Perforated metal mesh has become a cornerstone in modern industrial and architectural applications due to its exceptional combination of functionality, durability, and aesthetic appeal. As a leading manufacturer, Shenzhou Tike Metal Co., Ltd. offers a comprehensive range of Sheet Plate Punching Mesh tailored to meet diverse industry needs. This article explores the features, advantages, technical specifications, application scenarios, and company background of this versatile product.

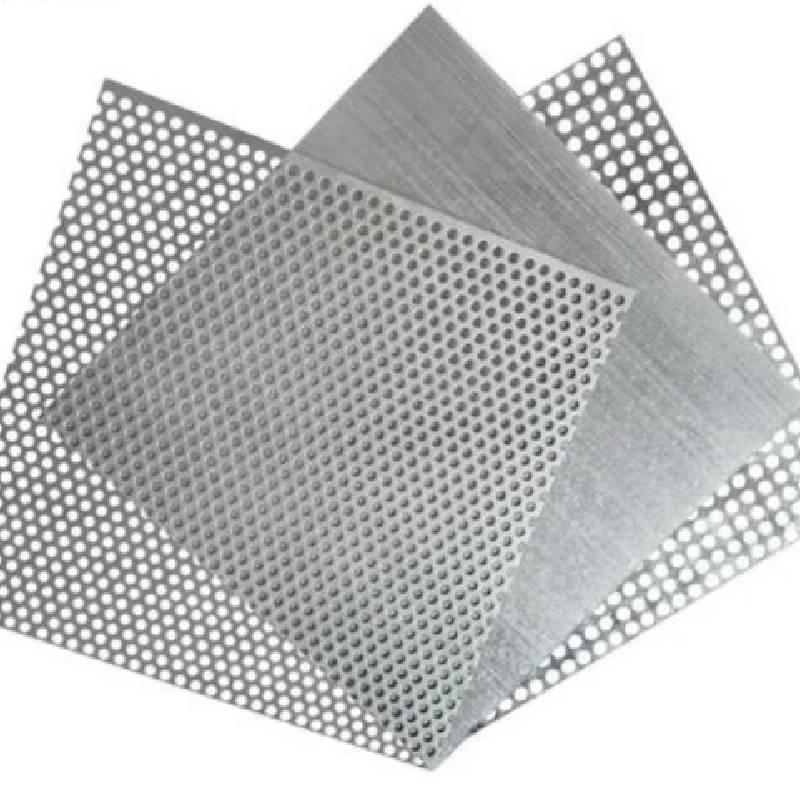

Perforated metal mesh is engineered to deliver optimal performance across a wide range of applications. Its unique design and material properties make it a preferred choice for industries requiring precision, strength, and adaptability.

