Cast iron wire, a material revered for its durability and versatility, has carved its niche in various industrial and domestic applications. From its inception in historical metallurgy to its modern-day utilizations, cast iron wire brings forth a combination of strength, robustness, and functionality. Our deep dive into this material unveils insights that cater to professionals and enthusiasts, ensuring an experience fueled by expertise and trust.

The enduring legacy of cast iron wire is firmly rooted in its exceptional properties. Made from an alloy predominantly composed of iron, carbon, and silicon, cast iron wire is known for its high tensile strength and resistance to wear and oxidation. These properties render it indispensable in environments demanding mechanical reliability and longevity.

In industrial contexts, cast iron wire is a staple. It plays a critical role in construction, manufacturing processes, and even in the creation of artful installations. The construction industry benefits immensely from its use in reinforcing structures, owing to its impressive load-bearing capacities and resistance to environmental stressors. The manufacturing sector relies on cast iron wire for producing durable machining components and fasteners, ensuring the smooth operation of heavy machinery under intense conditions.

Beyond industry, the domestic applications of cast iron wire are equally fascinating. Garden enthusiasts often employ it for constructing resilient fencing and trellises, benefiting from its ability to withstand weather changes without corroding. In the realm of home décor, artists and designers favor cast iron wire for crafting sculptures and decorative items, admired for their aesthetic appeal and structural integrity.

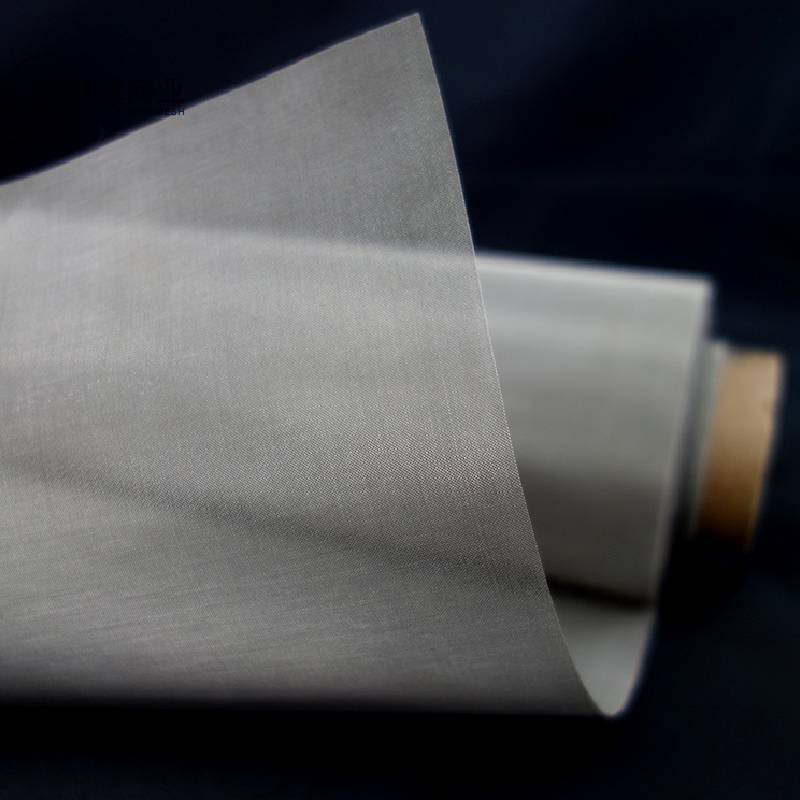

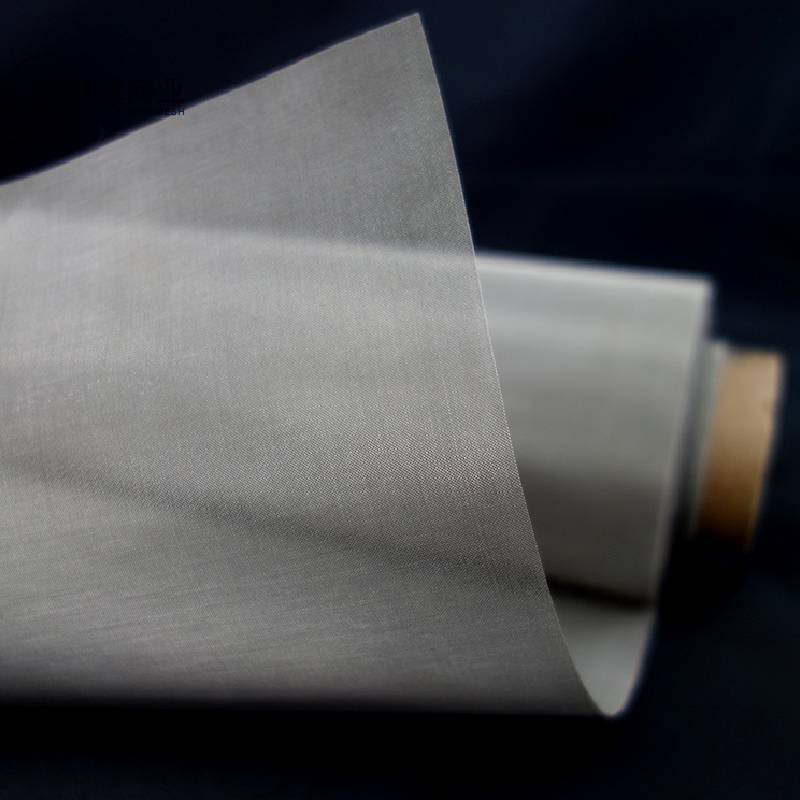

cast iron wire

Understanding the manufacture of cast iron wire further exemplifies its authority in the market. The production process begins with the careful selection of raw materials, which are then melted in a blast furnace. The metamorphosis from molten mixture to solid wire involves state-of-the-art drawing techniques that ensure uniformity and robustness. Quality control is stringent, with every batch undergoing rigorous testing to meet industry standards. This commitment to precision not only speaks to its expertise but also builds a foundation of trust among consumers and businesses alike.

One cannot overlook the ecological considerations when discussing cast iron wire. The production of this material emphasizes sustainability, with manufacturers implementing practices that minimize waste and energy consumption. This eco-friendly approach aligns with modern-day demands for sustainable materials, positioning cast iron wire as a responsible choice in an environmentally conscious market.

The market recognizes the inherent value offered by cast iron wire through its adaptability across various domains. As industries continue to innovate, the demand for reliable materials like cast iron wire only grow stronger, cementing its long-standing authority.

Sharing real-life experiences and case studies further exemplifies its performance and benefits. Stories from construction experts and homeowners alike underscore the reliability and trustworthiness of cast iron wire as a solution-oriented material.

In conclusion, cast iron wire stands out as a multi-faceted material that combines experience, expertise, authority, and trustworthiness. Its timeless appeal and functionality ensure its place in both contemporary and future applications. Whether you are an industry professional seeking reliable materials or an enthusiast exploring robust options, cast iron wire offers unparalleled advantages that resonate with these core values.