What Is Woven Wire Mesh Used For?

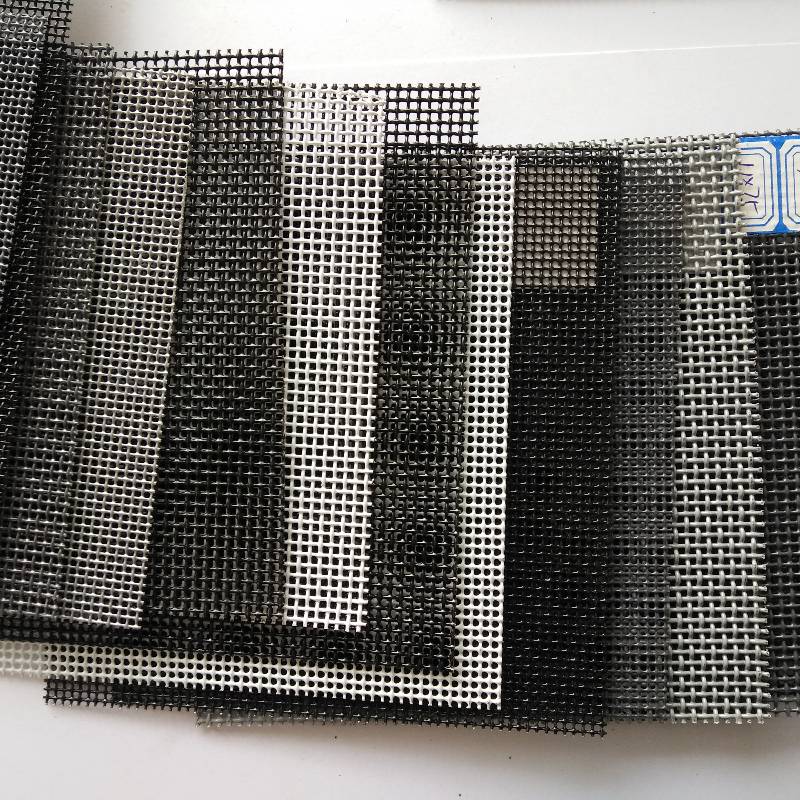

Woven Wire Mesh is a highly versatile material used in a wide range of applications across various industries. One of its primary uses is in filtration systems, where it serves as a durable screen for separating particles in industries like food processing, pharmaceuticals, and mining. Its uniform mesh openings make it ideal for applications requiring precise filtration, such as sifting and sorting materials.

In construction and security fencing, woven wire mesh is widely used for creating sturdy, reliable barriers. It is commonly seen in animal enclosures, as it provides a secure yet open structure that allows for visibility and ventilation. Additionally, it is used for reinforcing concrete in construction projects, helping to improve the strength and durability of buildings, roads, and other infrastructure.

The material is also popular in decorative applications, such as in architecture, where it can be used for facades, partitions, or custom-designed structures. Woven wire mesh is lightweight yet strong, resistant to wear and corrosion, and offers good visibility and airflow, making it suitable for industrial screens, gates, and safety barriers. Its adaptability, durability, and cost-effectiveness make it an essential material in a variety of commercial, industrial, and residential settings.

What Is The Difference Between Welded And Woven Mesh?

The main difference between welded mesh and woven mesh lies in how the wires are joined and their subsequent applications.

Welded mesh is made by electrically welding the intersections of the vertical and horizontal wires at every point, creating a rigid, fixed grid structure. This process results in a strong, stable mesh with precise, uniform openings. Welded mesh is typically used in applications that require high strength, such as security fencing, reinforced concrete, and industrial panels. Its rigid structure provides excellent resistance to deformation, making it ideal for structural integrity in demanding environments.

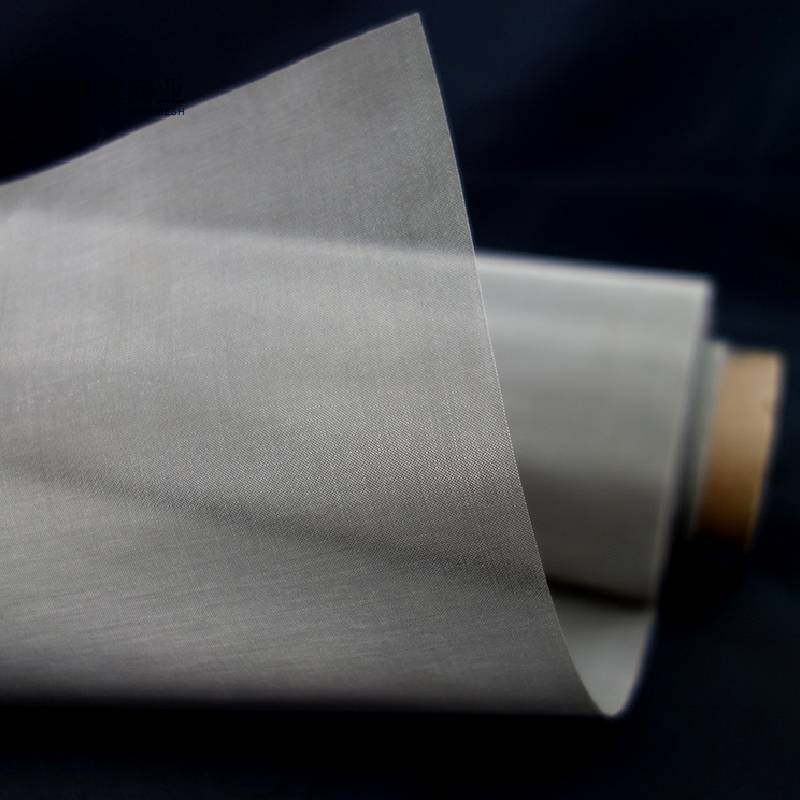

On the other hand, woven mesh is created by interlacing the vertical and horizontal wires in a crisscross pattern, without welding. This results in a more flexible and adaptable mesh, often used in applications like filtration, sifting, and protective barriers. Woven mesh allows for more customization in terms of wire diameter and mesh size and is ideal for screens, sieves, and other lightweight applications where flexibility is important.

In summary, welded mesh offers more rigidity and strength, while woven mesh provides flexibility and is suited for applications requiring lighter, more adaptable structures.