fit specific dimensions and designs, offering flexibility in various project requirements. This adaptability is particularly advantageous in retrofitting projects, where standard-sized grating may not suffice, ensuring a seamless integration into existing infrastructure.

Moreover, the sustainability aspect of welded steel grating should not be overlooked. Steel is one of the most recycled materials globally, and grating made from recycled steel further enhances its environmental credentials. The recycling process conserves natural resources, reduces emissions, and minimizes landfill waste, aligning with the growing emphasis on sustainable practices across industries. Choosing welded steel grating not only benefits operational safety and efficiency but also supports environmental stewardship.

In conclusion, welded steel grating stands as a pillar of industrial infrastructure, offering unparalleled strength, safety, and versatility. Its development and application are backed by a wealth of expertise, authoritative endorsements, and a commitment to safety and sustainability. As businesses seek dependable and efficient solutions for their flooring needs, welded steel grating continues to be an unrivaled choice, trusted by industry leaders worldwide to uphold safety standards and optimize operational effectiveness.