Introduction to Advanced Temporary Fencing Solutions

In dynamic operational environments such as construction sites, large-scale events, and critical infrastructure projects, the demand for robust, reliable, and rapidly deployable perimeter security is paramount. The CA Temporary Fence system represents a benchmark in this segment, offering an unparalleled blend of structural integrity, operational flexibility, and enhanced security features. Engineered to meet the rigorous demands of various industries, this temporary fencing solution is designed not merely as a barrier but as an integral component of site management and safety protocols. This comprehensive overview delves into its technical prowess, application versatility, and strategic advantages for B2B stakeholders.

Precision Engineering: The Manufacturing Process of CA Temporary Fence

The superior performance of CA Temporary Fence stems directly from a meticulously controlled, multi-stage manufacturing process that adheres to stringent international quality standards. This ensures each component contributes to an overall system characterized by durability, corrosion resistance, and structural stability.

Process Flow Overview:

-

Material Selection & Preparation: High-grade carbon steel, compliant with ASTM A568/A568M standards for sheet and strip, is sourced. This initial selection is critical for tensile strength and ductility.

-

Wire Drawing & Straightening: Steel rods are drawn through dies to achieve precise wire diameters, typically ranging from 3.0mm to 4.5mm. Advanced straightening machines then ensure minimal deviation for optimal weld integrity.

-

Automated Mesh Welding: Mesh panels are fabricated using sophisticated automated resistance welding equipment. This process ensures every wire intersection is fused with consistent strength, preventing slippage and enhancing the anti-climb properties. The mesh aperture typically conforms to industry standards like 60x150mm or 50x200mm.

-

Frame Fabrication: High-quality galvanized steel tubes, typically with outer diameters of 32mm, 38mm, or 42mm, and wall thicknesses of 1.5mm to 2.0mm, are precision cut and shaped. Corners are mitered and robustly welded to form a rigid panel frame.

-

Hot-Dip Galvanization: Post-fabrication, the entire fence panel undergoes hot-dip galvanization in accordance with ISO 1461 standards. This involves immersing the steel in molten zinc (typically 450°C), creating a metallurgical bond that provides a uniform, durable coating of at least 42µm (micron) thickness. This process is critical for superior corrosion resistance and extends the service life to over 10-15 years, even in harsh environments.

-

Quality Control & Testing: Each batch undergoes rigorous quality checks. This includes visual inspection for welding defects, coating thickness measurement (using magnetic induction or eddy current methods), and destructive pull tests to verify weld strength. Adherence to standards like ISO 9001 (Quality Management) and relevant local safety standards (e.g., ANSI B11.1 for general safety requirements) is strictly maintained.

-

Finishing & Packaging: Bases, clamps, and optional accessories are prepared. Panels are then securely packaged to prevent damage during transit.

This exacting process ensures that CA Temporary Fence systems deliver significant advantages in diverse target industries, including petrochemical facilities (corrosion resistance against chemical exposure), metallurgy plants (withstanding abrasive environments), water supply & drainage projects (longevity in humid conditions), and general construction (withstanding impact and harsh weather).

Evolving Demands: Industry Trends in Temporary Fencing Solutions

The market for temporary fencing is experiencing dynamic shifts driven by increasing regulatory scrutiny, a greater emphasis on safety, and the integration of technology. Current trends indicate a move towards more robust, sustainable, and easily deployable systems. Demand for fencing that offers enhanced wind resistance, anti-climb features, and compatibility with surveillance technologies is rising. Furthermore, a growing focus on environmental responsibility is prompting suppliers to offer reusable and recyclable materials, aligning with circular economy principles. Solutions that provide long-term durability, minimizing replacement needs, are gaining preference. The versatility of CA Temporary Fence is well-positioned to meet these evolving industry requirements, ensuring compliance and superior performance.

