Introduction to Advanced Erosion Control Solutions

In contemporary civil engineering and environmental protection, the demand for robust, adaptable, and sustainable solutions for erosion control, soil stabilization, and hydraulic structures has never been more critical. Facing escalating climate impacts and the imperative for resilient infrastructure, engineers and project managers are increasingly turning to advanced materials that offer longevity and performance under challenging conditions. Among these, the PVC Coated Hexagonal Gabion stands out as a superior choice. This engineered system combines the inherent strength and flexibility of double-twisted steel wire mesh with the unparalleled corrosion resistance of a Polyvinyl Chloride (PVC) coating, delivering a product with an extended service life in aggressive environments. This article delves into the technical intricacies, application versatility, and strategic advantages of this essential engineering component, targeting B2B decision-makers seeking reliable and cost-effective infrastructure solutions.

Industry Trends in Geo-Engineering and Environmental Management

The global geo-engineering and environmental management sectors are undergoing significant transformation, driven by several key trends. There is an accelerating shift towards sustainable and eco-friendly construction materials that minimize environmental footprint while maximizing durability. Climate change mitigation and adaptation efforts necessitate robust solutions for flood control, landslide prevention, and coastal protection. Furthermore, infrastructure projects increasingly demand materials that offer long-term performance with minimal maintenance requirements, especially in remote or challenging terrains. The versatility and structural integrity of gabion systems, particularly those enhanced with advanced coatings, position them as front-runners in meeting these evolving demands. Their ability to integrate with natural landscapes and support revegetation further aligns with green infrastructure initiatives. Data from the global gabion market indicates a consistent growth, projected to reach USD 1.1 billion by 2027, driven by increased investments in infrastructure development and disaster preparedness, underscoring the critical role of products like PVC Coated Hexagonal Gabion in future-proofing our built environment.

Technical Specifications and Advanced Material Science of PVC Coated Hexagonal Gabion

The superior performance of a PVC Coated Hexagonal Gabion is rooted in its meticulously engineered design and material selection. The core structure comprises high-quality low-carbon steel wire, typically conforming to ASTM A641/A975 or EN 10223-3 standards, which is heavily galvanized with a zinc coating to provide initial corrosion protection. This galvanized wire is then woven into a double-twisted hexagonal mesh pattern. This double-twist mechanism is crucial as it prevents unraveling in the event of wire breakage, maintaining the structural integrity of the entire unit. Over this galvanized base, a durable PVC coating is extruded onto the wire. This PVC layer, typically between 0.5 mm and 0.8 mm thick, acts as a formidable barrier against chemical degradation, abrasion, and UV radiation, significantly extending the service life of the gabion in aggressive environments such as saltwater, acidic soils, or polluted water bodies. The technical parameters are carefully calibrated to ensure optimal performance across diverse applications.

