What Is Welded Wire Mesh?

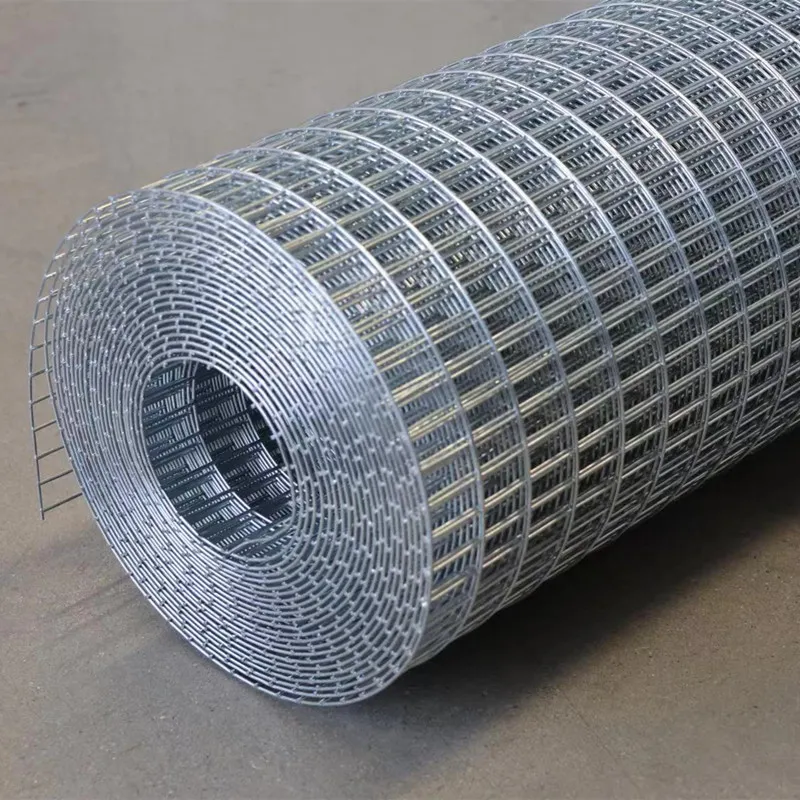

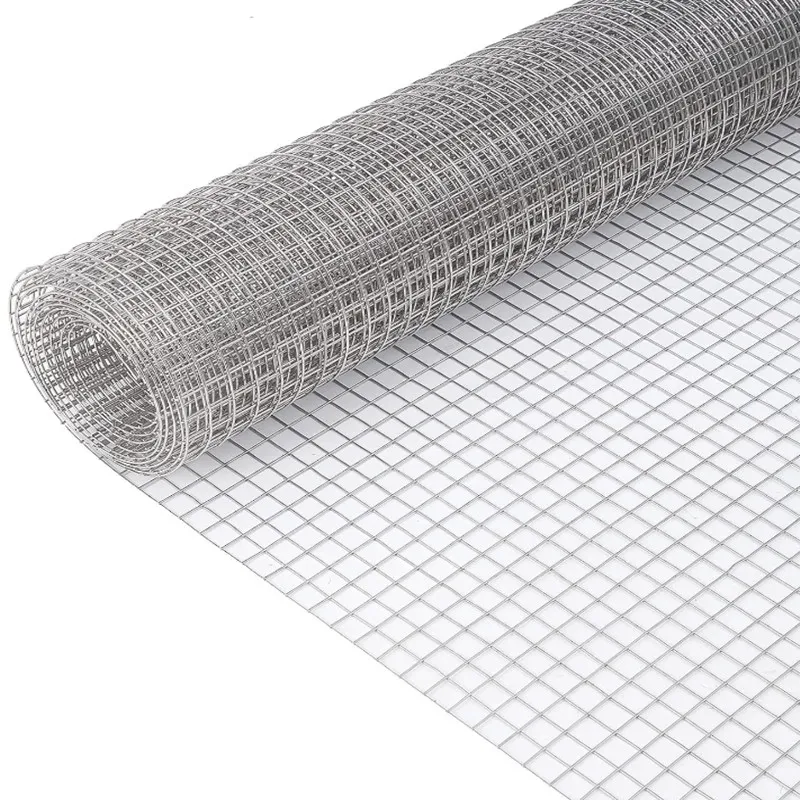

Welded Wire Mesh is a type of fencing material made from high-quality steel wires that are welded together at each intersection to form a grid. The wires are typically arranged in a square or rectangular pattern, creating a uniform mesh structure. The mesh is manufactured by welding the vertical and horizontal wires at the intersections using high heat and pressure, resulting in a strong, stable product.