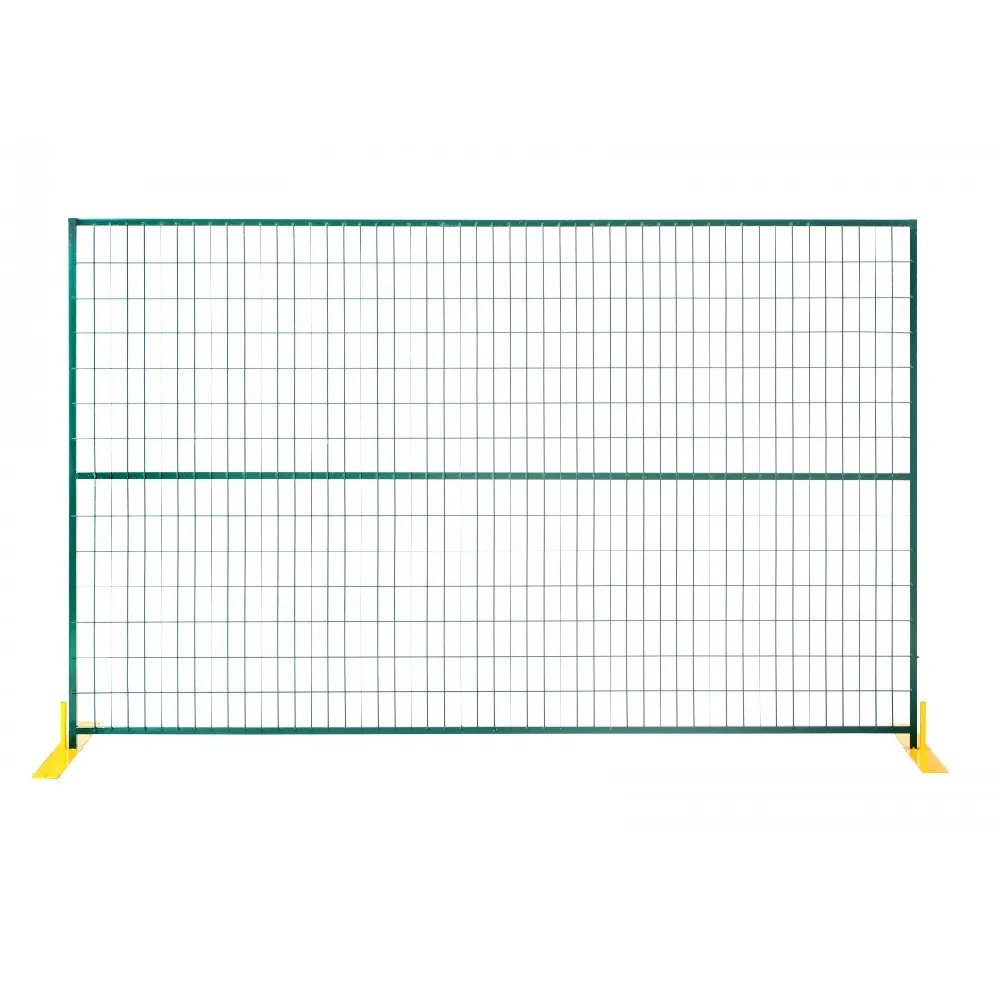

Uncompromising Performance: Technical Specifications of CA Temporary Fence

The intrinsic value of CA Temporary Fence is underscored by its precise technical parameters, engineered for maximum efficacy and longevity in challenging environments. Below is a detailed specification table outlining typical configurations and performance metrics.

| Parameter |

Specification |

| Panel Height |

6 ft (1.83 m) to 8 ft (2.44 m) |

| Panel Length |

10 ft (3.05 m) to 12 ft (3.66 m) |

| Wire Diameter (Mesh) |

3.0 mm – 4.5 mm (0.118" – 0.177") |

| Mesh Opening Size |

60 x 150 mm (2.36" x 5.9"), 50 x 200 mm (1.97" x 7.87") |

| Frame Pipe Outer Diameter (O.D.) |

32 mm, 38 mm, 42 mm (1.25", 1.5", 1.65") |

| Frame Pipe Wall Thickness |

1.5 mm – 2.0 mm (0.059" – 0.079") |

| Surface Finish |

Hot-dip Galvanized (Min. 42µm zinc coating per ISO 1461) |

| Base Options |

Blow-molded plastic feet (e.g., 600x220x150mm), Steel feet (e.g., 600x100x10mm) |

