Galvanized steel grating stands as a pillar in the industrial and commercial sectors due to its robust nature and versatile applications. It is imperative, especially in today's competitive marketplace, to understand the intricacies tied to its pricing. This knowledge not only aids in making informed purchases but also ensures long-term satisfaction and utility.

The pricing of galvanized steel grating is influenced by a range of factors, each contributing significantly to its final cost. Raw material prices play a critical role, with the fluctuation in the steel market impacting overall expenses. The galvanization process itself, which includes the coating of steel with a protective layer of zinc to resist corrosion and extend lifespan, incurs additional costs. The thickness of the zinc coating often directly correlates to price variations; thicker coatings offer enhanced durability and thus command higher prices.

Manufacturing processes can also affect pricing. Advanced technologies that ensure precision and superior quality may increase initial costs but result in a long-lasting product that provides greater value over time. It's important to assess whether manufacturers have certifications and a proven track record of producing grating according to industry standards, as this ensures quality and reliability.

Size and specification of the grating are other key determinants. Larger or custom-sized grates may require more material and labor, thus driving up prices. Similarly, specific load requirements, such as those for heavy-duty applications, necessitate the use of thicker materials and more stringent manufacturing standards, impacting the cost.

When evaluating prices, geographic location can't be ignored. Local market conditions, including supply chain logistics, local taxes, and import duties, can all influence cost. Proximity to manufacturing facilities can reduce transportation costs, making regional procurement an economically sound decision.

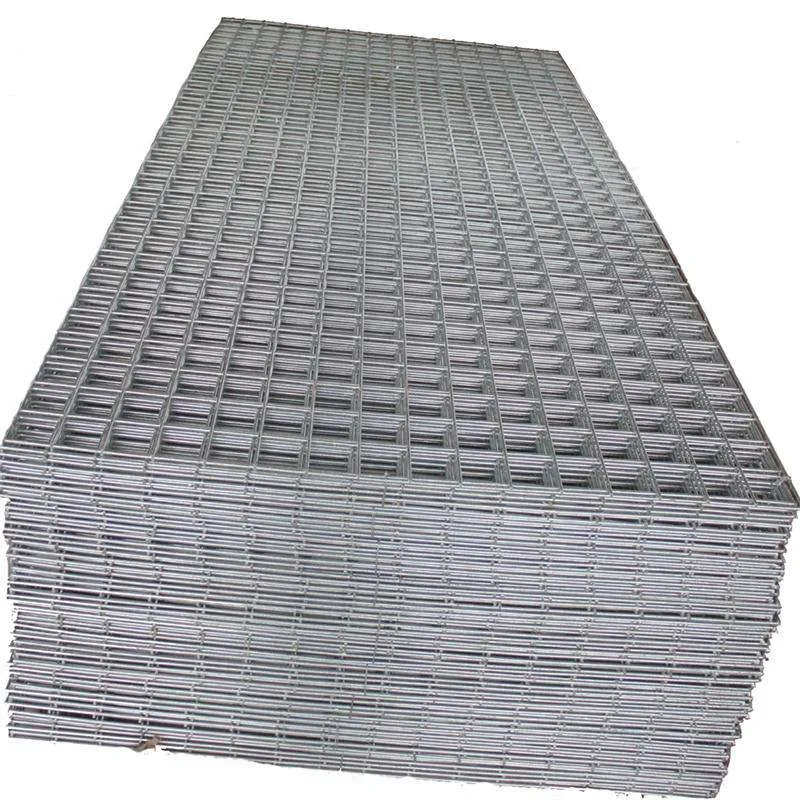

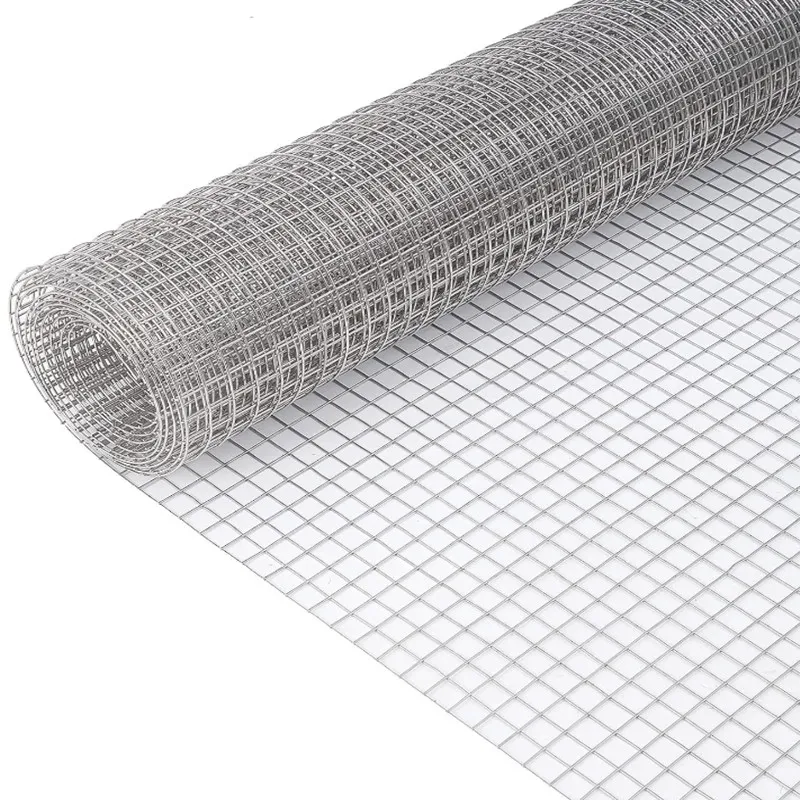

galvanized steel grating prices

In addition to understanding baseline costs, potential buyers should consider value-added services offered by suppliers, such as custom fabrication, cutting, or additional coatings for specialized purposes. While these may increase upfront expenses, they contribute significantly to the product’s longevity and utility.

To ensure compatibility and adequacy for specific projects, consulting with industry professionals can provide insight into the most suitable types of galvanized steel grating for particular applications. Engineering consultations can often lead to the selection of the most cost-effective and durable solution, aiding in navigating the complex pricing landscape.

In the digital age, leveraging online platforms to compare prices and read reviews has become an invaluable tool. However, it’s vital to distinguish between pure price competition and suppliers that offer comprehensive support and a commitment to quality. Establishing a relationship with a trusted supplier that balances competitive pricing with exceptional customer service ensures not just cost savings, but also peace of mind.

Ultimately, while price is a critical factor, it should not overshadow the essential attributes of quality, durability, and the specific requirements of a project. Investing in high-quality galvanized steel grating can lead to notable long-term savings, reduced maintenance costs, and increased safety in industrial applications.

Maintaining an awareness of market trends and establishing relationships with reputable suppliers are key strategies for effectively managing costs associated with galvanized steel grating. Continuous learning and adaptation to new technologies and processes will not only keep your operations competitive but also secure in the ever-evolving market landscape.