Standard Product Specifications

| Parameter |

Specification Range |

Relevant Standard |

| Mesh Type |

Double Twisted Hexagonal |

ASTM A975-97 / EN 10223-3 |

| Wire Diameter (Core) |

2.0 mm - 4.0 mm |

ASTM A641 / EN 10218-2 |

| PVC Coating Thickness |

0.5 mm - 0.8 mm (min. average) |

ASTM A975 / EN 10245-2 |

| Mesh Opening (D x D) |

60x80 mm, 80x100 mm, 100x120 mm |

ASTM A975 / EN 10223-3 |

| Tensile Strength of Wire |

380-550 N/mm² |

EN 10223-3 |

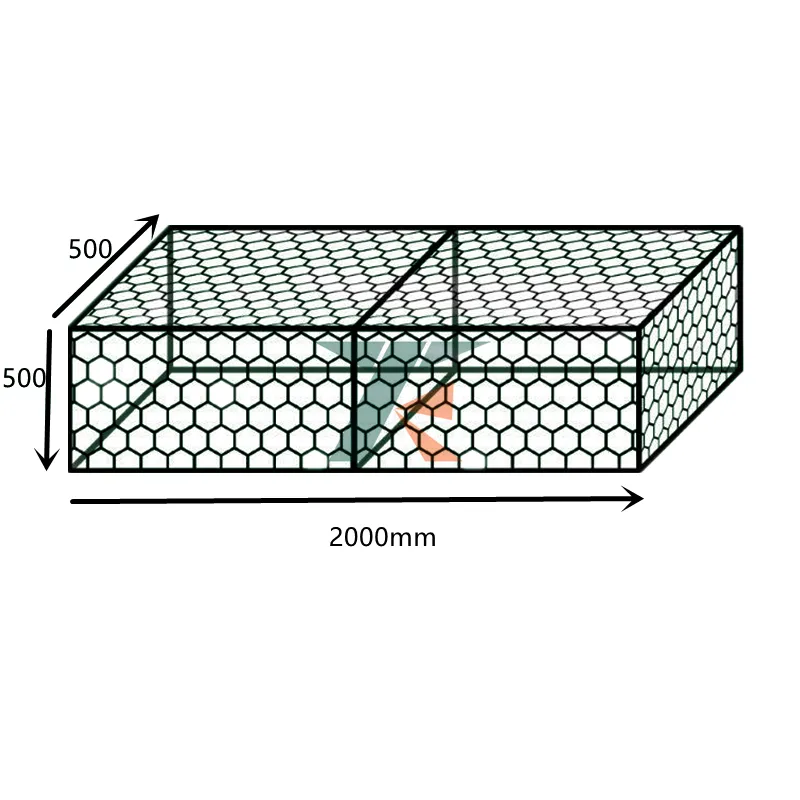

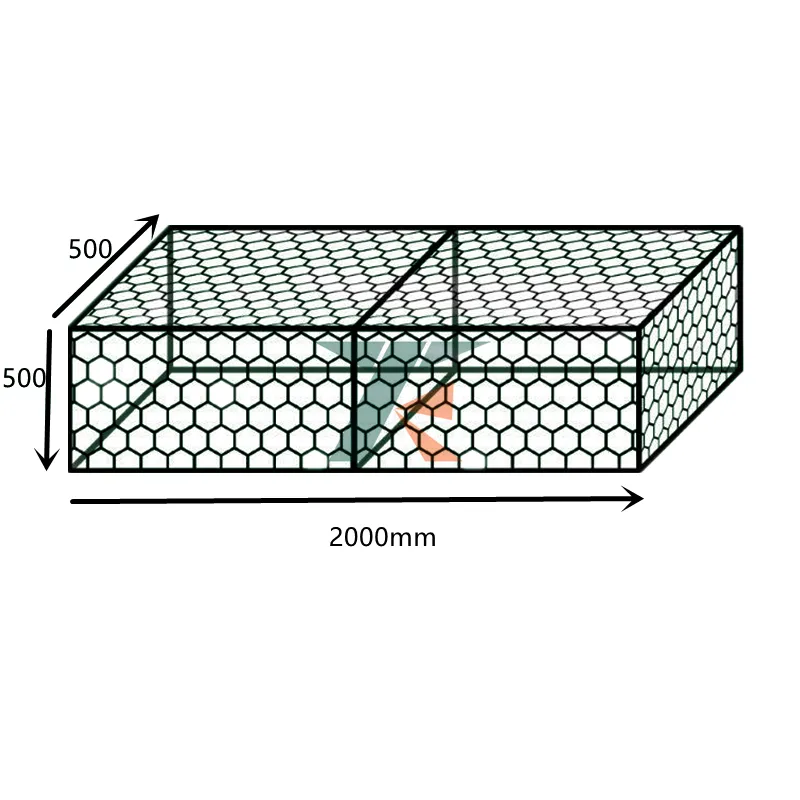

| Unit Dimensions (L x W x H) |

Various, e.g., 2x1x1m, 3x1x1m, 4x1x1m |

Customizable |

Manufacturing Process Flow of PVC Coated Hexagonal Gabion

The production of a PVC Coated Hexagonal Gabion involves a series of precision-controlled stages to ensure material integrity and consistent product quality:

-

Wire Material Sourcing & Testing: High-tensile, low-carbon steel wire rods are sourced and subjected to rigorous incoming quality control, including chemical composition analysis, tensile strength tests, and elongation assessments, adhering to ISO 6892-1.

-

Wire Drawing: The raw wire rods are drawn through a series of dies to achieve the precise final diameter required for the gabion mesh. This process enhances the wire's tensile strength and surface finish.

