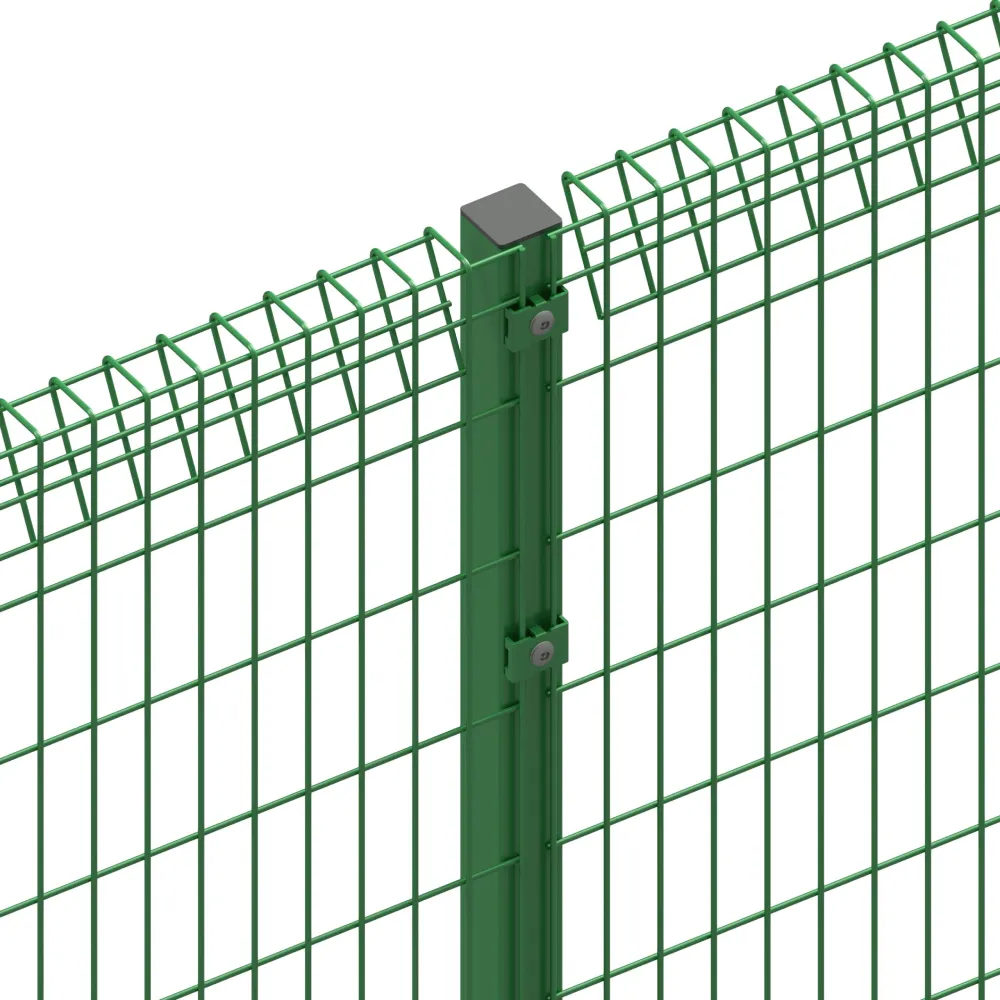

If you spend enough time around parks, schools, and tidy industrial estates, you start recognizing the quiet workhorses. One of them is the Roll Top Fence—the one with the safety hem rolled at the top and bottom so nobody snags a hoodie or a football. It looks simple. It isn’t. In fact, the trend in the last three years has been a shift toward thicker wires, better powder systems, and smarter clamps that reduce rattle. And yes, people notice—especially facilities managers who don’t want callbacks.

Common uses? Schools, playgrounds, community parks, residential perimeters, light industrial sites, and sports grounds. The rounded edges are, to be honest, the difference between “safe” and “nearly safe.” Many customers say they chose the Roll Top Fence because it looks friendly without compromising perimeter lines. It also plays nicely with landscaping—clean sightlines, no intimidating spikes.

Panels are typically low-carbon steel wire, welded at every junction, then hot-dip galvanized and/or powder coated. The rolled hems are formed to eliminate sharp edges. Posts are usually SHS with clamp bars or brackets. Below is a realistic spec snapshot I often see on compliant projects:

| Item | Typical Spec (≈ / around) |

|---|---|

| Panel height x width | 1200–2400 mm x 2500–3000 mm |

| Mesh aperture | 50 x 150 mm (±2 mm) |

| Wire diameter | 4.0–6.0 mm (core) |

| Finish options | Hot-dip galvanized per ASTM A123; powder coat per ISO 12944 (C3–C4) real-world may vary |

| Posts | 60x60 or 80x60 SHS, wall 2.5–3.0 mm |

| Fasteners | Clamps with M8 anti-tamper bolts, SS304 fixings |

Materials: low-carbon steel wire rod → drawing → straightening → welding (resistance welders) → roll forming hems → galvanizing (HDG) → chemical pretreatment → powder coating → curing → inspection.

Testing: zinc thickness per ASTM A123 or EN 10244-2, coating adhesion per ASTM D3359, salt spray per ASTM B117 (≥500–1000 h target for C3–C4), bend/impact checks, and dimensional tolerance audits. Service life? Around 10–25 years depending on environment class and maintenance.

Manufacturers in Hebei’s fence corridor have dialed this product in. One example operates out of the East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui City, Hebei Province—close to galvanizing lines and export logistics. Here’s a broad comparison I use when advising buyers:

| Vendor Type | Strengths | Watch-outs |

|---|---|---|

| Hebei manufacturer (e.g., Tike Metal) | Competitive pricing; in-house HDG; customization; fast lead times. | Specify standards clearly; request test reports. |

| Local fabricator | Site support; small-batch agility. | Higher unit cost; limited coatings. |

| Import aggregator | Single-source logistics; broad catalog. | Spec variability; opaque origin details. |

| Premium EU brand | Top-tier coatings; documented compliance. | Budget impact; longer lead times. |

Heights (1.2–2.4 m), wire gauges (4–6 mm), RAL colors (popular: 6005, 7016, 9005), bespoke brackets, slope panels for gradients, and security add-ons (bottom flat bar, tamper-proof nuts). Actually, many schools request matching pedestrian gates with soft-close hinges—worth budgeting.

Community park, coastal zone (C4): 6.0 mm wire, HDG + duplex powder. 1,000 h ASTM B117 achieved; zero blistering at 18 months. Park staff, somewhat surprised, reported no panel rattles.

Primary school, inland (C3): 1.8 m high Roll Top Fence, 50x150 mesh, 60x60 posts. Incidents dropped (anecdotal) after clearer boundaries were set. Maintenance team liked the clamp bar system—fewer loose bits.

To be honest, choosing a Roll Top Fence comes down to environment class, wire gauge, and consistency in coatings. Ask for drawings, MTCs, zinc thickness data, and adhesion/salt-spray reports before you sign. Simple, but it saves headaches.

RELATED PRODUCTS