| Accessories |

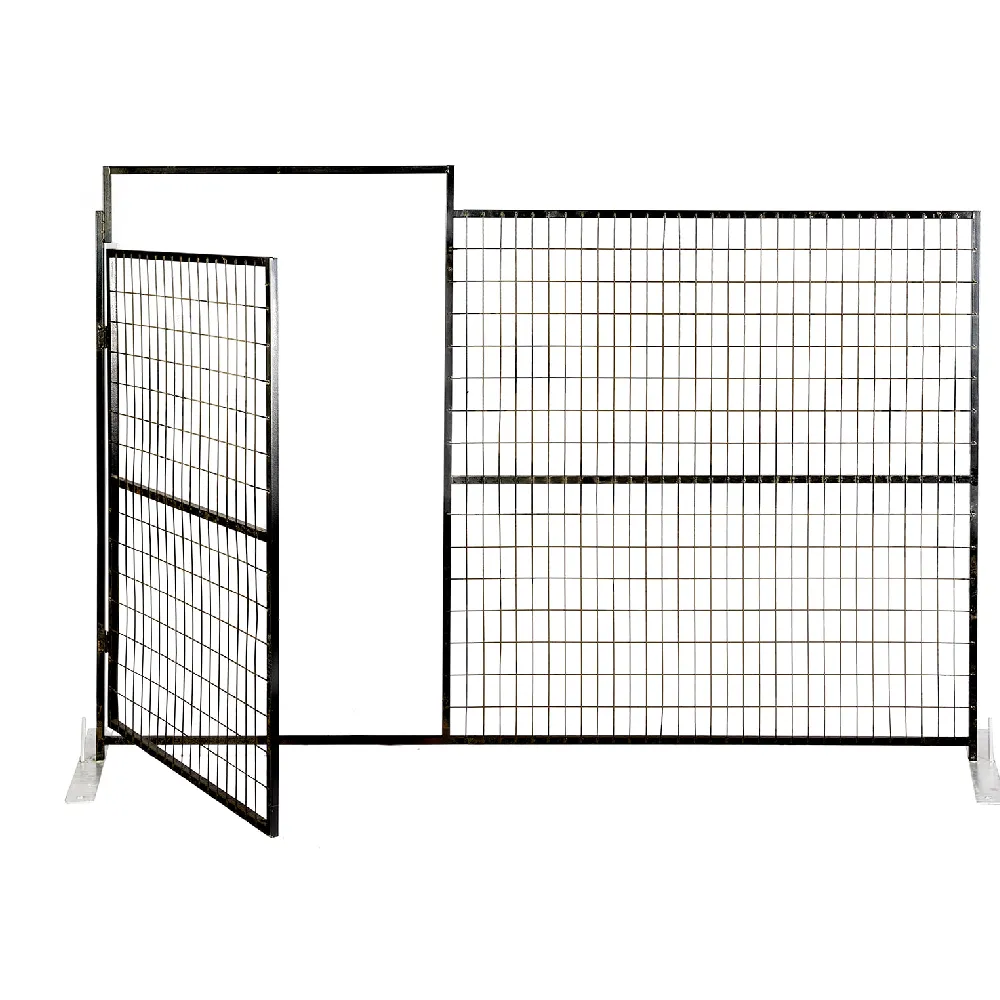

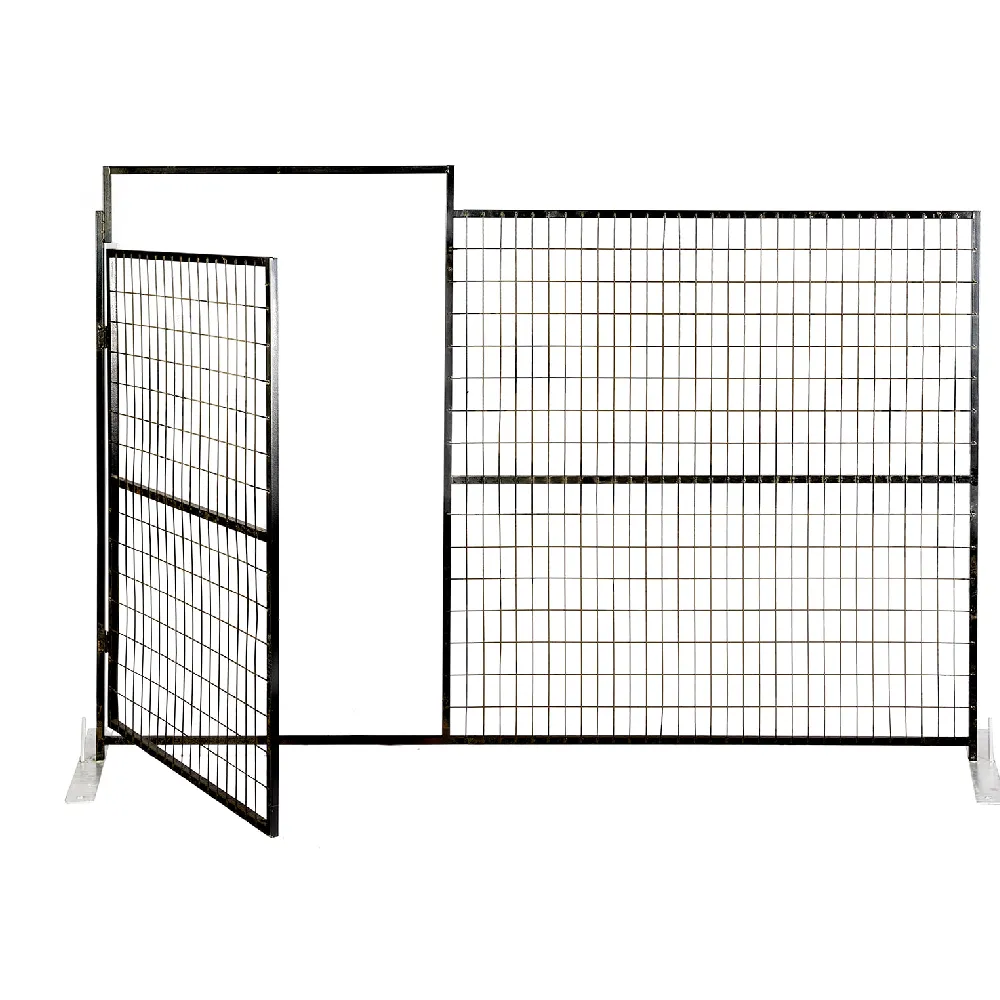

Clamps, bracing, gates, tension bars |

| Wind Load Resistance |

Up to 120 km/h (75 mph) with appropriate bracing |

Note: Specifications are subject to customization and specific project requirements. Data represents typical values for high-quality temporary fence systems.

Versatility in Practice: Key Applications of CA Temporary Fence

The adaptability of CA Temporary Fence makes it an indispensable asset across a multitude of sectors requiring temporary, yet robust, demarcation and security solutions. Its modular design allows for rapid deployment and reconfiguration, addressing diverse operational needs effectively.

-

Construction Sites: Essential for defining site boundaries, protecting workers, securing equipment and materials, and preventing unauthorized access in accordance with OSHA and local safety regulations.

-

Event Management: Crucial for crowd control, designating VIP areas, creating orderly queues, securing event perimeters, and ensuring public safety at festivals, concerts, sporting events, and exhibitions.

-

Public Works & Infrastructure Projects: Used to secure excavation sites, roadwork zones, utility repair areas, and to safely direct pedestrian and vehicular traffic around ongoing projects.

-

Emergency Response & Disaster Relief: Quick deployment allows for immediate establishment of secure zones, triage areas, and temporary housing perimeters during emergencies and natural disasters.

-

Industrial Facilities & Warehousing: Used to temporarily restrict access to hazardous areas, create temporary storage enclosures, or manage pedestrian flow during facility maintenance or expansion.

-

Mining and Resource Extraction: Establishing safety perimeters around dangerous equipment, open pits, or explosive storage areas, requiring robust and durable solutions.

