Introduction to Precision Engineered Square Wire Mesh

In the realm of industrial filtration, screening, and structural reinforcement, the demand for materials exhibiting exceptional precision, durability, and versatility is paramount. Square wire mesh stands as a cornerstone product, meticulously engineered to meet the rigorous requirements of diverse B2B applications. Its defining characteristic – uniformly sized square apertures – ensures consistent filtration and separation efficiency, making it an indispensable component across numerous heavy industries.

This comprehensive overview delves into the intricate world of square wire mesh, exploring its manufacturing excellence, technical specifications, multifaceted application scenarios, and the inherent advantages it offers. We will also address critical aspects such as quality assurance, customization, and after-sales support, providing decision-makers with a holistic understanding of this vital industrial material.

Industry Trends and Market Dynamics

The market for square wire mesh is currently experiencing robust growth, driven by escalating demands in infrastructure development, environmental protection technologies, and the expansion of the manufacturing sector. Key trends indicate a shift towards:

- Advanced Materials: Increasing adoption of specialty alloys, such as Duplex Stainless Steel, Super Duplex Stainless Steel, and high-nickel alloys, for enhanced corrosion resistance and performance in extreme conditions.

- Finer Meshes and Higher Precision: A growing need for finer filtration and separation, particularly in chemical processing, pharmaceuticals, and precision engineering, necessitating meshes with increasingly smaller aperture sizes and tighter tolerances.

- Sustainability Focus: Demand for materials that contribute to energy efficiency and waste reduction in industrial processes, where optimized flow and separation can significantly reduce operational costs and environmental impact.

- Customization and Integration: A rising preference for custom-fabricated mesh components that integrate seamlessly into complex industrial systems, often requiring specific dimensions, edge treatments, or secondary processing.

Projections suggest the global industrial filtration market, a primary consumer of square wire mesh, will grow at a CAGR of approximately 6% from 2023 to 2030, reflecting sustained demand for high-performance separation media. (Source: Grand View Research, 2023)

Manufacturing Process Flow of Square Wire Mesh

The production of high-quality Square wire mesh involves a meticulously controlled multi-stage process, ensuring product integrity and performance. Our manufacturing adheres to stringent quality protocols, from material selection to final inspection.

1. Material Selection & Preparation:

We utilize premium-grade materials, including various stainless steel alloys (304, 304L, 316, 316L, 310S, 321), high-performance nickel alloys (Inconel, Monel, Hastelloy), titanium, and other specialized metals. These are sourced from certified suppliers, ensuring chemical composition and mechanical properties meet international standards (e.g., ASTM A276/A479 for stainless steels). Wires are typically drawn to precise diameters, ranging from 0.025 mm to 10 mm, depending on the mesh specification.