-

Hot-Dip Galvanization: The drawn steel wire undergoes a hot-dip galvanization process, where it is immersed in molten zinc. This creates a metallurgical bond, providing a thick, durable zinc coating that offers sacrificial and barrier protection against corrosion, complying with ASTM A641/A90 or EN 10244-2.

-

PVC Coating Application: The galvanized wire is then fed into an extrusion line where a uniform layer of PVC is applied. This process ensures complete encapsulation of the galvanized wire, providing superior resistance to chemical attack, abrasion, and UV degradation. The thickness and adhesion of the PVC layer are continuously monitored and tested according to ASTM A975 or EN 10245-2 standards.

-

Double-Twist Weaving: The PVC-coated wire is fed into specialized hexagonal weaving machines. These machines create the distinctive double-twist mesh pattern, ensuring that individual wire breaks do not propagate, thereby maintaining the structural integrity of the mesh panel. Mesh opening size and wire spacing are precisely controlled.

-

Cutting and Edging: Woven mesh rolls are cut to the specified dimensions for gabion boxes or mattresses. Edges are reinforced with heavier gauge wire (selvage wire), which is incorporated during the weaving process or attached subsequently, to enhance panel strength and facilitate assembly.

-

Panel Assembly and Folding: The cut and edged mesh panels (base, sides, ends, internal diaphragms) are then assembled, often pre-laced or spiraled, and folded flat for efficient transportation.

-

Quality Control & Packaging: Each unit undergoes final quality inspections for dimensions, mesh integrity, coating adhesion, and overall finish. Gabions are then bundled and packaged, typically in compact forms, to minimize shipping volume and protect them during transit.

Application Scenarios and Target Industries

The inherent flexibility, permeability, and structural integrity of PVC Coated Hexagonal Gabion systems make them indispensable across a wide spectrum of engineering and environmental applications. Their adaptability allows them to be used in dynamic environments where rigid structures may fail, and their robust construction ensures longevity even in aggressive conditions. The target industries benefiting from this technology are diverse and critical to global infrastructure.

-

River and Channel Works: For river bank protection, channel lining, and scour protection around bridge abutments, gabions provide flexible, permeable structures that adapt to hydraulic forces without cracking. They dissipate energy, prevent erosion, and allow for natural vegetation growth, enhancing ecological value.

-

Retaining Walls: Gabion retaining walls are widely used for slope stabilization, creating level platforms, and supporting embankments in highway, railway, and urban development projects. Their mass gravity structure, combined with flexibility, offers excellent resistance to differential settlement.

-

Slope Stabilization and Erosion Control: In mountainous regions or areas prone to landslides, gabions are deployed as facing for reinforced earth slopes or as check dams to control sediment movement and stabilize steep gradients. Their permeability prevents the buildup of hydrostatic pressure behind the structure.

-

Coastal Protection: In marine environments, where structures are exposed to corrosive saltwater and wave action, PVC-coated gabions are ideal for seawalls, groynes, and revetments. The PVC coating provides superior resistance to saline degradation, extending the structure's service life beyond that of traditional galvanized gabions.

-

Mining and Industrial Sites: Gabions are used for perimeter protection, sediment ponds, and land reclamation at industrial and mining facilities, where chemical exposure and heavy loads are common. The enhanced corrosion resistance is particularly beneficial here.

-

Landscaping and Architectural Applications: Beyond their functional benefits, gabions are increasingly integrated into modern landscape design for decorative walls, garden features, and sound barriers, offering an aesthetic appeal that blends with natural environments.

In petrochemical and water supply & drainage sectors, the exceptional corrosion resistance provided by the PVC coating is paramount. For instance, in wastewater treatment plants or areas with soil contamination, the gabions remain structurally sound, ensuring long-term integrity of critical infrastructure and minimizing costly maintenance cycles. The extended service life in such scenarios directly translates to reduced lifecycle costs and enhanced operational safety.

Key Technical Advantages of PVC Coated Hexagonal Gabion Systems

The integration of a PVC coating with the robust hexagonal gabion mesh provides a suite of technical advantages that are critical for demanding engineering applications:

-

Superior Corrosion Resistance: The primary advantage is the enhanced protection against aggressive environmental elements. The PVC coating creates an impervious barrier against saltwater, acidic or alkaline soils, industrial pollutants, and various chemicals. This significantly extends the service life, often exceeding 75 years in environments where galvanized-only gabions would degrade much faster. This makes them ideal for marine, coastal, and heavily contaminated industrial sites.