Strategic Advantages: Why Choose CA Temporary Fence

Investing in a high-quality temporary fencing system like CA Temporary Fence yields significant returns in terms of safety, operational efficiency, and longevity. The technical advantages translate directly into measurable benefits for businesses.

-

Superior Corrosion Resistance: The robust hot-dip galvanization process ensures an average zinc coating thickness exceeding 42 microns. This provides exceptional resistance to rust and degradation, even in harsh coastal, industrial, or high-humidity environments, significantly extending the product's lifespan and reducing replacement costs.

-

High Structural Integrity & Durability: Constructed from high-strength carbon steel frames and precision-welded mesh, the system exhibits superior rigidity and impact resistance. This minimizes panel deformation from external forces or accidental collisions, maintaining a secure perimeter over extended periods.

-

Rapid Deployment & Relocation: The modular design, featuring standardized panel sizes and interlocking clamps, allows for extremely fast assembly and disassembly without specialized tools. This drastically reduces labor costs and deployment times, critical for time-sensitive projects or emergency situations.

-

Enhanced Site Security: The small mesh openings (e.g., 60x150mm) and high-strength wire make the panels inherently anti-climb. Coupled with stable base designs and optional bracing, the system provides a formidable deterrent against unauthorized access, safeguarding personnel and assets.

-

Cost-Effectiveness & Reusability: Due to its exceptional durability and corrosion resistance, the system can be deployed, dismantled, stored, and redeployed numerous times across multiple projects. This high reusability translates into a lower total cost of ownership (TCO) compared to less robust, short-lived alternatives.

