Introduction

Perforated metal mesh has become an essential component in modern industrial and architectural applications, offering a unique combination of durability, functionality, and aesthetic appeal. Perforated Metal Mesh is a versatile material designed to meet the demands of diverse industries. This article explores the key features, advantages, technical specifications, and application scenarios of this innovative product, while also providing insights into the company behind it: Shenzhou Tike Metal Co., Ltd..

Key Features of Perforated Metal Mesh

The Perforated Metal Mesh is engineered to deliver exceptional performance across a wide range of applications. Its standout features include:

- High Opening Rate: The mesh achieves an opening rate of over 30%, ensuring excellent air permeability and light transmission. This makes it ideal for ventilation systems, filters, and acoustic applications.

- Lightweight Design: Due to its high opening rate, the material is significantly lighter than solid metal sheets of the same size, reducing transportation and installation costs.

- Corrosion Resistance: Available in various metal grades, the mesh offers robust resistance to corrosion, making it suitable for harsh environments.

- Customizable Aesthetics: The perforation patterns can be tailored to match specific design requirements, allowing for creative and visually appealing solutions.

- Easy Processing: The material is easy to cut, bend, weld, and shape, enabling seamless integration into complex structures.

- Environmental Friendliness: The mesh is fully recyclable, aligning with sustainable manufacturing practices.

Advantages of Perforated Metal Mesh

The Perforated Metal Mesh provides numerous advantages that make it a preferred choice for engineers, architects, and manufacturers:

- Enhanced Functionality: The high opening rate allows for efficient airflow and light transmission, which is critical in applications like air filters, soundproofing, and lighting systems.

- Cost-Effective: Its lightweight nature reduces material and transportation costs, while its durability minimizes maintenance expenses over time.

- Design Flexibility: The ability to customize hole shapes and patterns enables the creation of unique, industry-specific solutions.

- Strength and Durability: Despite its lightweight, the mesh maintains high tensile strength, ensuring long-term performance in demanding environments.

- Sustainability: The recyclability of the material supports eco-friendly practices, appealing to environmentally conscious consumers.

Technical Specifications

The Perforated Metal Mesh is available in a wide range of specifications to suit different applications. The following table outlines the key parameters:

| Parameter | Details |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm–10mm |

| Opening Rate | 5%–80% |

| Aperture | 0.5mm–200mm |

| Hole Distance | 1mm–200mm |

| Size | 1m x 2m, 1.22m x 2.44m, 1.5m x 3m, etc. |

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa/100MPa |

| Hardness | 150–200HB/30–50HB |

| Area Density | 20%–60% |

Application Scenarios

The Perforated Metal Mesh is widely used in both industrial and architectural contexts. Some common applications include:

- Industrial Filters: Used in oil filters and grain sifters to separate particles and ensure efficient processing.

- Soundproofing: The mesh's design helps absorb and block noise, making it ideal for acoustic panels and partitions.

- Ventilation Systems: Its high opening rate allows for optimal airflow in HVAC systems and industrial ventilation.

- Architectural Design: Customizable patterns are used in facades, ceilings, and decorative elements to enhance aesthetics while maintaining functionality.

- Automotive Industry: Applied in exhaust systems, air filters, and interior components for its durability and lightweight properties.