-

Exceptional Durability and Longevity: Combining the high tensile strength of the steel wire with the protective PVC layer results in a structure that is remarkably resilient to physical abrasion, impact, and environmental wear. The double-twist mesh prevents catastrophic failure by localized damage.

-

Flexibility and Adaptability: Unlike rigid concrete structures, gabion systems possess inherent flexibility. They can deform without fracturing when subjected to differential ground settlement, seismic activity, or hydraulic pressures, making them highly suitable for unstable ground conditions or dynamic water environments.

-

Excellent Permeability: The open nature of the gabion structure, when filled with stone, allows water to flow through freely. This prevents the buildup of hydrostatic pressure behind the structure, a common cause of failure in impermeable retaining walls. It also facilitates natural drainage and reduces uplift forces.

-

Environmental Compatibility and Eco-Engineering: Gabions can be filled with locally available stones or recycled aggregates, reducing transportation costs and environmental impact. Their permeable design encourages natural vegetation growth within and around the structure over time, integrating it with the landscape and enhancing biodiversity, thus supporting energy saving through natural means.

-

Cost-Effectiveness and Ease of Installation: Despite the advanced coating, the overall lifecycle cost of PVC-coated gabions is highly competitive due to their long service life and minimal maintenance requirements. They are relatively simple to install, often requiring less specialized equipment and labor than traditional concrete structures, leading to faster project completion.

-

UV and Chemical Stability: The PVC coating is formulated to resist degradation from ultraviolet radiation and a wide range of chemicals, ensuring its protective properties are maintained over decades of exposure to sunlight and harsh substances.

Vendor Comparison and Selection Criteria for Gabion Suppliers

Selecting the right vendor for PVC Coated Hexagonal Gabion products is critical to project success, ensuring material quality, timely delivery, and long-term performance. B2B decision-makers must evaluate suppliers based on a comprehensive set of criteria beyond just initial cost. A strategic vendor partnership contributes significantly to risk mitigation and value optimization throughout the project lifecycle.

Key Evaluation Metrics for Gabion Suppliers

| Criterion |

Description & Importance |

| Material Quality & Standards Adherence |

Verification of wire composition, galvanization thickness, PVC coating quality (adhesion, thickness, UV resistance), and compliance with international standards (e.g., ASTM A975, EN 10223-3, ISO 9001). This directly impacts product lifespan and performance. |

| Manufacturing Capabilities & Capacity |

Assessing the vendor's ability to produce required volumes, adherence to consistent quality, and technological advancement in their production lines. Critical for large-scale projects and tight deadlines. |

| Technical Support & Engineering Expertise |

Availability of experienced engineers for design assistance, installation guidance, and problem-solving. A vendor offering comprehensive technical support adds significant value beyond mere product supply. |

| Customization Options |

Flexibility to provide gabions of varying dimensions, mesh sizes, wire gauges, and coating specifications to meet unique project requirements. |

| Logistics and Supply Chain Reliability |

Efficiency in order fulfillment, lead times, shipping, and global distribution network. Delays can be costly for large infrastructure projects. |

| Reputation & Project References |

Track record of successful projects, client testimonials, and industry recognition. Verifiable past performance is a strong indicator of future reliability. |

| Warranty & After-Sales Support |

Clear warranty terms for material and coating lifespan, along with accessible after-sales service for any issues or future project phases. |

Customized Solutions for Complex Engineering Projects

While standard PVC Coated Hexagonal Gabion units meet the requirements of many projects, complex engineering challenges often demand tailored solutions. Reputable manufacturers offer extensive customization capabilities to address specific site conditions, hydraulic forces, aesthetic considerations, or structural demands. This level of flexibility ensures optimal performance and cost-efficiency, eliminating the need for costly field modifications or compromises in design.

-

Varying Dimensions: Gabions can be manufactured in a wide range of lengths, widths, and heights to fit specific site geometries, from small landscaping features to massive retaining walls or river training structures. This includes custom box sizes, mattress units, or sack gabions.

