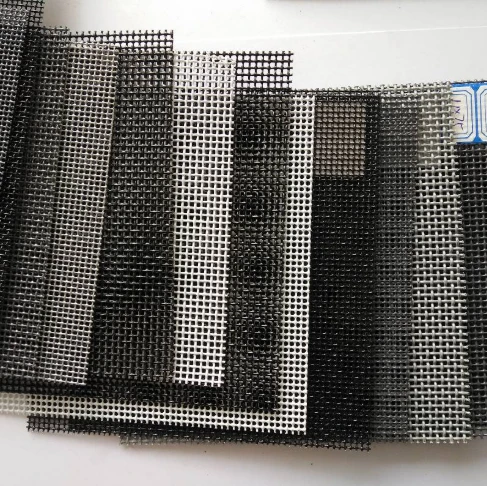

(coated expanded metal mesh)

Coated expanded metal mesh combines durability with adaptability, making it a preferred choice across industries. Unlike standard metal sheets, this material undergoes a precision expansion process followed by specialized coating treatments—such as powder coating or galvanization—to enhance corrosion resistance and longevity. Recent market data indicates a 12% annual growth in demand for coated variants, driven by their ability to withstand harsh environments while maintaining structural integrity.

When compared to uncoated expanded metal or welded wire mesh, coated versions deliver superior performance. Key benefits include:

Independent tests show powder coated expanded metal retains 98% of its tensile strength after 5,000 hours of salt spray exposure.

| Manufacturer | Coating Type | Thickness Range | Price per m² (USD) |

|---|---|---|---|

| MetalTex Solutions | Polyester Powder | 0.8-3.0mm | $28-$75 |

| ExpandCoat Inc. | Epoxy Hybrid | 1.2-4.5mm | $35-$92 |

| DuraMesh Pro | Galvanized + PVC | 1.0-5.0mm | $41-$110 |

Advanced coating technologies enable tailored solutions:

Recent projects have demonstrated 40% faster installation times with pre-coated modular panels compared to onsite treatment methods.

A coastal infrastructure project utilized aluminum expanded mesh with fluoropolymer coating, achieving:

Lifecycle analysis reveals:

The global coated metal mesh market is projected to reach $2.8 billion by 2028, driven by smart manufacturing integration. Emerging technologies like nano-ceramic coatings and automated coating verification systems are setting new benchmarks for quality control, ensuring consistent performance across production batches while reducing material waste by 18%.

(coated expanded metal mesh)

A: Coated expanded metal mesh offers enhanced durability, corrosion resistance, and aesthetic appeal. The coating (e.g., PVC or polymer) protects against harsh weather and chemicals. It’s ideal for outdoor and industrial applications.

A: Powder coating provides a thicker, more uniform protective layer compared to liquid coatings. It’s eco-friendly, chip-resistant, and available in diverse colors. This makes it suitable for architectural and decorative uses.

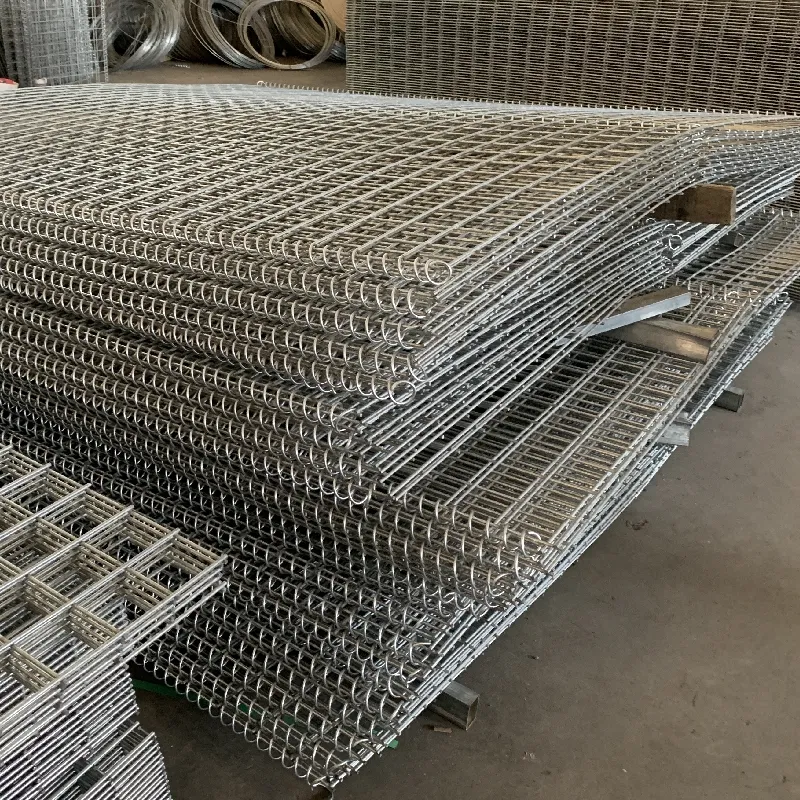

A: Yes, coated metal mesh is often used in fencing, enclosures, and barriers due to its strength and anti-rust properties. The coating adds an extra layer of protection while maintaining visibility and airflow.

A: Coatings are typically applied to steel, aluminum, or stainless steel expanded metal. The base material determines strength, while coatings enhance performance in specific environments (e.g., marine or chemical settings).

A: Powder coated expanded metal requires minimal maintenance. Regular cleaning with mild soap and water preserves its appearance. The coating resists fading, peeling, and abrasion under normal conditions.

RELATED PRODUCTS