When it comes to leveraging industrial materials within construction and engineering sectors, steel grating plates emerge as pivotal components that offer unmatched durability, strength, and versatility. This article delves into the multi-faceted utility of steel grating plates, backed by authentic industry expertise, and provides insights that underscore their relevance and superiority in various applications.

Steel grating plates are engineered through a process of electrofusion, which involves interlocking perpendicular metal bars. The choice of steel in these constructions is deliberate; its high tensile strength and resistance to environmental wear make it an ideal candidate for demanding applications. Furthermore, these grating plates are often treated with protective coatings such as galvanization, enhancing their ability to resist corrosion and extend their service life — a crucial consideration in environments subject to moisture or chemical exposure.

In practice, the application of steel grating plates spans numerous industries. Within the construction sector, they serve as essential elements in creating walkways, stairs,

and platforms. Their open-grid design ensures efficient drainage and ventilation, mitigating hazards associated with water accumulation, such as slipping. This feature provides not only an enhancement of safety protocols but also simplifies maintenance efforts, as debris does not easily accumulate on the surface.

Industrial facilities, particularly those involved in chemical and petrochemical processing, benefit significantly from steel grating plates. Given the harsh operating environments and the need for robust flooring solutions that can withstand substantial weight and corrosive substances, these grating plates stand as a testament to reliability. Their ability to endure heavy static and dynamic loads without compromising structural integrity makes them indispensable.

Moreover, the customizability of steel grating plates positions them as a flexible solution tailored to specific project requirements. Industries recognize the advantage of being able to select from various bar sizes, spacing, and finishes. This adaptability ensures that steel grating can be optimized not only for functional needs but also for aesthetic integration within modern architectural designs.

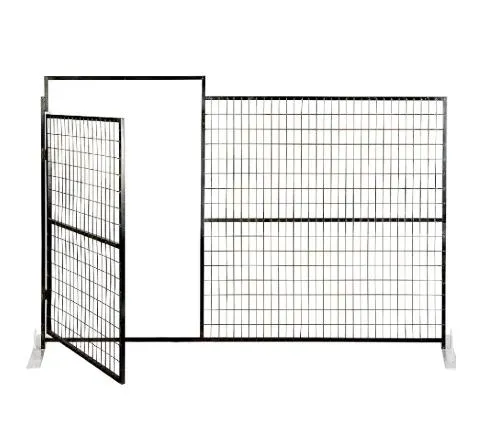

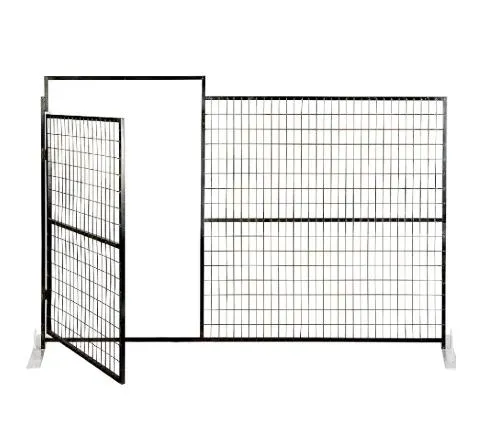

steel grating plate

The credibility of steel grating plates is further bolstered by rigorous testing and compliance with international safety and quality standards. Renowned manufacturers are committed to thorough quality assurance processes, certifying that every grating plate delivered to market adheres to established benchmarks for safety and performance. This commitment to quality is indicative of the industry’s dedication to sustainability and innovation.

Expert insights underscore that as infrastructure developments intensify globally, the demand for reliable materials like steel grating plates will parallel this growth. For stakeholders responsible for specifying materials in projects, understanding the strategic benefits of steel grating can influence decisions toward sustainable practices. Encouragingly, steel, when recycled, retains its original properties, supporting broader initiatives in resource conservation and reducing ecological footprints.

Ultimately, trust in utilizing steel grating plates is reinforced by the convergence of their practical benefits with economic efficiencies. Despite the initial investment costs, their longevity and low maintenance requirements translate to reduced long-term expenses. Forward-thinking project managers and engineers regard this attribute as a persuasive factor in deciding to incorporate steel grating plates within their frameworks.

In conclusion, the authoritative stance on steel grating plates is that they are not merely components but essential assets that elevate project outcomes. Their integration reflects a commitment to superior quality, safety, and sustainability — traits that resonate with the ever-evolving demands of modern industry. For enterprises keen on fortifying their structural initiatives, steel grating plates offer a tangible foundation upon which future innovations can thrive.