In the bustling world of construction and industrial applications, wire mesh has emerged as a polymer of choice due to its versatility, strength, and adaptability. Wire mesh manufacturers play a pivotal role in the supply chain, crafting innovative solutions that cater to sectors ranging from architecture to agricultural management. For those seeking top-quality products from reliable wire mesh manufacturers, understanding the intricacies of manufacturing processes, industry standards, and applications is essential.

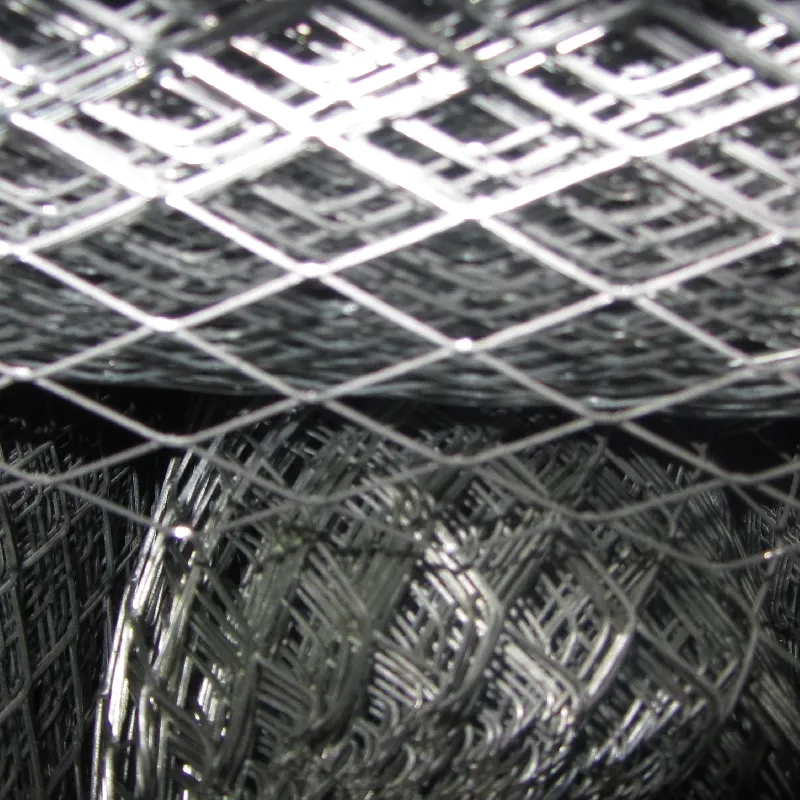

Wire mesh is a multipurpose material made by interlacing wires to create a consistent pattern of open spaces. By varying the material, gauge, and weave type, manufacturers can produce wire mesh that meets specific functional demands. The art of manufacturing such precise materials requires expertise and a deep understanding of both raw materials and end-user requirements.

The first aspect of finding a reputable wire mesh manufacturer lies in their expertise. A proficient manufacturer is well-versed in different manufacturing techniques such as woven, welded, or knurled meshes. They can convey the subtle but significant differences between options like stainless steel, galvanized steel, brass, or aluminum meshes. The choice of material affects the mesh’s durability, corrosion resistance, and suitability for outdoor or high-temperature applications.

Professional manufacturers invest in state-of-the-art machinery that ensures the production of wire mesh with uniformity and precision. Such investment not only improves production efficiency but also guarantees the longevity of the mesh, instilling trust among clients who bank on the product’s reliability in high-stake projects. This adherence to quality standards is often highlighted by compliance with international certifications such as ISO, which attests to the company’s commitment to maintaining high-quality operations and products.

Experience speaks volumes in the industry of wire mesh manufacturing. Seasoned manufacturers bring a wealth of knowledge accumulated through years of supplying to diverse industries. This experience enables them to provide customized solutions that cater to niche requirements—be it for fencing, filtration, or reinforcement. A company with a notable history is often open to sharing case studies or testimonials that showcase their ability to tackle challenging projects successfully, thus enhancing their authoritativeness in the market.

Trustworthiness in a wire mesh manufacturer can be assessed by their customer service and post-sales support. Manufacturers who offer comprehensive support, include installation guidelines, troubleshooting advice, and regular maintenance tips, help in extending the product's lifespan and performance. Clients can feel secure in their investment, knowing that the manufacturer stands behind their product offering long-term support.

Moreover, reputable manufacturers often engage in sustainability practices by minimizing waste during production and ethically sourcing raw materials. As more businesses align themselves with eco-friendly operations, partnering with a manufacturer who prioritizes environmental responsibility can enhance a brand’s reputation and appeal.

Finally, in navigating the selection of the right manufacturer, potential clients benefit from transparency and open communication. An accessible and informative website operated by the manufacturer signals their commitment to customer education, providing insights into the specifics of their offerings, innovations, and industry advancements.

Selecting the right wire mesh manufacturer extends beyond mere product quality; it encompasses professionalism, comprehensive expertise, consistent communication, and a proven track record of client satisfaction. By focusing on these attributes, companies can find partners who not only supply materials but actively contribute to the success of their applications.

RELATED PRODUCTS