-

Mesh Opening and Wire Gauge: Depending on the filling material (stone size) and the anticipated hydraulic or structural loads, the mesh opening size (e.g., 60x80mm, 80x100mm, 100x120mm) and wire diameter (e.g., 2.2mm to 4.0mm core wire) can be specified. This optimizes the balance between structural strength and permeability.

-

PVC Coating Thickness and Formulation: For extremely aggressive environments (e.g., highly acidic industrial run-off, severe coastal erosion), the PVC coating thickness can be increased, or specialized PVC formulations with enhanced chemical resistance can be applied.

-

Integrated Geotextile Elements: For applications requiring additional filtration or separation, gabions can be supplied with integrated geotextile filters or separators, simplifying installation and ensuring subgrade stability.

-

Pre-filled or Modular Systems: In certain scenarios, particularly for rapid deployment or limited access sites, gabions can be provided as pre-filled modules or with specialized lifting arrangements for expedited installation.

Effective customization involves close collaboration between the client's engineering team and the supplier's technical experts. This partnership ensures that design intent translates precisely into manufactured product specifications, leading to robust, long-lasting, and fully compliant solutions.

Real-World Application Case Studies

The effectiveness of PVC Coated Hexagonal Gabion systems is best demonstrated through their successful deployment in real-world infrastructure projects. These case studies highlight their reliability, adaptability, and economic benefits under diverse and challenging conditions.

Case Study 1: Coastal Protection in a High-Salinity Environment

A major coastal erosion mitigation project along a highly saline coastline in Southeast Asia required a robust and durable solution to protect critical infrastructure from wave action and tidal scour. Traditional galvanized gabions had shown limited longevity in similar high-salinity zones, necessitating frequent maintenance. The engineering firm specified PVC Coated Hexagonal Gabion units (4x1x1m, 80x100mm mesh, 3.0mm core wire with 0.6mm PVC coating) for the construction of a 2 km revetment. The project was completed in 18 months, utilizing local stone fill. Post-installation monitoring over five years has shown no signs of corrosion on the PVC-coated wire, even after continuous exposure to aggressive saltwater. The flexibility of the gabion structure also allowed it to naturally settle and adapt to minor ground movements, maintaining its structural integrity and protective function, leading to significant cost savings on maintenance compared to alternatives.

Case Study 2: Highway Embankment Stabilization in an Acidic Soil Region

A new highway construction project in a region characterized by naturally acidic soils and heavy rainfall required the stabilization of several steep embankments. The challenging soil chemistry presented a significant risk of rapid corrosion for conventional steel structures. Gabion retaining walls, constructed using PVC Coated Hexagonal Gabion baskets (2x1x0.5m, 60x80mm mesh, 2.7mm core wire with 0.5mm PVC coating), were selected for their proven corrosion resistance and ability to handle differential settlement. Over a 10-year observation period, the gabion walls have exhibited exceptional stability and structural integrity. The PVC coating effectively shielded the underlying galvanized wire from the aggressive soil environment, while the permeable nature of the gabions prevented the build-up of hydrostatic pressure, which could otherwise destabilize the slopes. This solution provided a long-term, low-maintenance alternative to reinforced concrete walls, proving both economically and environmentally beneficial.

Ensuring Trust: Certifications, Warranties, and Support

For B2B buyers, trustworthiness is paramount. A reputable supplier of PVC Coated Hexagonal Gabion products provides comprehensive assurances regarding quality, compliance, and ongoing support, adhering to the highest industry standards.

Company and Product Certifications

Our manufacturing processes and products are rigorously tested and certified by independent third-party bodies to ensure compliance with international quality and environmental management standards. Key certifications typically include:

- ISO 9001:2015 (Quality Management System): Assures consistent product quality and customer satisfaction through effective process control.

- ISO 14001:2015 (Environmental Management System): Demonstrates our commitment to sustainable production practices and minimizing environmental impact.

- ASTM A975-97 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses): Verifies that the gabion mesh structure and materials meet specified performance criteria.

- EN 10223-3:2013 (Steel wire and wire products for fencing and netting – Hexagonal steel wire netting for civil engineering purposes): Confirms adherence to European standards for gabion wire mesh.

- EN 10244-2:2009 (Steel wire and wire products – Non-ferrous metallic coatings on steel wire – Zinc or zinc alloy coatings): Specifies requirements for the galvanized coating.