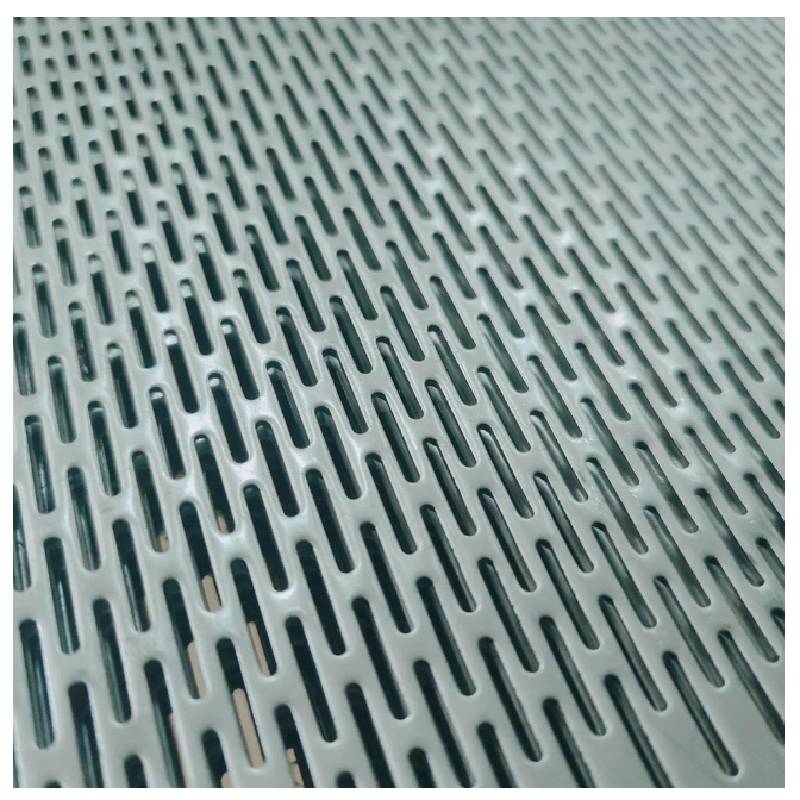

One of the standout features of Perforated Metal Mesh is its high opening rate, which can exceed 30%. This design allows for excellent air permeability and light transmission, making it ideal for applications such as ventilation systems, soundproofing, and architectural facades. The strategic placement of holes ensures minimal obstruction while maintaining structural integrity.

The high opening rate not only enhances airflow but also reduces the overall weight of the mesh compared to solid metal sheets of the same size. This lightweight characteristic makes it easier to handle and install, while the material's inherent strength ensures long-term durability. Whether used in industrial machinery or building construction, the mesh retains its structural stability under various conditions.

Manufactured from high-quality metal plates, Perforated Metal Mesh is available in materials that offer excellent corrosion resistance. This makes it suitable for environments exposed to moisture, chemicals, or extreme weather conditions. The corrosion-resistant properties extend the product's lifespan, reducing maintenance costs and ensuring consistent performance over time.

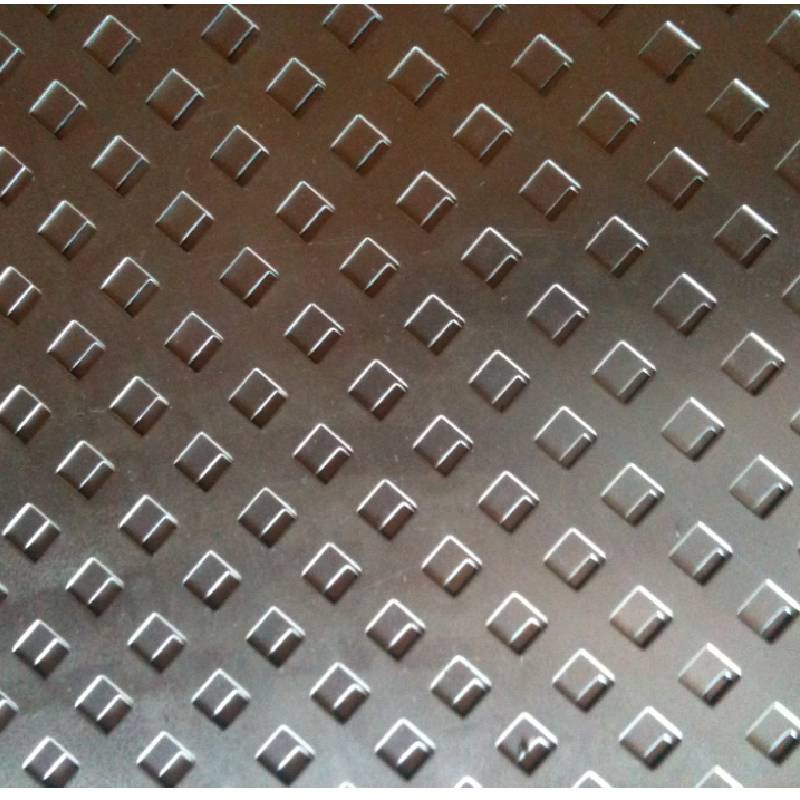

One of the most appealing aspects of perforated metal mesh is its ability to be customized. The opening shapes, sizes, and patterns can be tailored to meet specific design requirements. This versatility allows architects and engineers to integrate the mesh seamlessly into modern structures, creating visually striking elements such as decorative panels, acoustic ceilings, and ventilation grilles.

