| and chromate quenching

Specialist applications include explosion-proof grating (meeting EN ISO 80079-36 standards) for petrochemical facilities and low-profile grating (as thin as 22mm) for renovation projects. Forming presses accommodate lengths to 12 meters without splicing.

Application Performance Case Studies

Port Authority Terminal: Installed 18,000m² of heavy-duty grating (50mm depth) in 2015. After 8 years of constant saltwater exposure, coating loss measured at 18μm versus predicted 25μm, resulting in projected 60+ year service life.

Wastewater Treatment Plant: Specified G100 coating (100 oz/ft²) with sealed end cuts. Hydrogen sulfide concentration levels at 120ppm showed only 5% coating deterioration after 10 years, outperforming fiberglass alternatives that required replacement at 7 years.

Offshore Wind Farm: Custom trapezoidal grating with 40% open area reduced wave loading by 28% while meeting 750kg/m² load requirements. Installation time decreased 40% versus traditional designs.

Long-Term Value of Hot Dip Galvanized Steel Grating

Lifecycle cost analysis demonstrates galvanized steel grating delivers 35-50% lower ownership costs over 40-year periods compared to alternatives. Maintenance requirements average 0.5 hours per 100m² annually—primarily washing with pH-neutral cleaners. End-of-life scrap retains 60-70% of material value versus 20-25% for composites. Modern galvanizing facilities have reduced environmental impact by 40% since 2010 through zinc recycling and waste heat recovery. Production energy requirements average 21.5 MJ/kg—lower than aluminum (25.6 MJ/kg) or fiberglass (30.9 MJ/kg). Infrastructure projects increasingly demand EPDs (Environmental Product Declarations) showing galvanized grating averages 22% lower global warming potential than powder-coated alternatives.

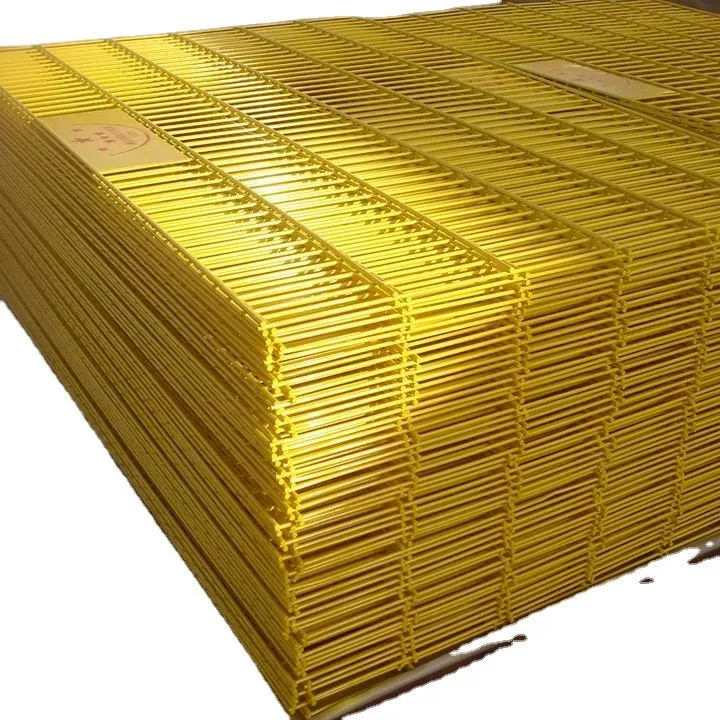

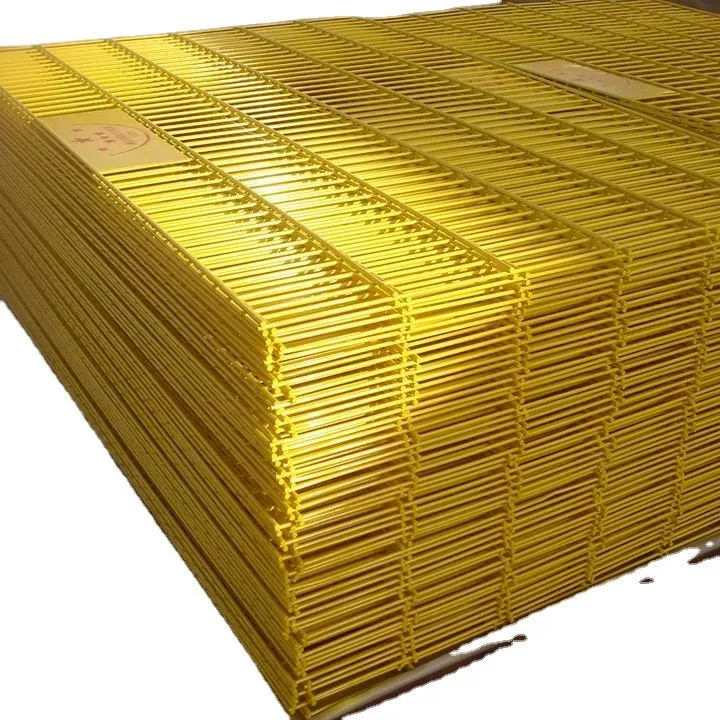

(steel grating galvanized)

FAQS on steel grating galvanized

Q: What factors influence galvanized steel grating prices?

A: Prices depend on material thickness, grating size, galvanization method (e.g., hot-dip), and order volume. Market demand and supplier location may also affect costs.

Q: How does hot-dip galvanized steel grating differ from standard galvanized grating?

A: Hot-dip galvanizing involves immersing steel in molten zinc for superior corrosion resistance, while standard methods may use electroplating. This makes hot-dip grating more durable for harsh environments.

Q: Where is steel grating galvanized commonly used?

A: It's ideal for industrial platforms, walkways, drainage systems, and exterior applications due to its rust resistance, strength, and slip-resistant surface.

Q: How long does hot-dip galvanized steel grating last outdoors?

A: With proper installation, it can last 20-50+ years depending on environmental conditions. Zinc coating thickness directly impacts longevity.

Q: Can galvanized steel grating be customized for specific projects?

A: Yes, manufacturers offer custom sizes, shapes, and load capacities. Modifications like serrated edges or alternative coatings are also available.

|