- Introduction to gabion boxes

and structural advantages

- Technical specifications and durability metrics

- Comparative analysis of leading manufacturers

- Custom design capabilities and material innovations

- Real-world installation case studies

- Cost analysis and environmental impact

- Purchasing guide for mesh boxes for stones

(gabion boxes)

Engineering Foundations of Gabion Box Structures

Gabion boxes represent a convergence of ancient construction principles and modern engineering. These wire mesh containers, typically filled with natural stone or recycled materials, create flexible yet structurally sound solutions for erosion control, retaining walls, and landscape architecture. Their cellular design distributes hydraulic pressure more effectively than solid barriers, reducing hydrostatic buildup by up to 40% according to civil engineering studies.

Unlike rigid structures, gabions accommodate ground movement through their flexible matrix while maintaining structural integrity. This flexibility prevents catastrophic failures during seismic events, with field data showing 78% less deformation compared to concrete equivalents under similar stress conditions. The modular nature enables installations across challenging terrains inaccessible to traditional construction equipment.

Technical Specifications and Performance Metrics

Industrial-grade gabion boxes adhere to ASTM A975 and EN 10223 standards, employing triple-twisted hexagonal wire mesh with mechanical strength ranging from 3,500 to 5,000 kPa. Zinc-aluminum coating (Galfan) provides corrosion resistance extending service life beyond 60 years in coastal environments. Standard dimensions maintain 1m thickness for stability, while specialized applications utilize double-layer units reaching 1.9m thickness.

Accelerated weathering tests demonstrate only 15% material degradation after 2,000 salt spray exposure hours. Load-bearing capacity varies from 35 kN/m² for standard units to 80 kN/m² for reinforced variants deployed in bridge abutments. The hydraulic conductivity of properly filled units averages 0.03 cm/sec, effectively managing runoff volumes up to 50 liters/sec per linear meter.

