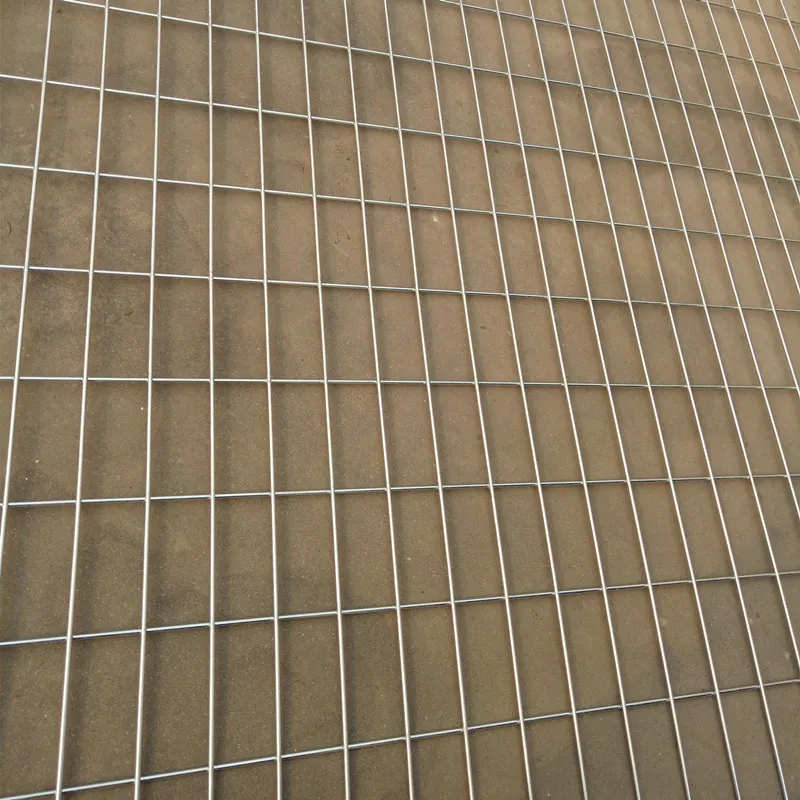

If you’re weighing materials for aviaries or breeding rooms, the first thing I tell buyers is simple: start with the right mesh. I’ve toured facilities that sparkle and some that… don’t. The difference often comes down to finish and aperture. For a dependable balance of hygiene, cost, and durability, welded mesh for bird cages—specifically electro galvanized panels—keeps popping up in specs from mid-size breeders to zoo back-of-house teams.

Base wire is low-carbon steel (often Q195). The wire is electro-galvanized before welding (that’s the manufacturer’s note, and it tracks with the smooth finish I’ve seen). Next comes resistance spot-welding on a flat-bed line, followed by de-slagging, light passivation, and panel sizing. Typical QA pulls include zinc coating measurements (ASTM A641), tensile checks (ASTM A370), and aperture tolerance mapping. In salt-spray tests (ISO 9227), many panels hold 120–240 h NSS without red rust—real-world use may vary, of course.

| Parameter | Typical Range | Notes |

|---|---|---|

| Wire diameter | ≈ 1.0–2.5 mm | Pick 1.2–1.6 mm for small species; heavier for macaws. |

| Aperture (opening) | 6×6 to 25×25 mm | Tight mesh reduces escape and rodent ingress. |

| Zinc coating | ≈ 8–20 g/m² | Electro-galv; smooth finish aids cleaning. |

| Panel size | ≈ 0.9×2.0 m, 1.2×2.4 m | Custom cuts reduce onsite trimming. |

| Tensile strength | ≈ 350–550 MPa | Check per batch; macaws chew-test everything. |

Look for coating verification (ASTM A641), mechanical testing (ASTM A370), and optional ISO 9227 salt-spray reports. Vendors often supply RoHS/REACH statements and SGS material checks. Indoors, panels can exceed 10 years; outdoors, factor pollution and cleaners. Many customers say a gentle neutral pH wash extends finish noticeably.

| Option | Corrosion resistance | Approx. cost | Best for |

|---|---|---|---|

| Electro-galv welded (this product) | Medium | $ | Indoor cages, covered flights |

| PVC-coated welded | Medium–High | $$ | Humid areas; softer touch |

| Stainless 304 | High | $$$ | Harsh coastal or disinfectant-heavy use |

| Low-zinc generic mesh | Low | $ | Short-term enclosures; not recommended long-term |

Custom apertures, panel sizes, and edging trims help avoid sharp ends. Crates ship from: East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui City, Hebei Province. Lead times are reasonable; I’ve seen quick-turn batches for seasonal ramp-ups.

Bottom line: electro-galvanized panels hit a sweet spot—clean look, solid hygiene, friendly cost. Stainless owns the extremes, sure, but for most cages and flights, this is the pragmatic choice.

RELATED PRODUCTS