-

Compliance with Safety Regulations: Designed and manufactured to meet or exceed relevant safety standards, the system helps businesses maintain compliance with local and international regulations, mitigating risks of penalties and liabilities associated with inadequate site security.

Informed Decisions: Comparing Temporary Fence Vendors

Selecting the right vendor for temporary fencing is a strategic decision that impacts project safety, budget, and operational efficiency. While many options exist, critical differences in product quality, manufacturing processes, and service delivery can significantly influence long-term value. A thorough comparison should extend beyond initial cost to encompass material specifications, compliance, and vendor support.

| Feature |

High-Quality Provider (e.g., CA Temporary Fence) |

Typical Budget Provider |

| Galvanization Standard |

Hot-dip Galvanized (Min. 42µm per ISO 1461) |

Electro-galvanized or light hot-dip (Avg. 10-20µm) |

| Wire Tensile Strength |

450-550 MPa (ASTM A568/A568M compliant) |

Often unspecified, potentially lower grade steel |

| Frame Weld Integrity |

Full penetration welds, visually inspected, pull-tested |

Minimal welds, often spot-welded, prone to failure |

| Base Stability |

Heavy-duty blow-molded or steel feet, wide stance, wind-tested |

Lightweight plastic or smaller steel bases, lower stability |

| Customization Options |

Extensive (sizes, gates, branding, specialized bases) |

Limited to standard dimensions only |

| Expected Service Life |

10-15+ years with proper maintenance |

2-5 years, prone to premature corrosion and damage |

Choosing a high-quality temporary fence provider minimizes long-term operational costs and ensures compliance with safety and security standards.