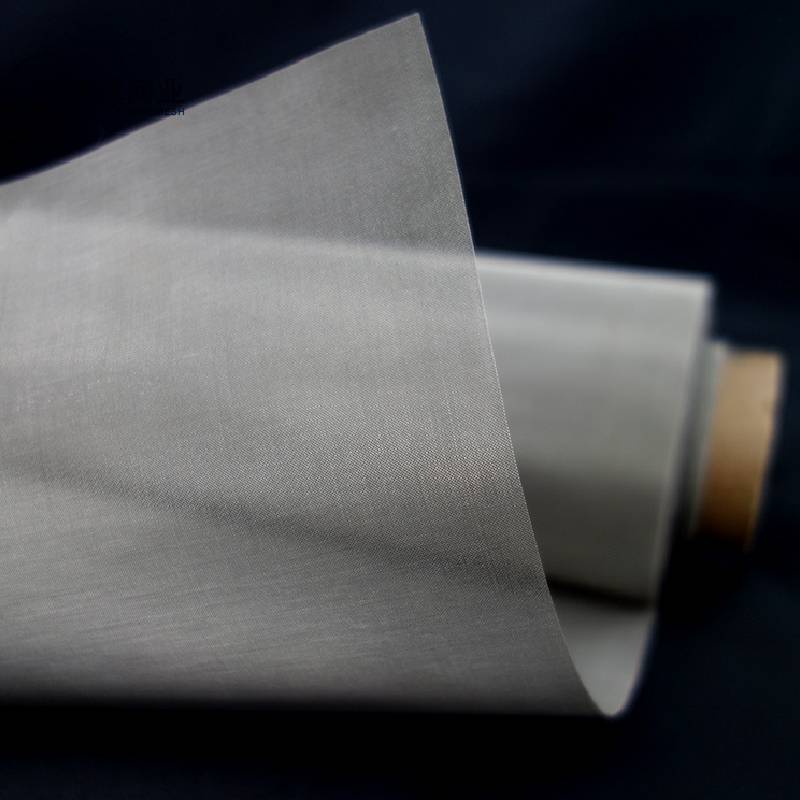

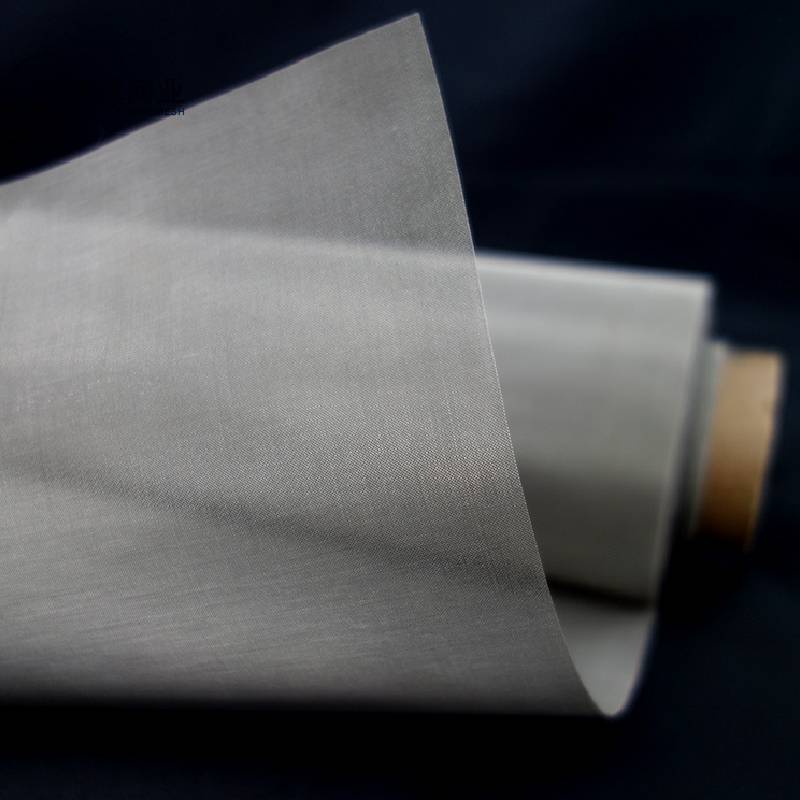

2. Weaving Process:

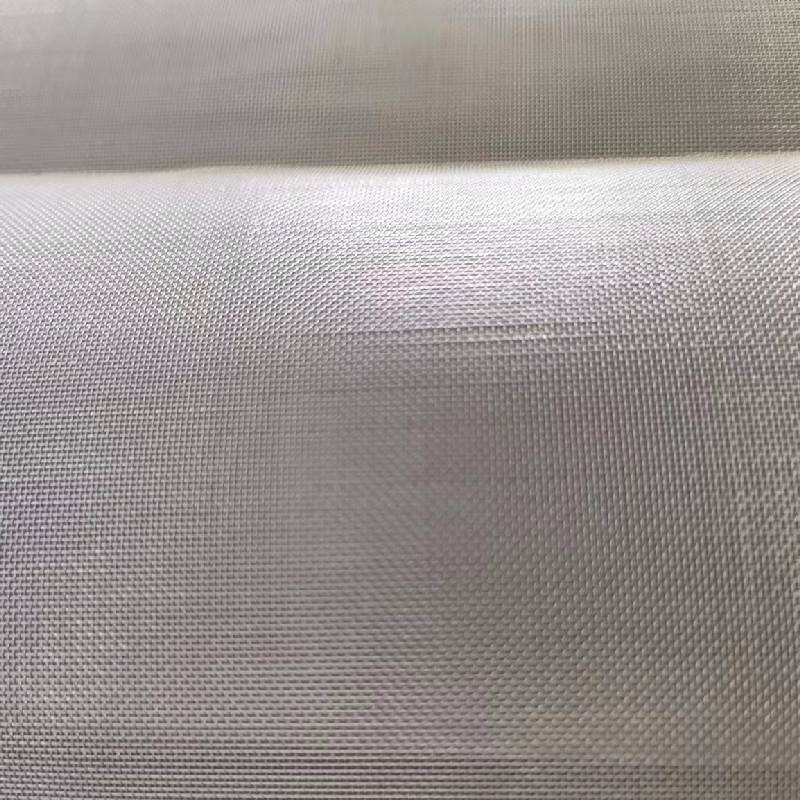

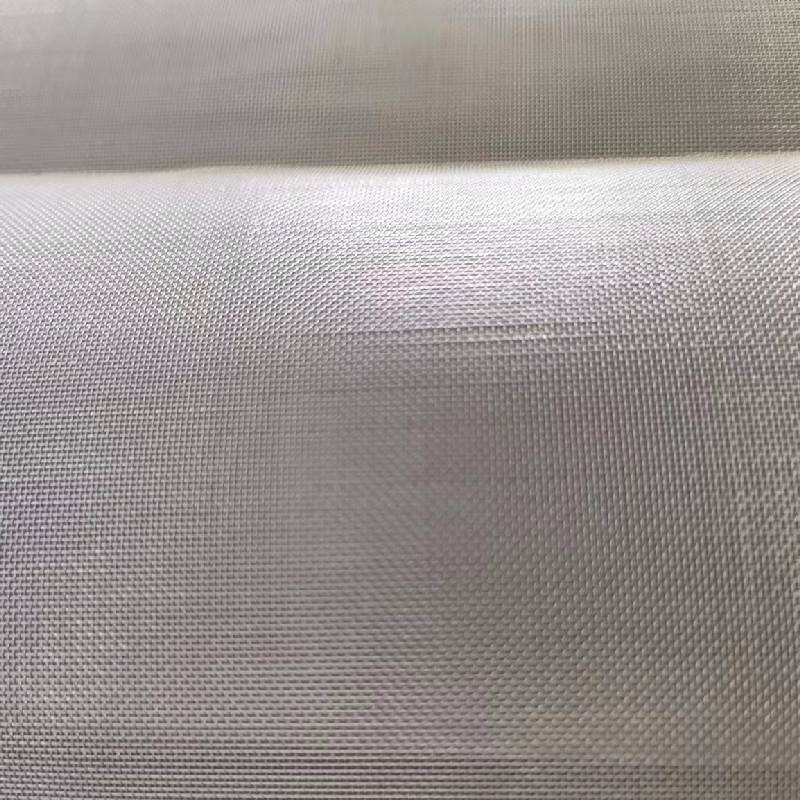

The core of Square wire mesh fabrication is the weaving operation. Our advanced looms employ a plain weave pattern, where each weft wire passes alternately over and under each warp wire, and each warp wire passes alternately over and under each weft wire. This fundamental weave structure creates the characteristic square apertures, providing excellent stability and open area. Precision control of tension and wire spacing during weaving is crucial for maintaining mesh consistency and aperture accuracy.

3. Finishing & Treatment:

Post-weaving, the mesh undergoes several finishing processes. These may include:

- Cleaning: Removal of lubricants, oils, and other contaminants from the weaving process.

- Annealing (Heat Treatment): For certain materials, annealing may be performed to relieve stress induced during wire drawing and weaving, enhancing ductility and formability.

- Edge Treatment: Options include raw edges, selvaged edges, or folded/welded edges for specific applications, preventing fraying and ensuring safe handling.

- Cutting & Fabrication: Utilizing CNC machining for precise cutting into panels, discs, or other custom shapes as per client specifications. Advanced laser cutting or waterjet cutting ensures clean, burr-free edges without material distortion.

4. Quality Control & Testing:

Every batch of Square wire mesh undergoes rigorous testing to ensure compliance with quality standards such as ISO 9044:2000 (Industrial wire screens — Guide to the choice of aperture size and wire diameter combinations) and ANSI/AWWA B300 (standard for sampling and testing of aggregates). Key tests include:

- Aperture Size Measurement: Optical micrometers and calibrated gauges ensure precise and uniform mesh opening.

- Wire Diameter Verification: Calipers and micrometers confirm wire gauge accuracy.

- Tensile Strength & Elongation: Mechanical testing to verify the mesh's structural integrity.

- Corrosion Resistance Tests: Salt spray tests or immersion tests for materials designated for corrosive environments.

- Visual Inspection: Examination for weaving defects, wire damage, or surface imperfections.