- EN 10245-2:2011 (Steel wire and wire products – Organic coatings on steel wire – PVC coatings): Outlines specifications for the PVC coating, including thickness and adhesion.

Lead Time and Fulfillment Details

We maintain robust production capabilities and a streamlined logistics network to ensure timely delivery for projects of any scale. Standard lead times for PVC Coated Hexagonal Gabion typically range from 2-4 weeks, depending on order volume and specific customization requirements. Expedited production and shipping options are available for urgent projects. Our global supply chain management ensures efficient transport from manufacturing facilities to project sites worldwide, providing transparent tracking and dedicated logistics support.

Warranty Commitments

We stand by the quality and durability of our products. Our PVC Coated Hexagonal Gabion units are backed by comprehensive warranties. Typically, we offer a 10-year warranty on the galvanized wire against manufacturing defects and a 25-year warranty on the PVC coating against degradation under normal environmental conditions. Specific warranty terms may vary based on project type and environmental exposure, and are always clearly outlined in project contracts.

Customer Support and Technical Assistance

Our commitment extends beyond product delivery. We provide extensive customer support and technical assistance throughout all project phases. This includes pre-sales consultation, engineering design support, installation guidance, and post-sales service. Our team of experienced geo-engineers and technical specialists is available to assist with site-specific queries, product selection, and any challenges that may arise during installation or operation. We believe in fostering long-term partnerships based on reliable products and unparalleled service.

Frequently Asked Questions (FAQ)

Q1: What is the typical service life of a PVC Coated Hexagonal Gabion compared to a galvanized one?

A1: While a standard galvanized gabion can last 20-30 years in mild environments, a PVC-coated variant significantly extends this. In aggressive conditions (e.g., marine, industrial, highly acidic soils), PVC-coated gabions are designed to last 50-75 years or more, thanks to the added chemical and abrasion resistance of the PVC layer.

Q2: Can gabions be used in areas with seismic activity?

A2: Yes, a significant advantage of gabion structures, including PVC Coated Hexagonal Gabion units, is their inherent flexibility. Unlike rigid concrete structures, gabions can deform and adjust to ground movements during seismic events without losing their structural integrity, making them highly suitable for earthquake-prone regions.

Q3: What are the environmental benefits of using PVC-coated gabions?

A3: PVC-coated gabions offer several environmental benefits: they are permeable, allowing water flow and supporting natural drainage; they can be filled with local materials, reducing transport emissions; they encourage vegetation growth, aiding ecological integration and habitat creation; and their long lifespan minimizes the need for frequent replacement, reducing resource consumption.

Q4: Is specialized equipment required for gabion installation?

A4: While large-scale projects benefit from mechanical assistance for stone filling, the basic assembly and lacing of gabions require standard hand tools. The process is relatively simple and labor-intensive, often requiring less specialized equipment than concrete construction, contributing to lower overall project costs and faster deployment.

Conclusion

The PVC Coated Hexagonal Gabion represents a pinnacle in modern geo-engineering solutions, offering an unparalleled blend of strength, flexibility, and extreme durability. Its advanced material science, rigorous manufacturing process, and proven performance in diverse and challenging environments make it an indispensable asset for critical infrastructure projects, from river training and coastal defense to highway stabilization and industrial containment. For B2B decision-makers and engineering professionals, investing in these high-performance gabion systems translates into long-term cost savings, enhanced structural resilience, reduced maintenance burdens, and a positive environmental footprint. As the demand for sustainable and robust infrastructure continues to grow globally, the strategic importance of PVC-coated hexagonal gabions will only escalate, cementing their role as a foundational element for resilient development.

References

- ASTM A975-97. Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Carbon Steel Wire or Metallic-Coated Carbon Steel Wire With Poly(Vinyl Chloride) (PVC) Coating). ASTM International.

- EN 10223-3:2013. Steel wire and wire products for fencing and netting - Hexagonal steel wire netting for civil engineering purposes. European Committee for Standardization.

- Maccaferri, Officine. Gabion Technical Guide. (A well-known gabion manufacturer's technical publication providing detailed specifications and application guidance.)

- FHWA-SA-96-038. Design Guidelines for the Use of Gabions. Federal Highway Administration, U.S. Department of Transportation. (Provides engineering principles for gabion structure design.)