Square Wire Mesh is a key solution in the building materials industry, specifically within metal material and Wire mesh products. This article explores how SHENZHOU TIKE METAL CO., LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

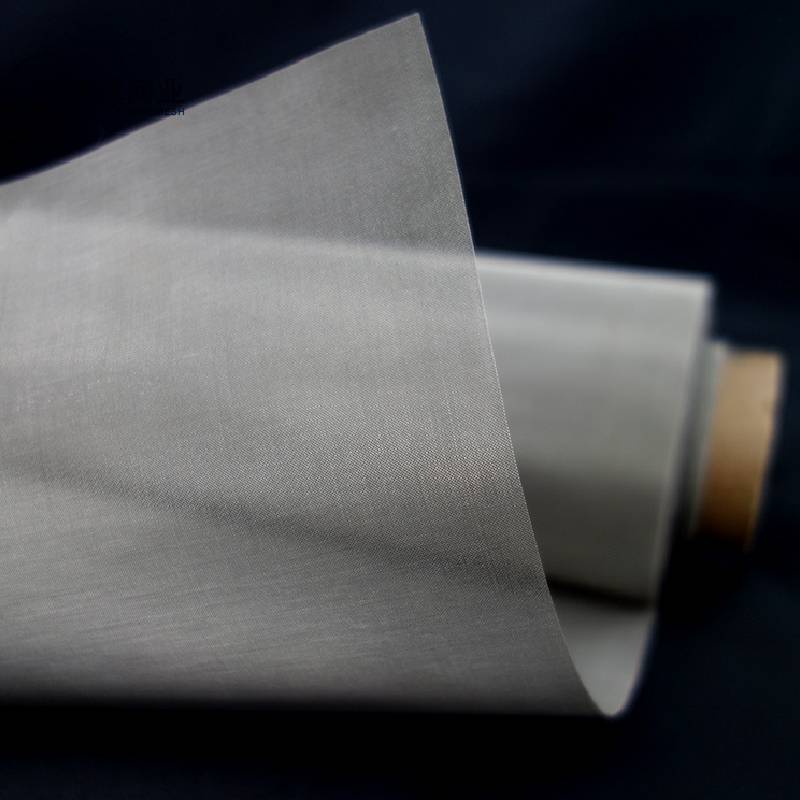

Square Wire Mesh is a precision-engineered metal mesh with uniformly spaced, square-shaped openings. It is fundamental in building materials and metal material applications where accurate aperture control, mechanical strength, and visibility/airflow are required. Available as woven square wire cloth or welded square opening mesh, it serves screening, safety, filtration, partitioning, and architectural needs across construction, manufacturing, and infrastructure projects. SHENZHOU TIKE METAL CO., LTD. supplies Square Wire Mesh in a range of materials—galvanized steel, stainless steel (304/316), and low-carbon steel—with options for PVC coating to extend service life in corrosive or outdoor environments.

Typical specifications include mesh counts from coarse (2–4 mesh) to fine (up to ~80–100 mesh), wire diameters from approximately 0.20–4.0 mm, and standard widths up to 2.0 m, delivered in rolls or cut-to-size panels. Plain weave dominates for woven square cloth due to its stability and predictability under load, while welded square mesh provides high rigidity for guards and infills. Produced in accordance with common industry practices and applicable standards such as ASTM E2016 and ISO 9044 (where specified), SHENZHOU TIKE METAL CO., LTD. focuses on tight tolerances for aperture and wire diameter to ensure consistent throughput in screening and dependable fit during installation.

In wire mesh product portfolios, Square Wire Mesh stands out for its balance of strength, open area, and cost efficiency. It is widely used for safety guards around equipment, machine enclosures, fencing and perimeter control, partition walls, plaster/stucco reinforcement, architectural infills, sieving and grading of aggregates or grains, and as a support layer in multilayer filtration assemblies. Stainless steel variants excel in food, pharmaceutical, and chemical processing thanks to corrosion resistance and cleanability, while galvanized or PVC-coated meshes offer economical durability for outdoor construction, agriculture, and infrastructure.

Key advantages for B2B buyers include predictable aperture uniformity for process control, high flatness for easy framing, and customizable formats (rolls, sheets, framed panels). SHENZHOU TIKE METAL CO., LTD. leverages mature weaving and welding lines, strict QC, and flexible finishing (pre-/post-galvanizing, passivation, powder/PVC coating) to tailor performance to site conditions. The company’s engineering team supports specification matching—mesh count, wire gauge, open area, and alloy—to meet project KPIs such as airflow, light transmission, load-bearing, and corrosion lifecycle, giving procurement teams a reliable path from RFQ to on-time delivery.

Total cost of ownership for Square Wire Mesh hinges on material choice, coating, and correct sizing. Galvanized or PVC-coated carbon steel often delivers the best upfront value for perimeter and partition uses, while stainless steel delivers lower lifecycle cost in corrosive or hygiene-critical environments by minimizing replacements and cleaning downtime. SHENZHOU TIKE METAL CO., LTD. helps buyers model ROI by balancing mesh count and wire diameter for adequate strength without over-specifying weight, which reduces transport and frame costs. Repeat customers in metal fabrication and construction report reduced rework due to mesh flatness and consistency, as well as faster installation when panels arrive cut-to-size with pre-formed edges.

Maintenance is straightforward: periodic inspection, light cleaning to remove debris, and recoating or touch-up (for coated meshes) where impacts occur. Stainless grades typically require only routine washdowns. Feedback from the sector highlights three UX benefits—clean edges that improve safety on-site, dependable aperture uniformity for screening yield stability, and packaging that protects rolls and panels from transit deformation. These factors collectively improve project schedule certainty and lower the risk of costly on-site adjustments.

Sustainability priorities in the building materials ecosystem are reshaping specifications for wire mesh products. Steel’s high recyclability, the longevity of stainless alloys, and protective coatings that extend service life collectively reduce embodied carbon over a project’s lifecycle. Growing attention to ESG reporting and green building frameworks encourages durable, low-maintenance components that minimize replacement cycles and waste. In parallel, market demand is expanding for meshes that combine structural function with design aesthetics—such as square meshes used in façades and interior partitions with defined transparency and airflow targets.

SHENZHOU TIKE METAL CO., LTD. aligns with these trends by offering material choices that support circularity and by optimizing production for yield and energy efficiency. Upon request, meshes can be supplied to meet specific compliance and documentation requirements (e.g., material traceability, RoHS/REACH-related requests where applicable). Engineering support helps specifiers right-size mesh parameters to reduce overuse of raw material without compromising performance. The result is Square Wire Mesh solutions that satisfy both technical specifications and sustainability objectives for developers, EPCs, and OEMs.

Square Wire Mesh remains a versatile, high-value component across building materials, metal material, and wire mesh products, delivering strength, uniformity, and configurable open area for safety, screening, and architectural applications. SHENZHOU TIKE METAL CO., LTD. pairs reliable manufacturing with technical support to help B2B decision makers optimize specifications, control costs, and streamline installation. If you’re planning a new build, retrofit, or product line using Square Wire Mesh, our team is ready to assist from selection to delivery. Contact us: email: info@tikemetal.com — Visit our website: https://www.tikemetal.com

RELATED PRODUCTS