The average service life of our square wire mesh varies significantly based on material and application, ranging from 5-10 years for standard stainless steel in benign environments to over 20 years for specialty alloys in demanding, high-corrosion or high-temperature applications.

Technical Specifications and Performance Parameters

The performance of Square wire mesh is defined by several critical technical parameters that dictate its suitability for specific industrial applications. Understanding these specifications is essential for optimal material selection and process efficiency.

Table 1: Common Square Wire Mesh Specifications (Illustrative Range)

| Parameter |

Typical Range |

Unit |

Description |

| Mesh Count |

2 to 635 |

meshes/inch (or 1 to 250 meshes/cm) |

Number of openings per linear inch (or cm). Higher count means finer mesh. |

| Wire Diameter |

0.025 to 10.0 |

mm |

Diameter of the individual wires. Influences strength and open area. |

| Aperture Size |

0.02 to 12.0 |

mm |

Dimension of the clear opening between adjacent wires. Determines particle size separation. |

| Open Area |

2% to 90% |

% |

Percentage of the total mesh area that is open. Affects flow rate and screening efficiency. |

| Material Grades |

SS304, SS316, SS310S, Hastelloy, Monel, Titanium, Galvanized Steel |

N/A |

Chemical composition determining corrosion resistance, strength, and temperature limits. |

| Roll Width |

0.5 to 2.0 |

meters |

Standard width of woven mesh rolls for ease of handling and fabrication. |

These parameters are interconnected. For instance, a finer mesh count typically implies a smaller wire diameter and aperture size, leading to a lower open area. The choice of material is critical; for example, SS316L offers superior corrosion resistance in chloride environments compared to SS304, making it ideal for marine or chemical processing applications.

Application Scenarios and Industry Use

The intrinsic properties of Square wire mesh – uniform apertures, robust construction, and material versatility – make it indispensable across a spectrum of target industries and critical application scenarios.

1. Petrochemical Industry:

In petrochemical refining and processing, square wire mesh is extensively used for catalyst support grids, molecular sieve retainers, and general filtration in severe environments involving corrosive chemicals and high temperatures. Its inherent corrosion resistance (especially in Hastelloy or Inconel alloys) ensures structural integrity and process reliability, significantly extending the service life of filtration units and reducing downtime for maintenance. This translates directly to enhanced energy saving by optimizing flow dynamics and preventing premature equipment degradation.

2. Metallurgy and Mining:

For mineral sizing, aggregate screening, and dewatering, square wire mesh serves as critical screening media in vibrating screens and trommels. Its abrasion resistance and high tensile strength, particularly in high-carbon steel or manganese steel variants, ensure durability against aggressive abrasive materials, leading to consistent product quality and reduced operational wear and tear. In scenarios like coal washing or ore separation, the precise aperture of the mesh ensures efficient classification, minimizing material loss.

3. Water Supply & Drainage:

In municipal and industrial water treatment plants, square wire mesh is deployed in intake screens, clarifier baffles, and filter underdrains. Stainless steel grades (e.g., SS316L) provide excellent corrosion resistance against treated water and various contaminants, ensuring long-term performance and minimizing the need for frequent replacement. Its robust structure withstands continuous flow and pressure, contributing to efficient particulate removal and maintaining water quality standards. This directly impacts environmental compliance and public health.

4. Food & Beverage Processing:

For processes requiring hygienic separation and sifting, such as grain cleaning, fruit washing, and brewing filtration, square wire mesh made from food-grade stainless steel (e.g., SS304, SS316) is essential. Its smooth, non-porous surface facilitates easy cleaning and prevents bacterial growth, adhering to strict FDA and HACCP guidelines. This ensures product purity and safety, vital for consumer confidence and regulatory compliance.

These diverse applications underscore the adaptive nature and critical importance of high-quality square wire mesh in supporting efficient, safe, and sustainable industrial operations.

Technical Advantages of Square Wire Mesh

The geometric configuration and material properties of square wire mesh confer several distinct technical advantages that are critical for B2B applications:

- Unmatched Filtration Precision: The consistent and uniformly sized square apertures provide precise and predictable particle separation. This is crucial for applications requiring exact classification, such as in laboratory sieves, pharmaceutical processes, and fine chemical filtration, where deviation can lead to product contamination or quality compromise.

