Navigating the Cost of Steel Grating An Insightful Exploration

Steel grating stands as an indispensable component in industrial and commercial construction projects, renowned for its durability, strength, and adaptability. However, the cost associated with steel grating can often be a point of contention, prompting a need for an informed perspective to assist in making economically sound decisions. This article delves into the nuanced factors influencing the cost of steel grating, providing a blend of real-world experience, industry expertise, authoritative insights, and trustworthy guidance.

Understanding the Cost Components

The cost of steel grating isn't merely a number on a price list; it is a composite of various elements that collectively determine the final price.

The type of steel used is a primary factor. Carbon steel grating usually represents the most cost-effective option, being less expensive than stainless steel or aluminum alternatives. The choice between these materials influences not just the upfront cost but also considerations for longevity and maintenance.

Another significant factor is the manufacturing process. The two predominant methods—welded and press-locked grating—have different cost implications. Welded grating, where steel bars are fused under heat and pressure, often costs more due to the intensive labor and machinery involved. Conversely, press-locked grating, where bars are mechanically interlocked, may offer a more budget-friendly solution.

Dimensions and Customization

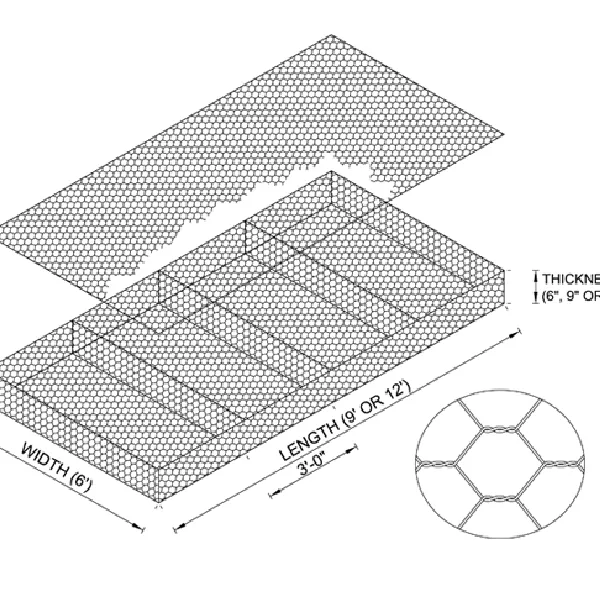

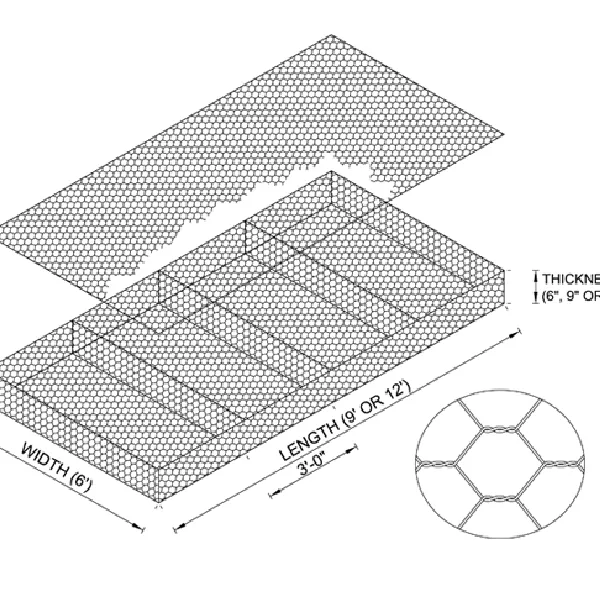

Customization is key in many industrial applications, and with customization comes added cost. The size of the panels, the load-bearing requirements, and specific design features like serrations for increased slip resistance influence pricing. These features are critical to meeting specific safety codes and operational needs, which justifies their additional expense.

Experience from industry veterans highlights that ordering standard sizes and configurations can significantly reduce costs, as these are often produced in bulk and do not require specialized tooling or processing. However, while upfront savings are attractive, ensuring that the grating meets all necessary operational requirements should always take precedence.

cost of steel grating

Market Fluctuations

Steel is a globally traded commodity, making its price susceptible to market fluctuations. Supply chain dynamics, global steel production rates, trade tariffs, and geopolitical factors can all influence prices. For instance, during times of supply shortages or increased demand, prices typically rise. Industry experts recommend keeping an eye on market trends and locking in prices when they are favorable to mitigate unexpected budget increases.

Moreover, larger projects might benefit from strategic partnerships with suppliers who can offer insights and pricing forecasts. Establishing such relationships can help secure more stable pricing over longer periods, providing project managers with better control over budget allocations.

Authoritative Insights on Lifecycle Costs

It's crucial to consider not just the initial cost but the lifecycle cost of steel grating. Stainless steel grating, although more expensive initially, offers superior corrosion resistance, which translates into lower maintenance and replacement costs over time. Experts advocate for a comprehensive cost analysis that projects future expenses related to upkeep and potential replacements, especially in industries where corrosive elements are prevalent.

Trustworthiness and Supplier Selection

Selecting a reputable supplier is paramount to ensuring quality and cost-effectiveness. Trustworthy suppliers offer transparent pricing, detailed specifications, and support services such as delivery logistics and installation guidance. Looking at customer reviews, industry certifications, and establishing communication with suppliers can significantly enhance trust and ensure that the purchase decision is sound.

In conclusion, understanding the multifaceted nature of steel grating costs allows stakeholders to make informed purchasing decisions. By considering material types, manufacturing processes, customization needs, and market trends, alongside establishing reliable supplier relationships, it is possible to balance cost with quality efficiently. Through strategic planning and informed decision-making, steel grating purchases can be optimized for both immediate and long-term benefits.