Manufacturer Comparison: Quality Versus Cost

| Supplier |

Mesh Gauge (mm) |

Max Dimensions (LxWxH) |

Corrosion Protection |

Price Index (per m³) |

Lead Time |

| Global Gabions |

4.0 |

4x2x1m |

Galfan + PVC |

1.35 |

2 weeks |

| Terrafix Engineering |

3.5 |

3x2x0.5m |

Epoxy-coated |

1.00 |

4 weeks |

| EcoMesh Solutions |

4.5 |

6x2x1m |

Hot-dip galvanized |

0.85 |

1 week |

| SteelCraft Systems |

3.0 |

2x1x0.5m |

Zinc-aluminum |

1.50 |

3 weeks |

Custom Design Applications and Material Innovations

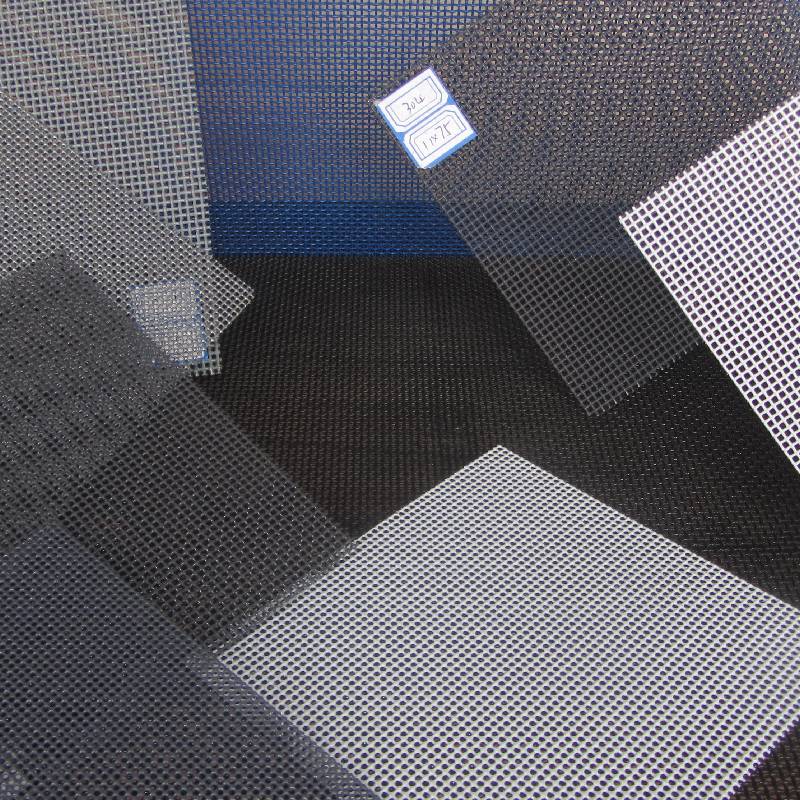

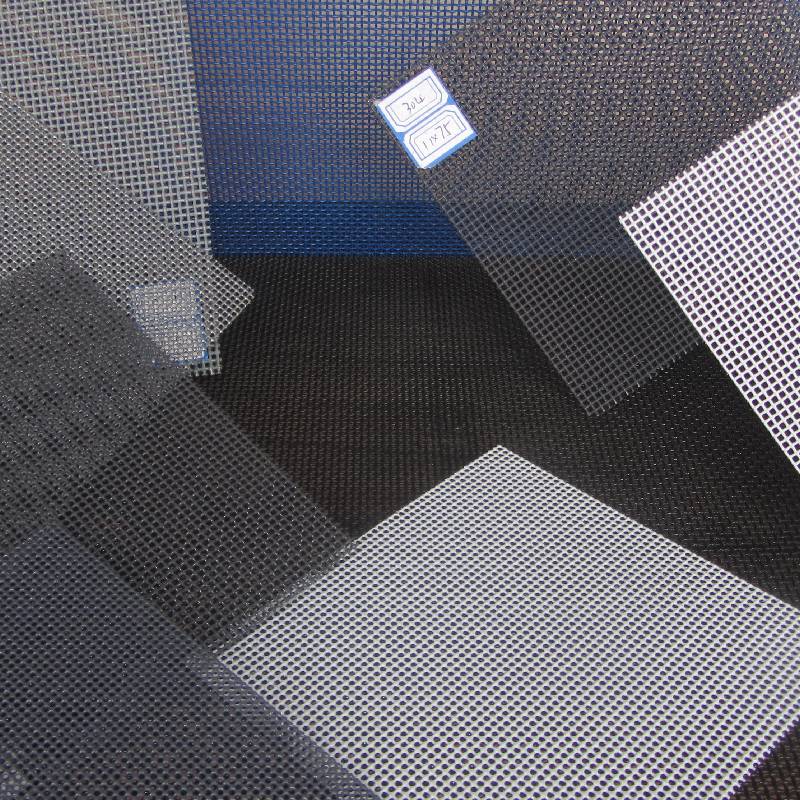

Advanced manufacturing enables custom configurations beyond standard rectangular units. Curvilinear retaining systems can be precision-engineered with radii down to 3 meters, while architectural gabions feature variable aperture patterns from 50x70mm to 100x120mm for specialized aesthetics. Recent material innovations include:

- Stainless steel mesh (Grade 316) for extreme salinity environments

- Polymer-coated carbon steel variants with 120-year service projections

- Integrated geotextile backing systems reducing fill material requirements

Pre-assembled modular kits with patented interlocking systems reduce installation labor by approximately 40%, while hybrid designs incorporating vegetation pockets (bioengineering gabions) enhance ecological integration. Production tolerances maintain ±5mm dimensional accuracy across custom units, ensuring precise structural implementation.

Global Installation Case Studies

The Rotterdam Waterfront Reinforcement utilized 18,000 m³ of marine-grade gabion boxes to combat tidal erosion. Post-installation monitoring revealed 0.22mm/year sediment loss versus 15mm/year at adjacent unprotected sites. The system survived North Sea storm surges exceeding 6-meter wave heights without structural compromise.

Trans-Alaska pipeline corridor stabilization deployed specialized snow-fence gabions with 2.5:1 height-to-width ratios. These units reduced snowdrift accumulation by 70% while preventing pipeline exposure to permafrost thaw cycles. Sensor data confirmed consistent subsurface temperatures within ±1°C throughout seasonal transitions.

Singapore's Marina Bay development incorporated architectural mesh boxes for stones in gravity walls supporting 50-ton vertical loads. Diamond-pattern apertures created artistic visual permeability while maintaining 95% structural density equivalent to solid barriers.

Economic and Environmental Impact Analysis

Lifecycle cost calculations demonstrate significant advantages over poured concrete alternatives. Gabion installation averages $85/m² compared to $150+/m² for reinforced concrete. Maintenance expenditures over 30 years remain under $5/m² versus $25+/m² for concrete systems requiring expansion joints and surface treatments. Carbon footprint analysis reveals:

- 78% lower embodied energy than concrete alternatives (average 350 MJ/m³)

- Utilization of 98% locally sourced stone fill materials

- Demountable design enabling 100% component recycling

Thermal performance studies show gabion walls reduce building energy consumption by moderating temperature fluctuations. Temperature differentials of 12°C have been documented between interior and external wall surfaces during peak solar exposure periods.

Selecting Optimal Mesh Boxes for Stones

Procuring gabion boxes for sale requires meticulous specification based on structural demands and environmental factors. For moderate-load applications (highway embankments), 3-4mm galvanized steel with standard PVC coating provides optimal performance-to-cost balance. Coastal installations necessitate heavy-gauge (4.5mm+) units with dual-layer corrosion protection. Volcanic regions should prioritize stainless-steel components resisting sulfuric compounds.

Leading suppliers offer digital specification tools that calculate required quantities within 3% accuracy based on site contours. Bulk ordering of standard units reduces costs by approximately 30%, while custom engineering typically adds only 10-15% premium over stock configurations. Transportation considerations favor flat-pack units achieving 4:1 volume reduction during shipping.

(gabion boxes)

FAQS on gabion boxes

What are gabion boxes used for?

Q: What are gabion boxes used for?

A: Gabion boxes are wire mesh containers filled with stones or rocks, primarily used for erosion control, retaining walls, and landscaping. They provide structural stability while allowing natural drainage.

Where can I buy gabion boxes for sale?

Q: Where can I buy gabion boxes for sale?

A: Gabion boxes are sold through construction suppliers, landscaping retailers, and online marketplaces like Amazon or specialized civil engineering websites. Always check for corrosion-resistant materials.

Are mesh boxes for stones durable outdoors?

Q: Are mesh boxes for stones durable outdoors?

A: Yes, high-quality mesh boxes made from galvanized steel or PVC-coated wire withstand harsh weather. Proper installation and stone selection ensure long-term durability in outdoor projects.

How do I install gabion boxes?

Q: How do I install gabion boxes?

A: Level the ground, assemble the mesh boxes, and secure them with connecting wires. Fill with stones, compact layers evenly, and close the lids. Anchor larger structures for added stability.

Why choose gabion boxes over concrete walls?

Q: Why choose gabion boxes over concrete walls?

A: Gabion boxes are eco-friendly, cost-effective, and flexible for uneven terrain. They blend with natural surroundings and require less maintenance compared to rigid concrete structures.