Aus Temp Fencing is a key solution in the manufacturing industry, specifically within Fabricated metal products and Fence manufacturing. This article explores how SHENZHOU TIKE METAL CO., LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

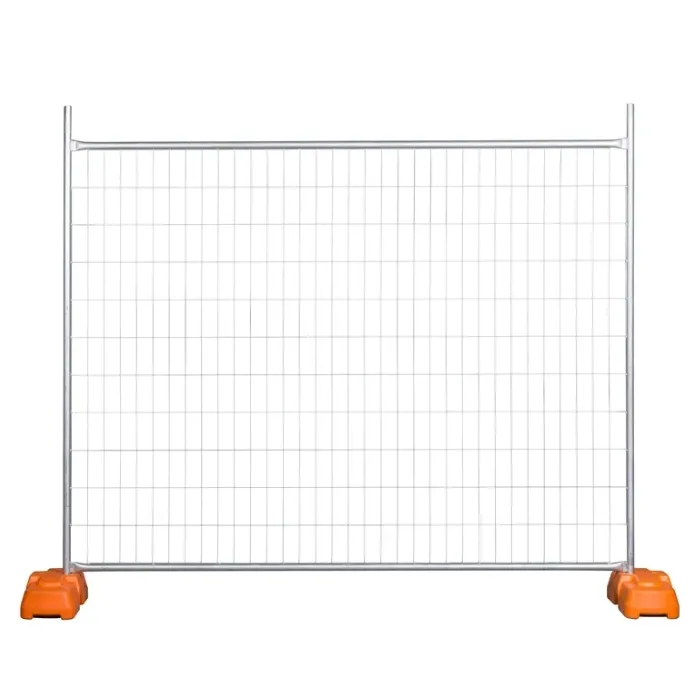

Aus Temp Fencing refers to Australian-style temporary fence panels engineered for fast deployment, site security, and public safety. Within fabricated metal products, these modular systems represent the intersection of precision wire fabrication and structural tubing—delivering a reliable barrier that stands up to demanding construction, event, mining, and infrastructure environments. For B2B decision makers balancing safety compliance and cost control, standardized panel dimensions and robust galvanizing make procurement and fleet management straightforward across multiple projects and seasons.

SHENZHOU TIKE METAL CO., LTD. leverages jig-based fabrication, repeatable weld quality, and rigorous inspection to deliver consistent, project-ready panels. From wire selection to post-galvanizing checks, the company’s process control helps rental depots and contractors minimize downtime and reduce repair churn across their temp fence fleets.

In fence manufacturing, Aus Temp Fencing stands out for its modularity, interchangeability, and serviceability—the attributes that drive utilization for rental companies and large contractors. Panels deploy quickly for construction perimeters, crowd control at events, and asset protection around utilities or civil works. In agriculture and rural events, temporary lines can complement permanent wire livestock fencing by creating controlled access points, short-term corrals, or exclusion zones without disturbing existing infrastructure.

Because components are standardized, installers can typically secure long runs with two-person teams and minimal tooling. That simplicity shortens setup and pack-down time—critical during night works, lane closures, or tight event schedules—while delivering the reliable containment of a wire mesh fence system tailored for temporary duty.

Total cost of ownership for Aus Temp Fencing is influenced by panel longevity, repairability, and utilization rate across multiple projects. Galvanized finishes and robust mesh-to-frame welds help extend service life in coastal, high-UV, or high-traffic environments. For rental and construction fleets, the ROI typically improves as panels rotate through recurring works such as subdivision builds, utilities maintenance, and seasonal events—reducing per-project spend compared to single-use barriers.

SHENZHOU TIKE METAL CO., LTD. supports TCO with quality-focused production and packaging that reduces transit scuffs. Clear labeling and palletization assist inventory turns and help rental depots process in/out movements with less handling time.

Sustainability in fence manufacturing centers on durability, reusability, and end-of-life recyclability. Aus Temp Fencing aligns closely with these priorities: galvanized steel panels are designed for repeated deployment, minimizing single-use materials and reducing waste generation per project. Recycled rubber or concrete feet, modular repairs, and component interchangeability further support circular economy strategies in the built environment.

As procurement teams pursue ESG-aligned outcomes, choosing high-quality, long-life Aus Temp Fencing delivers measurable benefits: fewer replacements, reduced site waste, and compatibility with recycled materials in ancillary components.

For B2B buyers in manufacturing and Fence manufacturing, Aus Temp Fencing offers a robust, modular approach to site safety and access control. With anti-climb mesh, durable frames, and long-life galvanizing, the system performs across construction, events, and asset protection—complementing permanent solutions like wire livestock fencing where temporary control is needed. SHENZHOU TIKE METAL CO., LTD. earns trust through consistent fabrication quality and responsive support.

RELATED PRODUCTS