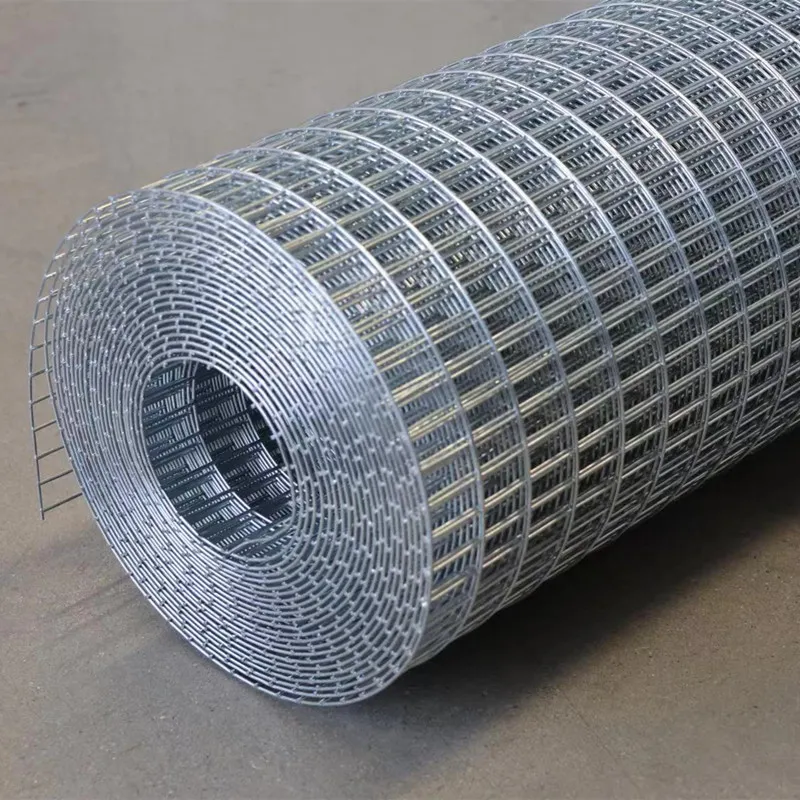

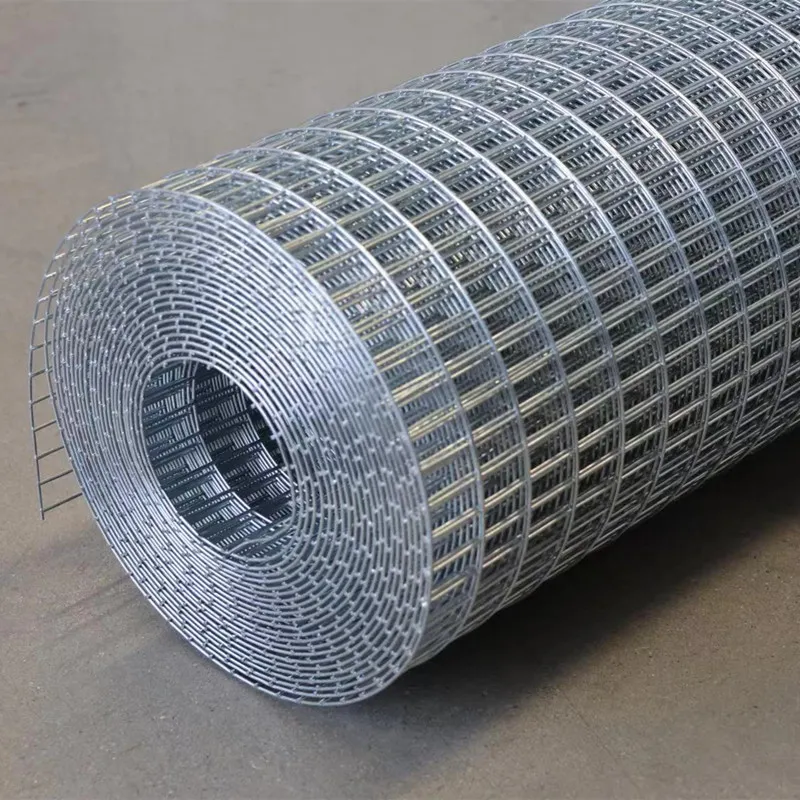

Iron and wire, when combined, form the backbone of countless structural and artistic designs, offering a unique blend of strength and versatility. This pair is not just essential in industrial settings but also bears significance in a range of domestic applications. From fencing solutions to artistic installations, iron and wire have woven themselves into our everyday lives, making them indispensable.

In the realm of experience, users of iron and wire products often commend their durability and reliability. These materials have been the preferred choice for constructing robust and long-lasting fences, trellises, and garden decorative elements. For instance, iron and wire fences are renowned for their ability to withstand harsh weather conditions, offering security without compromising on aesthetics. Customers frequently report that such fences, with minimal maintenance, can last decades while retaining their original charm.

From an expertise perspective, understanding the nuances of working with iron and wire is crucial. These materials, while robust, require a particular skill set to be manipulated effectively. Iron, with its unmatched strength, necessitates tools such as welding machines for assembly, especially in structural applications. Wire, on the other hand, offers flexibility and can be molded with simple pliers. This combination is the reason why artisans and construction experts alike celebrate iron and wire for their adaptability and functionality. For designers, incorporating these materials means calculating load-bearing capacities and ensuring that the chosen gauge of wire complements the iron's density and strength, providing both stability and design aesthetics.

Authoritativeness in the field of iron and wire applications is essential for ensuring safety and efficacy in their use. Industry standards dictate that using galvanized wire with iron structures can prevent corrosion, extending the life of the product. Reputable builders and manufacturers often adhere to these guidelines, providing clients with certified, high-quality materials. Firms that specialize in iron and wire products typically offer warranties and post-installation services, underlining their commitment to safety and customer satisfaction. Such practices not only demonstrate expertise but also solidify a company’s authority in the field.

iron & wire

Trustworthiness is another pivotal consideration when selecting iron and wire products. For consumers, transparency in sourcing materials and manufacturing processes builds confidence. Companies that openly share the origins of their iron and wire, alongside details of their treatment processes like galvanization or powder coating, tend to foster stronger consumer trust. Additionally, feedback from prior customers serves as a credible source of information, further supporting the reliability of the products.

Furthermore, eco-conscious consumers are increasingly drawn to iron and wire for their sustainable properties. Iron, once extracted, can be recycled indefinitely without degradation, while wire made from recycled metals reduces environmental impact. Manufacturers that incorporate sustainable practices into their production processes are not only meeting customer demand but also setting industry standards for ethical manufacturing.

In conclusion, the compelling combination of iron and wire reaches beyond mere functionality, offering users a blend of strength, flexibility, and aesthetic appeal. It takes the convergence of experience, expertise, authoritativeness, and trustworthiness to successfully navigate the selection and application of these materials. Companies that excel in these domains ensure their customers benefit from products that are not only functional and stylish but also dependable and sustainable. Whether for practical or artistic purposes, iron and wire stand out as resilient materials of choice, emboldened by their time-tested reputation and potential for innovation.