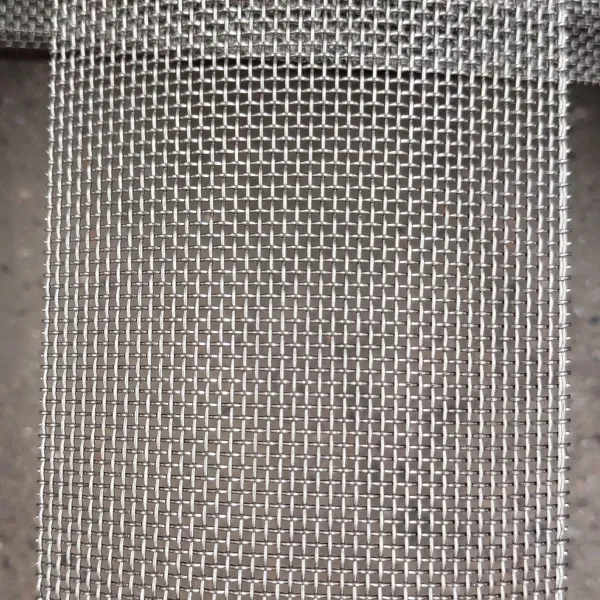

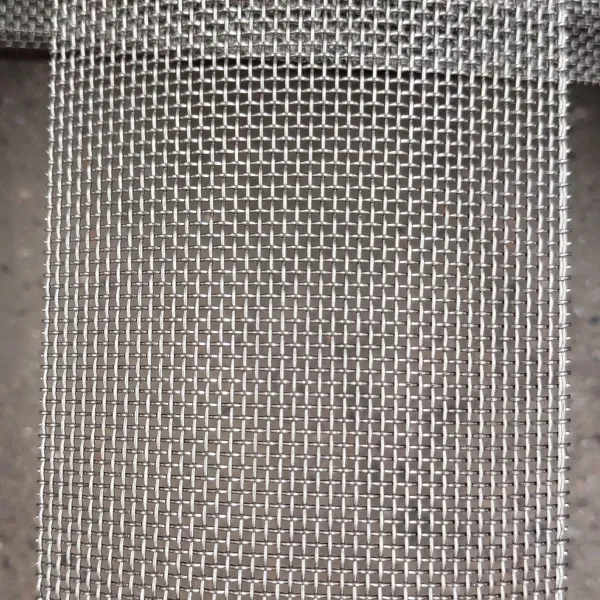

Welded gabion mesh has emerged as a crucial element in modern construction and landscaping, offering both functional and aesthetic benefits. Constructed from high-quality steel wire, which is then galvanized to ensure longevity and resistance to corrosion, welded gabion meshes are assemblies of wire or mesh boxes filled with organic materials like stones or sand. The application of these structures ranges from retaining walls, erosion control, and decorative features to their usage in various infrastructure projects. This article delves into the versatile applications and advantages of welded gabion mesh, based on both industry expertise and real-world experiences.

A fundamental advantage of welded gabion mesh is its unparalleled durability. Unlike traditional materials that may suffer wear and tear due to weather conditions, welded gabion mesh boasts a robust structure due to its galvanized wire fabrication.

Such resilience is particularly evident in projects aimed at erosion control. For instance, in areas prone to heavy rainfall or flooding, the implementation of gabion barriers can prove life-saving. Such structures effectively absorb and dissipate energy from flowing water, minimizing erosion of the soil beneath and around them.

From an aesthetic viewpoint, welded gabion meshes offer flexibility and creativity to landscape architects and designers. The visual appeal of these features cannot be understated, as they can be filled with a variety of materials to complement surrounding environments. Public parks and gardens often employ gabion mesh for creating striking rock walls or benches, combining functionality with style. This ability to blend into different settings has made gabion mesh a popular choice for both urban and rural landscapes.

In terms of environmental impact, welded gabion meshes stand out as an environmentally friendly option. Made from natural, recyclable materials, these structures do not contribute to pollution. Their permeable nature allows water to pass through, reducing runoff and promoting natural drainage. This characteristic is beneficial in urban environments where traditional impervious surfaces often lead to drainage issues. Furthermore, the filling material can often be sourced locally, reducing the carbon footprint associated with transporting building materials over long distances.

Professional experiences from the construction industry highlight the efficiency and cost-effectiveness of using welded gabion meshes. Unlike concrete walls, which require significant time and labor to set up, gabion installations are relatively quick and straightforward. Engineers appreciate their modular nature, allowing for easy adjustments during construction to address unforeseen challenges or changes in a project scope. This adaptability is complimented by low maintenance costs, as the sturdy materials require little upkeep once installed.

welded gabion mesh

The versatility of welded gabion mesh extends to its use in infrastructure projects. Roads and highways, often subjected to various environmental stresses, can benefit from the supportive properties of gabion wall reinforcements. Their ability to conform to the natural movement of earth is particularly advantageous when dealing with slopes adjacent to roadways, where the prevention of landslides or soil erosion is paramount. Similarly, these structures are utilized in bridge abutments and riverbank protections, providing stability while blending into the natural scenery.

From an authoritative standpoint, numerous case studies and academic research underscore the effectiveness of welded gabion meshes. Reports document successful applications in regions with diverse climate conditions, affirming their reliability. Furthermore, experts in environmental engineering and construction have endorsed their use, often recommending them for projects where both structural integrity and environmental considerations are priorities.

Trustworthiness in the use of welded gabion mesh is also backed by international standards and certifications. Manufacturers adhering to such standards provide assurance that their products meet the highest quality requirements, ensuring peace of mind for both project managers and end-users. This confidence is further bolstered by positive testimonials and reviews from clients and communities benefiting from gabion mesh installations.

In conclusion, the adoption of welded gabion mesh in construction provides a confluence of durability, environmental sustainability, and aesthetic flexibility. Its multifaceted application across various domains signifies its importance in contemporary engineering and design. Expertise in the field corroborates its benefits, making it a preferred choice for projects demanding reliable and low-impact solutions. With ongoing advancements and innovations, welded gabion mesh continues to affirm its position as an indispensable resource in modern construction and landscaping.