(steel grating panels)

Steel grating panels have become indispensable in industrial and architectural projects, offering a unique combination of strength (load capacities up to 12,000 lbs/ft²) and permeability. Recent market data shows a 17% annual growth in stainless steel welded panel adoption, driven by their 40-year lifespan in corrosive environments. Modern manufacturing techniques now enable 15% lighter panels without compromising structural integrity.

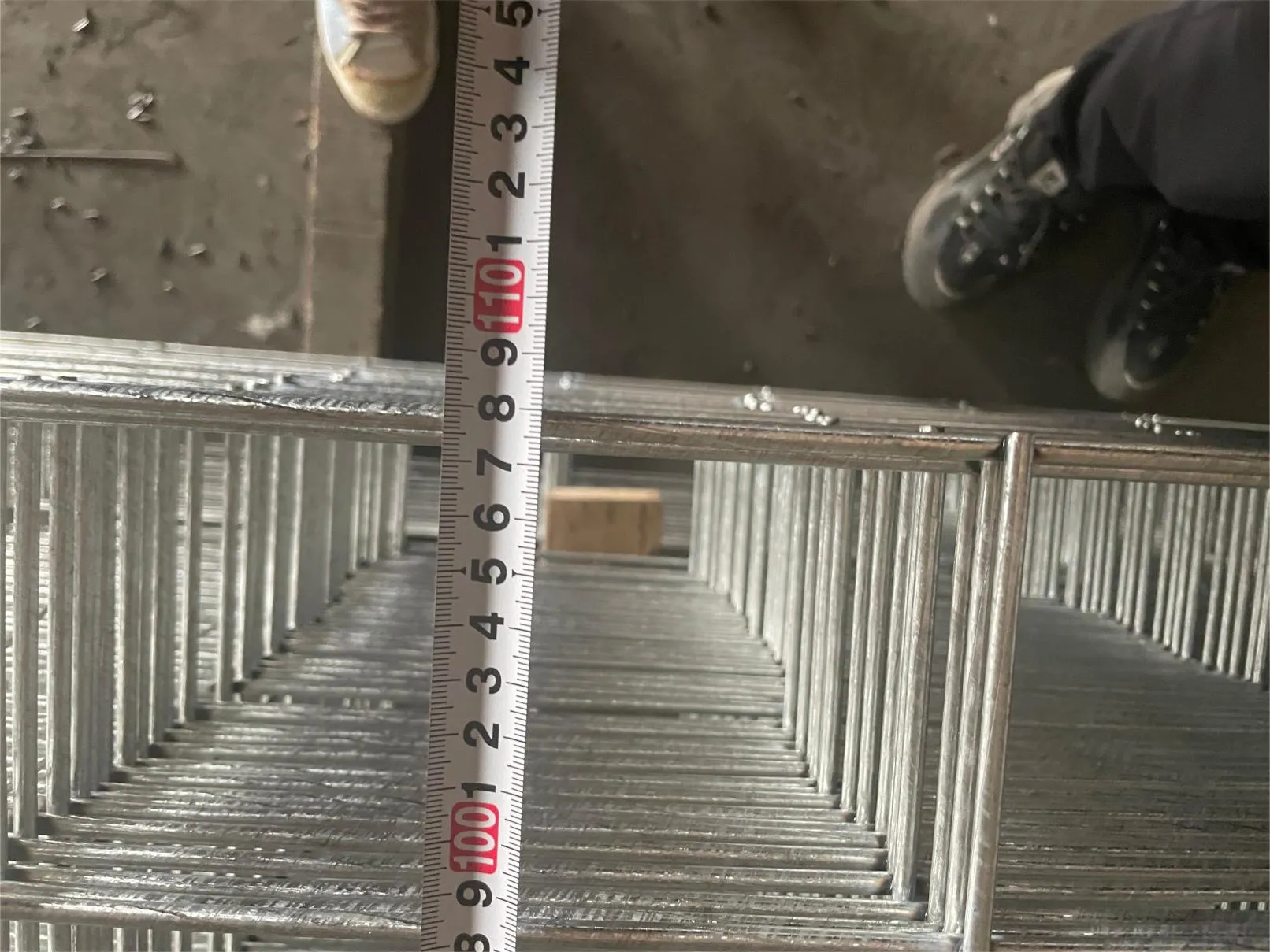

Advanced production methods yield panels with 0.5-6mm strand thickness and 12-100mm bearing bar spacing. Stainless steel mesh fence panels demonstrate 98% resistance to salt spray corrosion (ASTM B117 standards), outperforming galvanized alternatives by 300%. Laser-welded joints increase panel stability by 22% compared to traditional press-lock systems.

| Manufacturer | Product Type | Max Load (lbs/ft²) | Corrosion Rating | Warranty |

|---|---|---|---|---|

| ABC Steel | Stainless Welded | 10,500 | Class 4 | 25 years |

| XYZ Grating | Heavy-Duty Mesh | 12,200 | Class 5 | 30 years |

| PQR Fabrication | Custom Fence Panels | 8,750 | Class 3 | 20 years |

Tailored configurations account for 35% of current orders, with options including:

A coastal refinery project utilized 2,800m² of stainless steel welded panels, reducing maintenance costs by 60% over five years. In a recent transportation hub upgrade, custom-sized steel grating panels

with 30mm spacing improved drainage efficiency by 45% while maintaining ADA compliance.

Proper anchoring increases load distribution efficiency by 18-22%. Field data shows that using neoprene pads between panels and supports extends service life by 40% in high-vibration applications. Annual inspection protocols can identify 92% of potential fatigue issues before failure occurs.

Next-generation steel grating panels now incorporate IoT-enabled strain sensors for real-time structural monitoring. Industry forecasts predict a 29% increase in demand for hybrid stainless steel mesh fence panels with integrated security features by 2028. These innovations maintain the core benefits of traditional steel grating solutions while addressing modern infrastructure challenges.

(steel grating panels)

A: Steel grating panels are widely used for industrial platforms, walkways, and drainage covers due to their durability, slip resistance, and high load-bearing capacity. They are ideal for environments requiring ventilation and debris drainage.

A: Stainless steel welded panels are corrosion-resistant and welded for seamless strength, making them suitable for harsh environments. Standard steel grating panels may require coatings for similar durability but are more cost-effective for general use.

A: Yes, stainless steel mesh fence panels can be tailored with tighter mesh patterns or reinforced frames for enhanced security. Their corrosion resistance also ensures longevity in outdoor settings.

A: Yes, but stainless steel welded panels are recommended for coastal areas due to their superior resistance to saltwater corrosion. Standard steel grating panels may require galvanization for added protection.

A: The decision depends on load requirements, exposure to corrosive elements, and aesthetics. Steel grating panels excel in heavy-duty settings, while stainless steel mesh offers lightweight security and modern appeal.

RELATED PRODUCTS