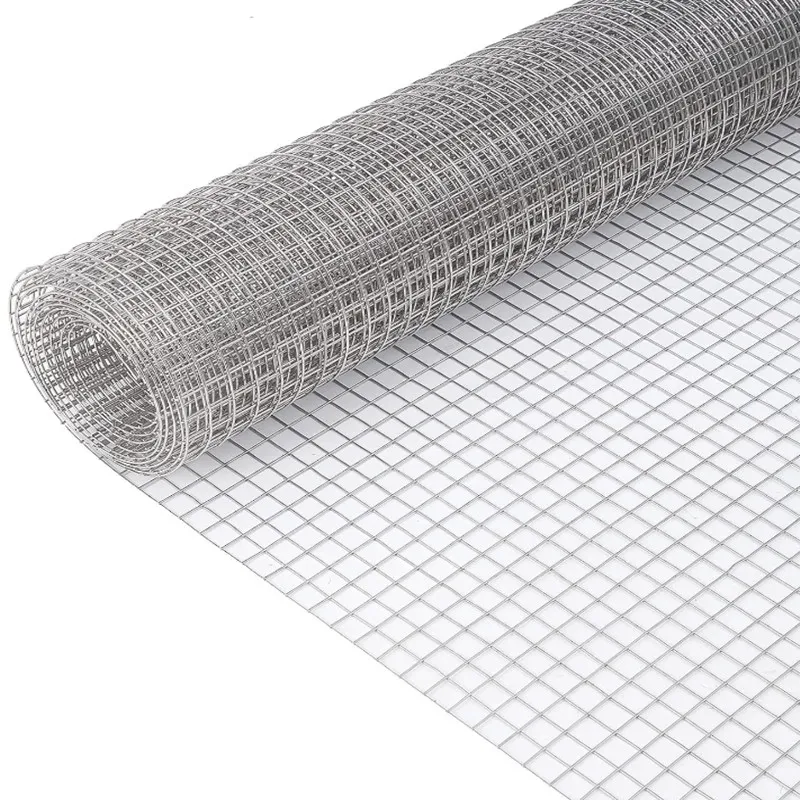

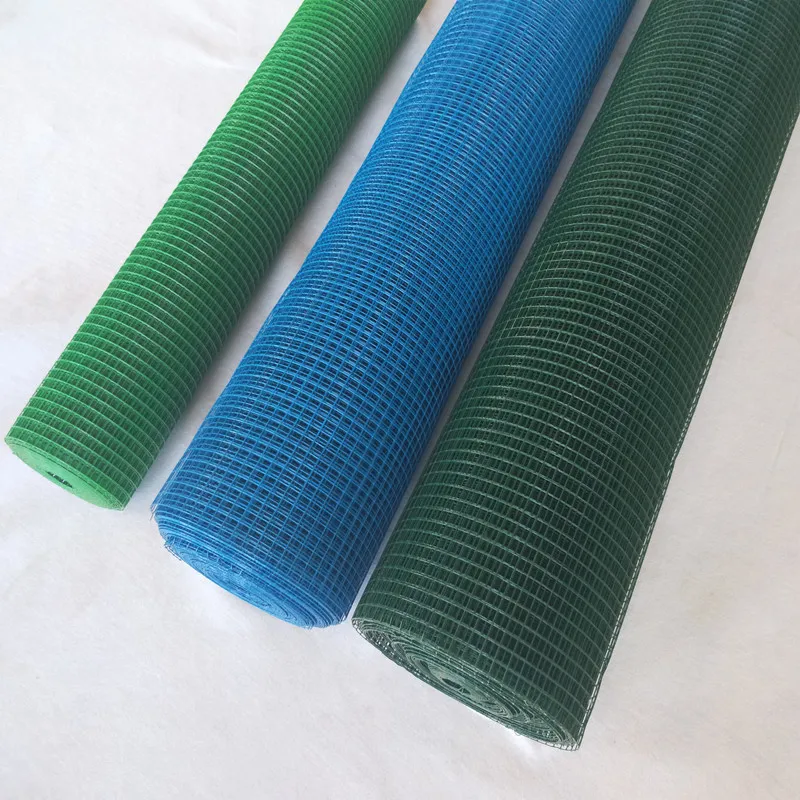

For a visual representation of the Perforated Metal Mesh, refer to the images below:

About Shenzhou Tike Metal Co., Ltd.

Shenzhou Tike Metal Co., Ltd. is a leading manufacturer of high-quality metal products, including Perforated Metal Mesh. With a focus on innovation and customer satisfaction, the company has established itself as a trusted name in the industry. Their commitment to quality is reflected in the precision and durability of their products, which are used in applications ranging from industrial machinery to architectural design.

Shenzhou Tike Metal Co., Ltd. is known for its advanced manufacturing capabilities and adherence to international standards. The company's state-of-the-art facilities and skilled workforce ensure that every product meets the highest quality benchmarks. Additionally, their dedication to sustainability is evident in the recyclability of their materials and the reduction of waste in their production processes.

For more information about Shenzhou Tike Metal Co., Ltd., visit their official website or contact their customer service team.

Conclusion

The Perforated Metal Mesh is a versatile and durable solution that meets the demands of modern industries. Its unique combination of high opening rate, lightweight design, and corrosion resistance makes it an ideal choice for a wide range of applications. With Shenzhou Tike Metal Co., Ltd. as a reliable manufacturer, users can trust in the quality and performance of this product. Whether for industrial, architectural, or commercial use, the Perforated Metal Mesh continues to set the standard for innovation and functionality.

Authoritative Citations

The information provided in this article is supported by standards and research from reputable organizations. For further details, refer to the following sources:

- National Institute of Standards and Technology (NIST) – NIST provides guidelines and research on material properties and manufacturing standards that underpin the development of high-performance metal products.

- NIST Publications – Research papers and technical reports on material testing and industrial applications.

- NIST Standards and Measurements – Information on measurement practices and quality assurance in manufacturing.