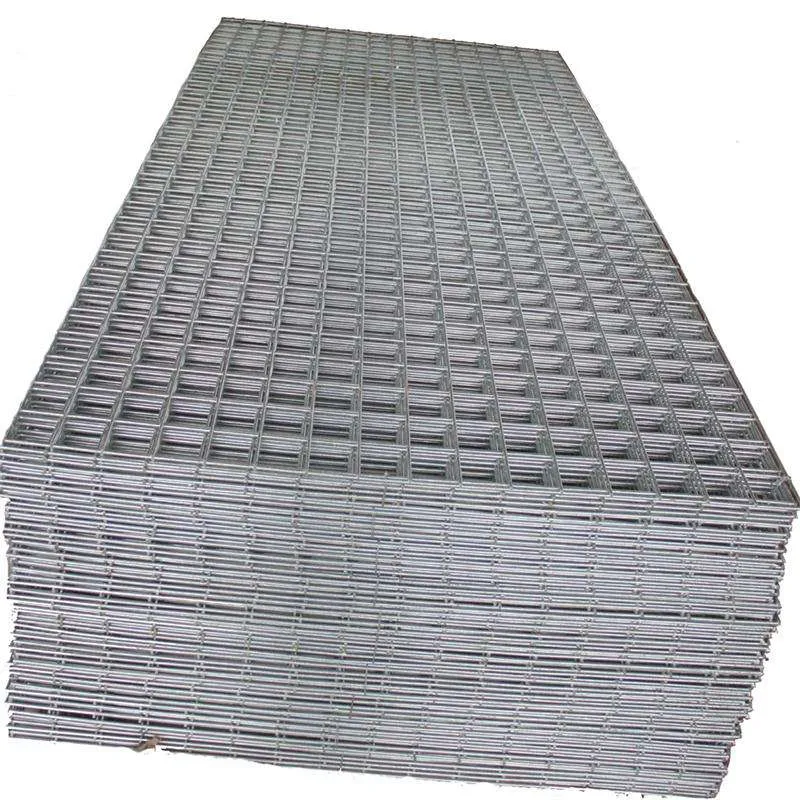

I’ve spent enough time on job sites—and frankly in muddy farm lanes—to know when a product earns its keep. The Hot Dipped Galvanized Welded Mesh Panel is one of those no-drama, shows-up-every-day solutions. It’s not flashy, but when you need rigid barriers that don’t rust away after two rainy seasons, this is what you spec. Many customers say it “just lasts,” and that’s not hype; it’s metallurgy.

Two clear shifts: project owners want longer maintenance cycles (less repainting, less downtime) and faster install. Hot-dip galvanizing ticks both boxes. Surprisingly, we’re also seeing architectural teams using clean, flat welded panels as façade screens and plant trellises—nice crossover from industrial to design. And yes, steel prices wiggle, but demand for long-life perimeter systems hasn’t slowed.

Core material is low‑carbon steel wire, resistance-welded at intersections, then fully hot-dip galvanized after fabrication for total coverage—welds included. That “after-weld” dip is the real hero for corrosion resistance.