- Superior Open Area and Flow Rate: Compared to other mesh types (e.g., Dutch weave), plain woven square mesh often offers a higher open area for a given mesh count and wire diameter. This maximizes flow rate and minimizes pressure drop, leading to energy savings in pumping and increased throughput in screening and filtration systems.

- Exceptional Structural Stability: The robust plain weave construction ensures excellent structural integrity and dimensional stability. This resistance to deformation under load or vibration makes it ideal for heavy-duty screening, support grids, and reinforcement applications, prolonging the operational lifespan of equipment.

- Versatile Material Compatibility: Available in a vast array of materials—from various grades of stainless steel (SS304, SS316, SS310S) to specialty alloys like Monel, Hastelloy, and Inconel, as well as non-ferrous metals like copper and brass—square wire mesh can be tailored to withstand extreme temperatures, corrosive chemicals, and abrasive environments, ensuring optimal performance and longevity.

- Ease of Fabrication and Cleaning: The inherent flatness and rigidity of square wire mesh simplify fabrication into custom shapes, discs, cylinders, or panels. Its relatively smooth surface also facilitates efficient cleaning and backwashing, which is vital for maintaining filtration efficiency and hygiene, particularly in food and pharmaceutical industries.

These advantages collectively position Square wire mesh as a cost-effective and high-performance solution for demanding industrial filtration, separation, and structural applications, contributing to operational efficiency and product quality.

Vendor Comparison and Selection Criteria

Selecting the right vendor for Square wire mesh is a critical decision that impacts product quality, operational efficiency, and long-term cost of ownership. Beyond initial price, B2B purchasers should evaluate vendors based on a comprehensive set of criteria.

Table 2: Vendor Comparison Factors for Square Wire Mesh

| Feature/Criteria |

Vendor A (Example: General Supplier) |

Vendor B (Example: Specialist Manufacturer) |

| Material Range |

Common Stainless Steel (304, 316), Galvanized |

Extensive: SS (304, 304L, 316, 316L, 310S, 321), Hastelloy, Monel, Inconel, Titanium, Copper Alloys |

| Customization Capability |

Limited to standard cuts and dimensions |

Full range: bespoke mesh counts, wire diameters, specialized alloys, fabrication (discs, cylinders, custom frames), advanced edge treatments (welding, folding) |

| Quality Certifications |

Basic ISO 9001 (for distribution) |

ISO 9001 (manufacturing), Material Test Certificates (MTCs), compliance with ASTM, DIN, JIS standards; often FDA-compliant materials. |

| Technical Support |

Standard product information |

Application engineering support, material selection guidance, performance simulation, post-installation troubleshooting. |

| Lead Time for Custom Orders |

Longer, less predictable (subcontracted fabrication) |

Shorter, more predictable (in-house design & manufacturing) |

| Pricing Structure |

Often lowest for standard products, higher for complex items |

Competitive for standard, value-driven for specialty/custom, justified by quality and longevity |

Choosing a specialist manufacturer like Tikemetal ensures access to a broader material portfolio, advanced fabrication capabilities, stringent quality control, and expert technical support—all vital for optimizing system performance and reducing total cost of ownership in demanding industrial applications.

Customized Solutions for Square Wire Mesh

Recognizing that off-the-shelf solutions rarely meet the precise requirements of complex industrial processes, we offer extensive customization options for our square wire mesh. Our engineering team collaborates closely with clients to develop tailor-made products that perfectly integrate into existing systems and optimize performance.

Customization capabilities include:

- Bespoke Mesh Specifications: Precision control over mesh count, wire diameter, and aperture size to meet specific filtration or screening cut points.

- Specialty Material Selection: Sourcing and weaving exotic alloys (e.g., Titanium, Zirconium, high-temperature alloys) for extreme chemical, thermal, or pressure environments.

- Advanced Fabrication: Offering precision cutting, slitting, forming, welding, and soldering services to produce mesh filters, baskets, strainers, sieves, or architectural panels. This includes plasma, laser, and waterjet cutting for intricate shapes with minimal material distortion.

- Surface Treatments: Applying electropolishing for enhanced corrosion resistance and improved cleanability, or specialized coatings for anti-fouling or non-stick properties.

- Integrated Components: Manufacturing mesh components with reinforced frames, flanges, or sealing elements for seamless installation and optimal functionality within filtration systems.

Our design and manufacturing flexibility ensures that clients receive a square wire mesh solution that is not only fit-for-purpose but also optimized for long-term performance and cost-efficiency.