The material's malleability enables easy cutting, bending, welding, and other fabrication processes. This flexibility ensures that Perforated Metal Mesh can be adapted to complex designs and unique project specifications. Its compatibility with standard manufacturing techniques also simplifies the production and installation process, saving time and resources.

Perforated metal mesh is fully recyclable, aligning with global efforts to promote sustainable practices. Its reusability reduces waste and supports eco-friendly manufacturing processes. By choosing this product, industries can contribute to environmental conservation without compromising on performance or quality.

The following table provides a detailed overview of the technical parameters of Perforated Metal Mesh:

| Parameter | Details |

|---|---|

| Product Name | Perforated Metal Mesh |

| Keywords | Sheet Plate Punching Mesh |

| Thickness | 0.3mm - 10mm |

| Opening Rate | 5% - 80% |

| Aperture | 0.5mm - 200mm |

| Hole Distance | 1mm - 200mm |

| Size | 1m x 2m, 1.22m x 2.44m, 1.5m x 3m, etc. |

| Shape | Square, Round, Oval, etc. |

| Tensile Strength | 500MPa / 100MPa |

| Hardness | 150-200HB / 30-50HB |

| Area Density | 20% - 60% |

The versatility of Perforated Metal Mesh makes it a valuable asset in both industrial and architectural contexts. Its ability to balance functionality and aesthetics has led to its widespread adoption across various sectors.

In industrial settings, the mesh is commonly used in Sheet Plate Punching Mesh for applications such as oil filters, grain sifters, and ventilation systems. The high opening rate ensures efficient filtration and airflow, while the corrosion-resistant properties make it suitable for harsh environments. Additionally, its strength and durability make it an ideal material for machinery components, conveyor belts, and protective barriers.

Architecturally, Perforated Metal Mesh is used to create visually appealing and functional elements such as soundproofing panels, decorative facades, and acoustic ceilings. The customizable patterns allow for unique designs that enhance the aesthetic value of buildings. Its light transmission properties also contribute to energy efficiency by reducing the need for artificial lighting in interior spaces.

Shenzhou Tike Metal Co., Ltd. is a leading manufacturer specializing in the production of high-quality metal products, including Perforated Metal Mesh. With decades of experience in the industry, the company has established itself as a trusted supplier to clients worldwide. Their commitment to innovation, quality control, and customer satisfaction ensures that their products meet the highest standards.

Shenzhou Tike Metal Co., Ltd. adheres to strict manufacturing protocols to guarantee the reliability and performance of its products. The company's state-of-the-art facilities and advanced technology enable it to produce customized solutions that cater to the specific needs of its clients. By combining technical expertise with a customer-centric approach, the company has built a strong reputation in the global market.

Perforated Metal Mesh from Shenzhou Tike Metal Co., Ltd. exemplifies the perfect blend of functionality, durability, and aesthetics. Its high opening rate, lightweight design, corrosion resistance, and customizable features make it a versatile solution for a wide range of applications. Whether used in industrial machinery or architectural projects, this product delivers exceptional value and performance. For those seeking a reliable and sustainable material, Sheet Plate Punching Mesh is an ideal choice.

1. National Institute of Standards and Technology (NIST) - Standards for metal mesh and filtration systems.

2. ASTM International - Specifications for metal sieves and filters.

3. International Organization for Standardization (ISO) - Guidelines for material testing and quality control.

For more information about Perforated Metal Mesh and Shenzhou Tike Metal Co., Ltd., visit their official website: Shenzhou Tike Metal Co., Ltd.

RELATED PRODUCTS