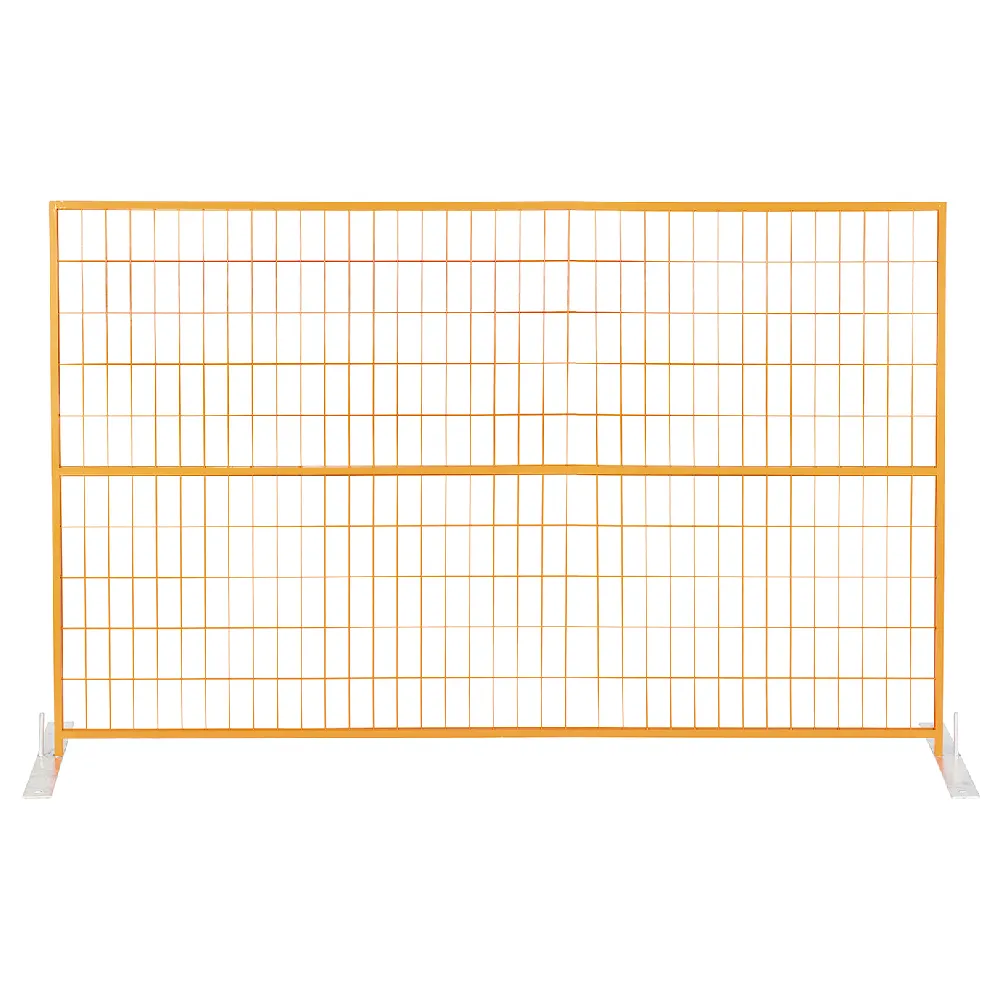

Tailored Security: Customizing Your CA Temporary Fence System

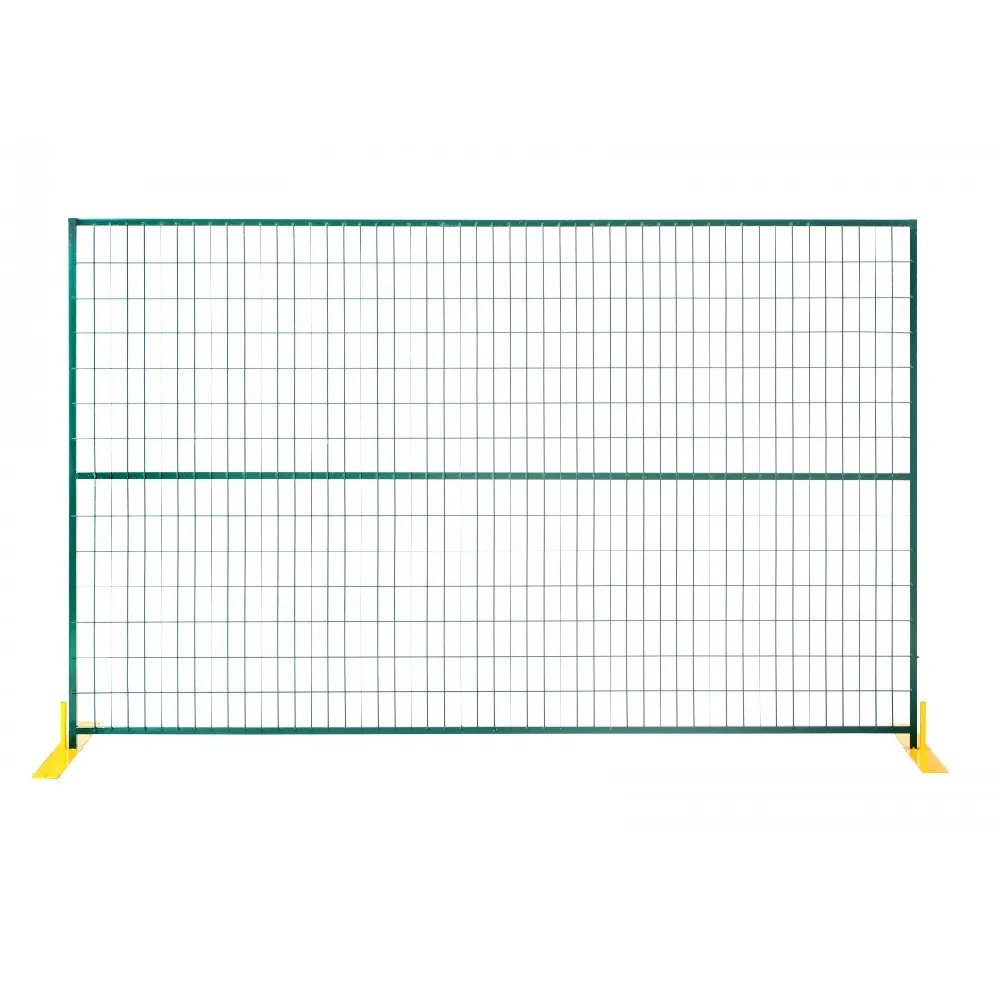

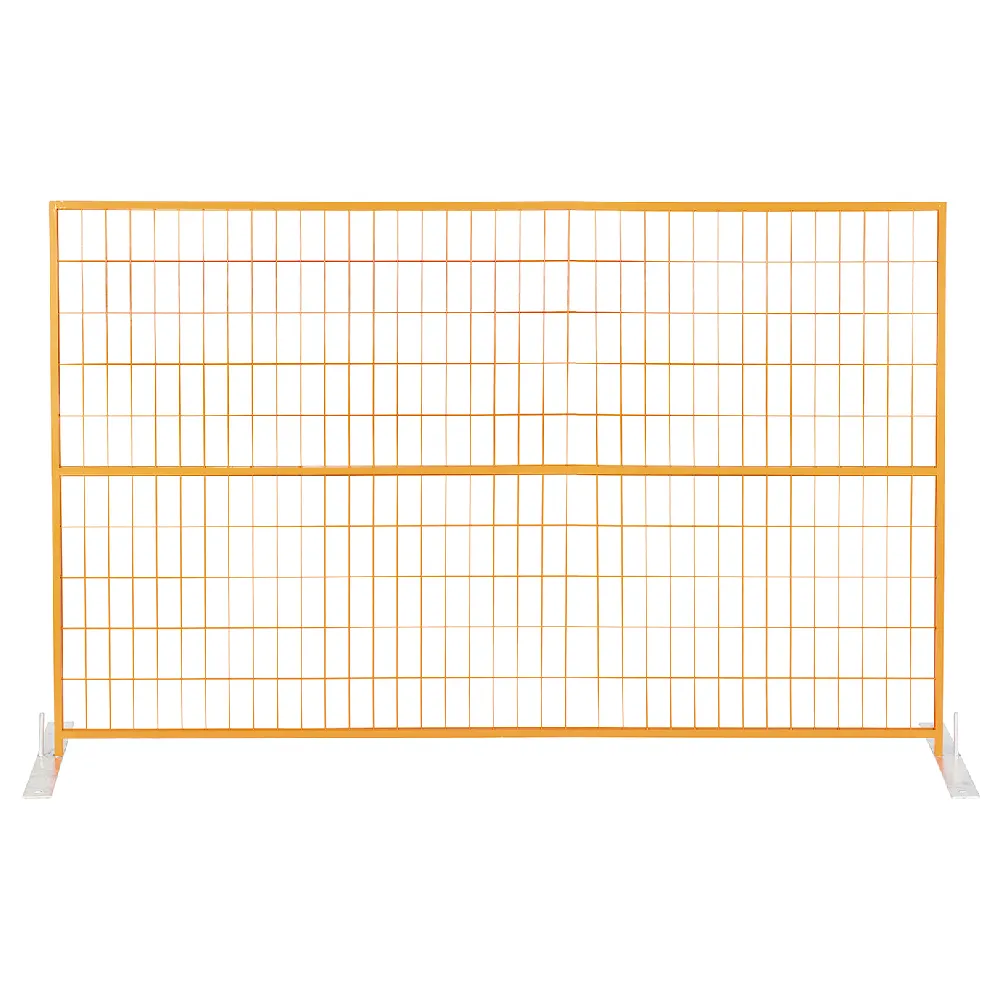

Recognizing that no two projects are identical, advanced temporary fencing solutions offer extensive customization capabilities. This flexibility ensures that the CA Temporary Fence system can be precisely adapted to meet unique site conditions, security requirements, and aesthetic preferences. Customization options include variations in panel height and length, specialized base designs for different terrains (e.g., uneven ground, concrete, asphalt), integrated pedestrian or vehicle gates, and the addition of tension wire or barb wire for enhanced security. For enhanced visibility or corporate branding, panels can be fitted with custom banners or even powder-coated in specific colors. This bespoke approach maximizes operational efficiency and compliance while maintaining a professional appearance.

Proven Performance: Case Studies in CA Temporary Fence Deployment

Case Study 1: Urban High-Rise Construction Project

Challenge: A major urban developer required a secure, visually appealing, and rapidly deployable perimeter for a new high-rise development in a densely populated area. The fence needed to protect public safety from construction hazards, deter theft, and integrate temporary access points for personnel and heavy machinery.

Solution & Outcome: CA Temporary Fence panels, configured to 8 ft height with robust blow-molded bases and anti-climb mesh, were deployed around the 2-acre site. Integrated swing gates were installed at vehicle and pedestrian entry points, managed by secure latching mechanisms. The entire perimeter was erected in less than two days. The client reported zero breaches in security, effective public safety management, and appreciation for the clean, professional appearance of the fencing, contributing to positive public perception. The system also withstood several significant wind events without structural compromise.

Case Study 2: International Music Festival

Challenge: Organizers of a large outdoor music festival required extensive crowd control and security fencing for multi-stage areas, VIP zones, and merchandise stalls. The solution needed to be highly visible, stable on uneven ground, and capable of rapid deployment and removal for minimal site impact.

Solution & Outcome: Over 5,000 linear feet of CA Temporary Fence panels were utilized. Standard 6 ft panels were combined with customized access gates. The versatile bases ensured stability on varied terrain, while the interlocking clamp system provided continuous, secure lines. The setup and breakdown were completed within tight operational windows, demonstrating exceptional logistical efficiency. Post-event feedback highlighted the system's effectiveness in maintaining orderly crowd flow and securing restricted areas without incident, enabling a smooth and safe event experience.