Application Case Studies

Real-world implementations demonstrate the transformative impact of precisely engineered square wire mesh solutions:

Case Study 1: Enhanced Filtration in a Chemical Processing Plant

A leading chemical manufacturer faced challenges with inconsistent product purity and frequent clogging of their existing filtration system for a corrosive organic solvent. The existing mesh lacked the required corrosion resistance and aperture precision. We designed and supplied custom-fabricated Square wire mesh filter elements using Hastelloy C-276, with a precise 200 mesh count and 0.05mm wire diameter.

- Outcome: The new Hastelloy mesh dramatically improved filtration efficiency, reducing impurities by 95% and extending filter element lifespan by over 300%. This resulted in a 15% reduction in operational costs due to less frequent filter changes and a significant improvement in final product quality, meeting stringent industry standards.

Case Study 2: Optimized Screening in Mining Operations

A large-scale copper mine experienced high wear rates and premature failure of their vibrating screen meshes during ore classification. The abrasive nature of the ore and continuous impact caused frequent mesh replacement, leading to considerable downtime. We collaborated to develop heavy-duty square wire mesh panels using high-tensile, abrasion-resistant manganese steel (ASTM A128), specifically engineered with larger wire diameters and appropriate open areas for optimal performance in coarse screening applications.

- Outcome: The specialized manganese steel square wire mesh panels demonstrated a 2.5x increase in service life compared to previous solutions. This translated to a 20% reduction in annual maintenance costs and a 10% increase in overall plant throughput due to minimized downtime and consistent screening efficiency.

Case Study 3: Advanced Water Treatment for a Municipal Plant

A municipal water treatment facility required an upgrade to its intake screens to prevent large debris from entering the treatment process while ensuring minimal flow restriction. Existing screens were prone to corrosion and difficult to clean. We provided custom-sized panels of robust SS316L Square wire mesh with a large wire diameter (e.g., 5mm) and a relatively open mesh count (e.g., 4 mesh) for coarse debris removal. The panels were electropolished to enhance corrosion resistance and reduce biofouling adhesion.

- Outcome: The new screens drastically improved debris interception, protecting downstream equipment and reducing maintenance associated with blockages. The SS316L mesh exhibited superior corrosion resistance in the brackish water environment, extending expected service life by over 15 years, while the electropolished surface simplified cleaning procedures, contributing to overall operational efficiency.

Quality Assurance, Certifications & Partnership

Our commitment to quality is embedded throughout our operations, ensuring that every batch of Square wire mesh meets the highest industry standards and client expectations. We adhere to international quality management systems and boast a portfolio of certifications:

- ISO 9001:2015 Certified: Our manufacturing processes and quality management system are certified to ISO 9001, guaranteeing consistency, traceability, and continuous improvement.

- Material Test Certificates (MTCs): All raw materials are supplied with MTCs, ensuring full traceability to mill and compliance with chemical and mechanical property specifications (e.g., ASTM, EN, DIN, JIS standards).

- Adherence to Industry Standards: Our products conform to relevant standards for industrial wire cloth, including ISO 9044 for aperture sizes and wire diameters, and ASTM E2016 for standard test sieves and their specifications.

- In-House QA/QC: A dedicated quality assurance department conducts comprehensive checks at every stage, from incoming raw materials to final product inspection, utilizing advanced metrology and testing equipment.

- Over 20 Years of Service: With decades of specialized experience in wire mesh manufacturing, we have established ourselves as an authoritative and trusted partner for global industries.

Our long-standing partnerships with leading engineering firms and industrial corporations across petrochemical, mining, water treatment, and food processing sectors underscore our reputation for reliability and expertise.

Lead Time & Fulfillment Details

We understand the critical importance of timely delivery in industrial operations. Our lead times for Square wire mesh products are structured as follows:

- Standard Stock Items: Typically 3-7 business days for shipment, depending on volume and destination.

- Custom Woven Mesh (New Specifications): 3-5 weeks, inclusive of material sourcing, weaving, and initial quality checks.

- Custom Fabricated Components: 4-8 weeks, depending on complexity of design, secondary processing (e.g., welding, framing), and material availability.

- Expedited Orders: Available upon request for urgent requirements, subject to material availability and production scheduling. Please contact our sales team for feasibility and pricing.

We maintain strategic inventory levels of popular mesh counts and material grades to facilitate rapid turnaround for common requirements. All shipments are meticulously packaged to prevent damage during transit and are delivered globally through established logistics partners, ensuring reliable and secure delivery.