| Parameter | Typical Range (≈) | Notes / Testing |

|---|---|---|

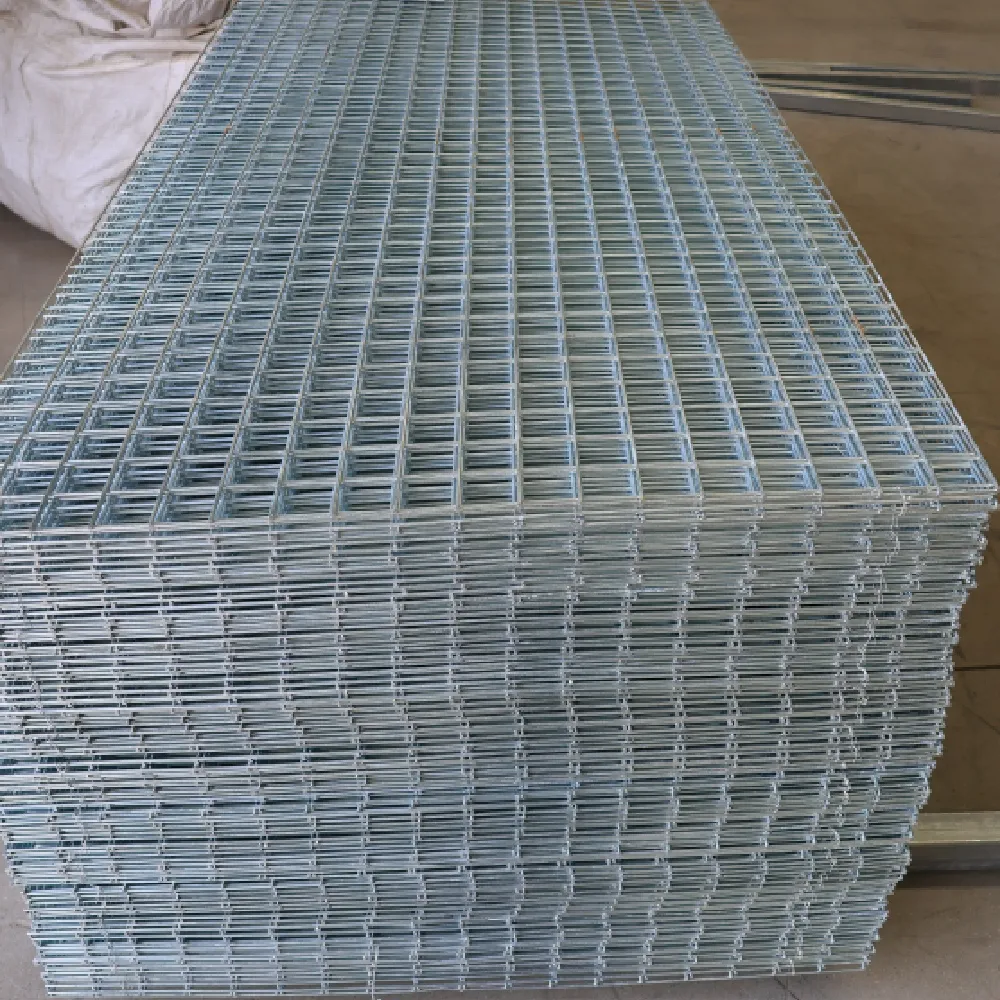

| Wire diameter | 2.5–6.0 mm | Tensile ≈ 380–550 MPa; real-world use may vary |

| Mesh opening | 50×50 to 100×200 mm | Custom grids on request |

| Panel size | 1.0–2.4 m H × 2.0–3.0 m L | Flatness tolerance ≈ ±3 mm/m |

| Zinc coating (avg.) | ≈ 70–100 μm | Meets ASTM A123 / ISO 1461 ranges [1][2] |

| Service life | 20–30 yrs rural; 10–20 yrs urban/coastal | Exposure-dependent; see ISO 9223 guidance |

Recent in-house test set: avg. coating ≈ 610 g/m² (~85 μm) and 720 h neutral salt spray without red rust on the plane—your mileage may vary with cut edges and field handling.

Full post‑weld zinc coverage, consistent flatness, quick clamp or post mounting, and that tough sacrificial Zn layer—so minor scratches don’t become big corrosion headaches. To be honest, the predictability is the selling point.

| Vendor | Zn coating (≈) | Flatness tol. | Lead time | Certifications | Warranty | Price level |

|---|---|---|---|---|---|---|

| Tike Metal (Hebei) | 70–100 μm | ≈ ±3 mm/m | 10–20 days | ISO 9001; ASTM/ISO galvanizing | Up to 10 yrs (env.-dependent) | Mid |

| Vendor B | 50–80 μm | ≈ ±5 mm/m | 15–30 days | ISO 9001 | 5 yrs | Low |

| Vendor C | 80–120 μm | ≈ ±3 mm/m | 20–35 days | ISO 9001/14001 | 8 yrs | High |

Pro tip: ask for coating mass test reports and ISO 9227 salt spray data. It sounds nerdy—because it is—but it saves you later.

Hot Dipped Galvanized Welded Mesh Panel options: mesh aperture, wire gauge, panel size, edges (cut vs. bent), powder topcoat for color, and bracket kits. Origin: East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui City, Hebei Province—yes, right in the heart of China’s wire mesh belt.

Case study 1: 14 km solar farm fence, coastal zone—spec’d 4.0 mm wire, 75×150 mm mesh, ~90 μm Zn; still clean after 3 salty winters. Case study 2: food plant partitions—powder topcoat over zinc for washdown; zero rust complaints after 18 months. Customers mention easy alignment and no panel “oil-canning.”

Common package includes ISO 9001 quality system, material heat numbers, galvanizing certificates to ASTM A123 / ISO 1461, and optional third-party salt spray (ISO 9227). Ask for weld shear test data if you’re doing safety-critical guarding.

References

RELATED PRODUCTS