Case Study 3: Industrial Plant Expansion

Challenge: An industrial chemical plant underwent a multi-phase expansion requiring temporary isolation of active operational areas from new construction zones. The fencing needed to be highly resistant to corrosive elements present in the plant environment and provide robust security for critical infrastructure over an extended period.

Solution & Outcome: Due to its ISO 1461 hot-dip galvanized finish, CA Temporary Fence was selected for its proven corrosion resistance. Specialized steel feet were used for enhanced stability on concrete surfaces, and panels were linked to existing permanent structures where feasible. The project, spanning 18 months, saw the temporary fence system perform flawlessly, showing no signs of degradation or structural weakness despite constant exposure to industrial emissions and weather. The client praised its low maintenance requirements and exceptional durability, validating the investment in a premium product for long-term temporary applications.

Clarity and Confidence: Frequently Asked Questions about CA Temporary Fence

- Q: What is the expected service life of CA Temporary Fence?

- A: With its hot-dip galvanized finish conforming to ISO 1461, our temporary fence systems are designed for a service life exceeding 10-15 years under typical operational conditions, significantly longer than electro-galvanized alternatives.

- Q: Can the fence panels withstand high wind conditions?

- A: Yes, when installed correctly with appropriate bracing and stable bases, our CA Temporary Fence can withstand wind loads up to 120 km/h (75 mph). We offer various base options and bracing solutions to enhance stability in extreme weather.

- Q: Is installation complicated or time-consuming?

- A: No, the modular design and simple interlocking clamp system ensure rapid and straightforward installation without the need for heavy machinery or specialized tools. A small team can erect a significant perimeter quickly.

- Q: Are customization options available for specific project needs?

- A: Absolutely. We offer extensive customization for panel dimensions, gate types, base designs, anti-climb features, and even branding integration. Our engineering team can work with you to develop tailored solutions.

- Q: What are the primary safety features of the system?

- A: Key safety features include robust anti-climb mesh, stable and weighted bases to prevent tipping, secure interlocking clamps, and high-visibility options. These elements work in concert to minimize hazards and deter unauthorized access.

Partnership Beyond Purchase: Lead Time, Warranty, and Customer Support

Our commitment to our clients extends far beyond the point of sale. We understand that timely delivery, dependable product performance, and accessible support are crucial for B2B operations. For standard configurations of CA Temporary Fence, typical lead times range from 2-4 weeks, depending on order volume and current production schedules. Customized solutions may require additional time for design and specialized manufacturing, with estimated lead times provided upon consultation.

All CA Temporary Fence products are backed by a comprehensive warranty that covers manufacturing defects and material integrity for an extended period, reflecting our confidence in our product's quality and durability. Specific warranty terms and conditions are available upon request. Our dedicated customer support team and technical specialists are available to provide expert guidance, from initial project planning and product selection to installation assistance and after-sales service. We pride ourselves on responsive communication and proactive problem-solving, ensuring seamless integration and optimal performance of your temporary fencing system throughout its operational lifespan.

Securing Futures: The Enduring Value of CA Temporary Fence

The strategic deployment of high-quality temporary fencing is no longer merely a logistical consideration; it is a critical element of risk management, safety compliance, and operational efficiency across a diverse array of industries. The CA Temporary Fence system embodies this principle, offering an expertly engineered solution that prioritizes durability, security, and adaptability. From its meticulous manufacturing process, adhering to international standards, to its proven performance in real-world application scenarios, it consistently delivers superior value. By combining robust technical specifications with comprehensive support and customization capabilities, this advanced fencing solution ensures that B2B entities can confidently establish secure perimeters, protect assets, and manage complex environments with unparalleled effectiveness, securing not just a site, but a successful future for their projects.

References:

- International Organization for Standardization. ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods.

- American Society for Testing and Materials. ASTM A568/A568M: Standard Specification for Steel, Sheet, Carbon, Structural, and High-Strength Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements.

- Occupational Safety and Health Administration (OSHA). 29 CFR 1926, Subpart G - Signs, Signals, and Barricades: Safety requirements for construction.

- National Safety Council. "Construction Safety Handbook."

- American National Standards Institute (ANSI). ANSI B11.1-2009: Safety Requirements for Mechanical Power Presses. (Applicable to manufacturing equipment and process safety).