Warranty Commitments

We stand behind the quality and performance of our square wire mesh products. Our warranty commitments are designed to provide peace of mind and assure clients of our product reliability:

- Material & Workmanship Guarantee: All our Square wire mesh products are warranted against defects in material and workmanship for a period of 12 months from the date of shipment, under normal use and service conditions.

- Performance Assurance: Where specific application parameters and expected performance characteristics are mutually agreed upon prior to purchase, we guarantee that the mesh will meet those specified performance criteria.

- Replacement or Repair: In the event of a confirmed warranty claim, we will, at our discretion, repair or replace the defective product, or issue a credit for the purchase price.

This warranty does not cover damage resulting from improper installation, misuse, accident, modification, or normal wear and tear. Full warranty terms and conditions are available upon request.

Customer Support & After-Sales Service

Our dedication to client satisfaction extends far beyond the point of sale. We provide comprehensive customer support and after-sales service to ensure optimal performance and longevity of our square wire mesh products:

- Technical Consultation: Our team of experienced engineers is available to provide expert advice on material selection, mesh specification, and application design, helping you choose the most suitable solution for your needs.

- Installation Guidance: We can offer recommendations and best practices for the proper handling, installation, and maintenance of our mesh products to maximize their service life.

- Responsive Inquiry Handling: We commit to responding to all technical and commercial inquiries within 24-48 hours, ensuring prompt communication and efficient problem-solving.

- Feedback and Improvement: We actively solicit customer feedback to continuously improve our products and services, fostering long-term collaborative relationships.

For inquiries or support, please contact us via our website or direct line. Our goal is to be a reliable partner in your industrial success.

Frequently Asked Questions (FAQ)

Q1: What are the primary differences between Stainless Steel 304 and 316 for square wire mesh?

A1: Stainless Steel 316 contains molybdenum, which provides superior corrosion resistance compared to SS304, especially in chloride-rich or acidic environments (e.g., marine applications, chemical processing). SS304 is more cost-effective for general-purpose applications with less aggressive conditions.

Q2: How do I determine the correct mesh count and wire diameter for my application?

A2: This depends on the particle size you need to separate, desired flow rate, and the mechanical strength required. Finer particles require a higher mesh count and smaller wire diameter, which reduces open area. Coarser screening allows for lower mesh counts and thicker wires for greater durability. Our technical team can assist you in selecting the optimal specifications for your specific process parameters for your Square wire mesh.

Q3: Can square wire mesh be welded or formed into complex shapes?

A3: Yes, square wire mesh can be readily welded (e.g., spot welding, TIG welding) and formed, particularly when made from ductile materials like stainless steel. We offer extensive fabrication services, including cutting, bending, rolling, and welding to create custom filters, baskets, and other components tailored to your exact design requirements.

Q4: What is the typical lead time for custom square wire mesh orders?

A4: Lead times for custom orders typically range from 4 to 8 weeks, depending on material availability, the complexity of the weaving pattern, and any additional fabrication requirements. We provide a detailed lead time estimate upon quotation, and expedited options may be available for urgent projects.

Conclusion

Square wire mesh represents a vital component in modern industrial infrastructure, offering unparalleled precision, durability, and versatility for critical applications across numerous sectors. Its consistent aperture size and robust construction ensure reliable performance in filtration, separation, and reinforcement roles, contributing significantly to operational efficiency, product quality, and safety.

By leveraging advanced manufacturing processes, a broad spectrum of high-performance materials, and comprehensive customization capabilities, we provide square wire mesh solutions that meet the exacting demands of B2B clients. Our commitment to stringent quality control, backed by industry certifications and decades of expertise, positions us as a trusted partner for engineered mesh products that deliver long-term value and superior performance.

References

- Grand View Research. (2023). Industrial Filtration Market Size, Share & Trends Analysis Report. Retrieved from [Insert relevant link or indicate "available on request" if a specific live link cannot be provided.]

- ASTM International. (2023). ASTM E2016-15: Standard Specification for Industrial Woven Wire Cloth. Retrieved from www.astm.org

- International Organization for Standardization. (2000). ISO 9044:2000: Industrial wire screens — Guide to the choice of aperture size and wire diameter combinations. Retrieved from www.iso.org

- ASM International. (2001). ASM Handbook, Vol 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International.