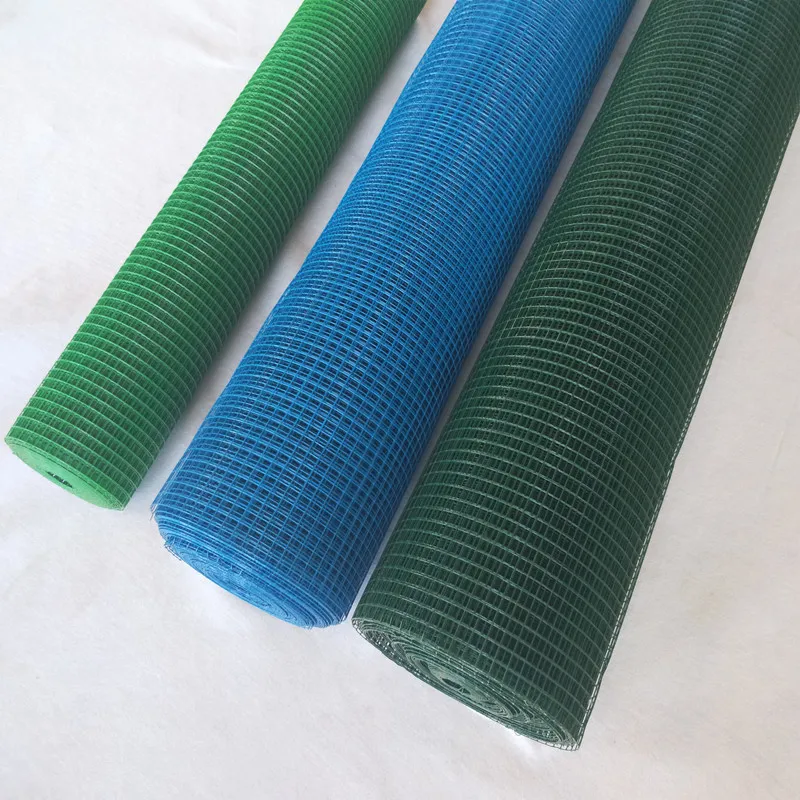

Welded Wire Mesh is commonly used in a variety of applications, such as fencing, reinforcement in concrete, animal enclosures, and industrial safety barriers. It is available in various wire diameters, mesh sizes, and sheet dimensions, offering flexibility for different needs. To enhance its durability and resistance to corrosion, Welded Wire Mesh is often coated with protective layers such as hot-dip galvanizing or PVC, making it ideal for outdoor environments where weather resistance is crucial.

The primary advantages of Welded Wire Mesh include its high strength, ease of installation, and minimal maintenance requirements. It is resistant to deformation and provides a secure barrier, preventing unauthorized access or intrusion. Additionally, its open grid design allows for good visibility and airflow, making it an ideal choice for a wide range of commercial, industrial, and residential applications.

Why Is Welded Wire So Expensive?

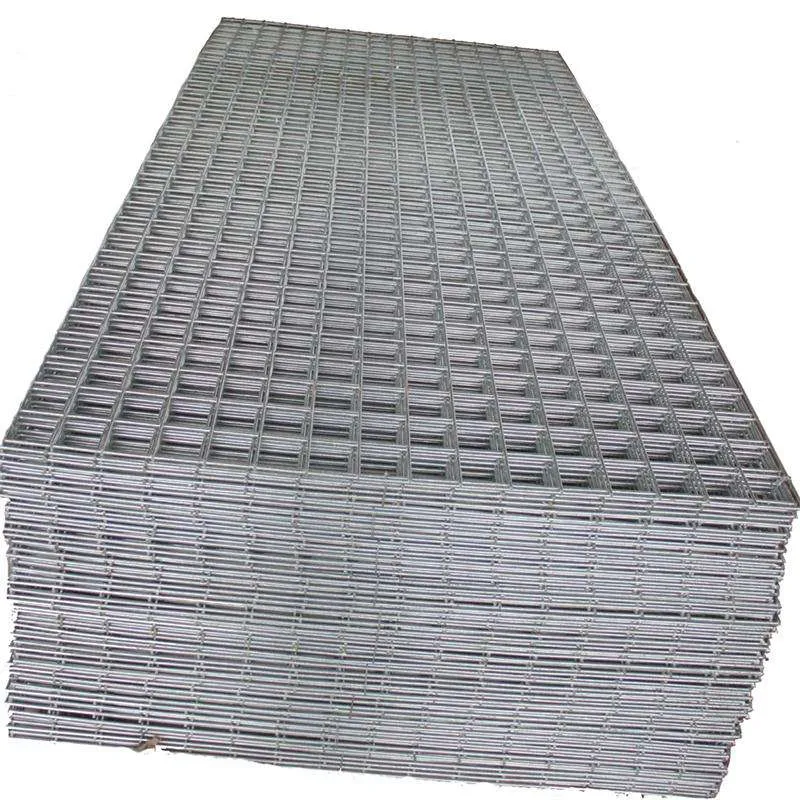

Welded Wire Mesh can be expensive due to several factors related to its manufacturing process, material quality, and durability. First, the production of welded wire mesh involves a detailed and labor-intensive process where steel wires are precisely welded together at every intersection. This requires specialized machinery and skilled labor to ensure the grid structure is uniform and strong.

Another significant cost factor is the high-quality raw materials used, typically steel, which is subject to fluctuating market prices. The thickness of the wire and the type of coating (e.g., galvanized or PVC-coated) further increase costs. Coatings are applied to provide corrosion resistance, making the mesh more durable for outdoor and industrial applications, but this additional treatment adds to the overall price.

The welding process itself also requires a considerable amount of energy, especially for large sheets of mesh. Furthermore, the finished product undergoes quality control checks to ensure consistency and strength, which adds to manufacturing costs.

Lastly, welded wire mesh is a highly durable and long-lasting material, offering better performance and longevity than alternatives like chain-link fencing. The upfront cost is offset by the mesh's resilience, reducing the need for frequent replacements or maintenance. As a result, the initial expense can be justified by the long-term value and reliability of the product.