If you’ve ever tried to choose fencing for a plant expansion or a farm perimeter, you know the paradox: simple product, dizzying options. I’ve walked yards from Texas to Tangshan, and the same truth pops up—specs matter, but so do context and supplier discipline. Here’s the condensed insider’s tour.

- GBW vs. GAW: galvanized before weld (clean look) vs. after weld (better corrosion at nodes).

- PVC/PE powder-coated: color-coded per site branding; also reduces hand injuries, a small but real win.

- 358 anti-climb: 3"×0.5"×8 gauge (≈76.2×12.7 mm, 4.0 mm) for high security.

- Double-wire panels: 6/5/6 or 8/6/8 mm for rigidity along long runs.

- Stainless 304/316 for food plants or brine exposure (capex up, OPEX down).

- Temporary welded panels with feet for events and shutdown work.

Origin: East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui City, Hebei Province.

| Material | Low carbon steel wire (Q195); optional SS304/316 |

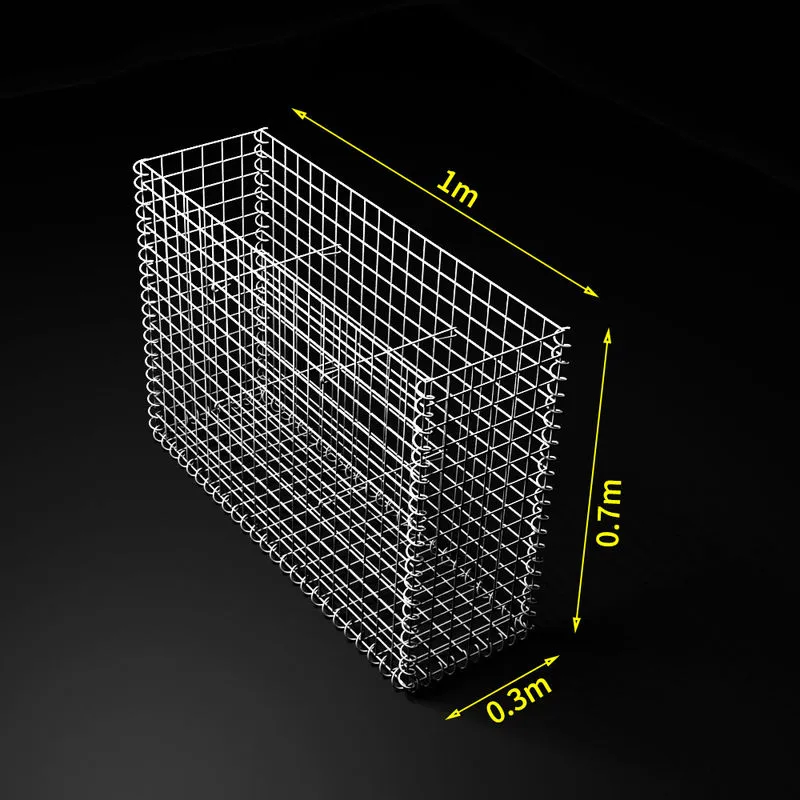

| Wire diameter | ≈2.5–5.0 mm (special 6/5/6 and 8/6/8 available) |

| Mesh aperture | 50×50, 50×100, 75×150, 76.2×12.7 mm (358), others on request |

| Panel/Roll size | Panels up to 2.5×3.0 m; rolls 0.9–1.8 m high, ≈30 m long |

| Coatings | Galv 60–275 g/m²; powder 60–100 μm; dual-coat optional |

| Mechanical | Tensile ≥ 450–550 MPa; weld shear per ASTM A1064 |

| Standards | ASTM A641/A1064, ISO 1461/9227, EN 10223-4 |

| Service life | ≈8–25 years (climate and maintenance dependent) |

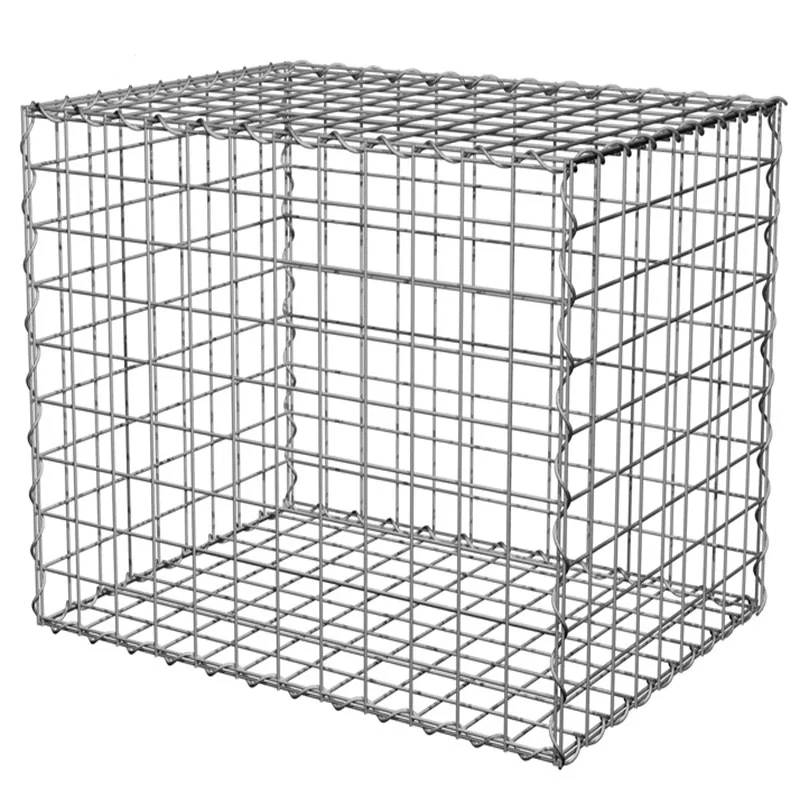

Industrial perimeters, substations, farms, kennels, gardens, highways, and data centers. Advantages customers mention: clean geometry (looks tidy), predictable wind load, quick installs with clips, and easy repairs—swap a panel, not a run. In coastal zones, I recommend dual-coat or 316 stainless; to be honest, cheaper spec creep shows up as rust at welds after year two.

| Vendor | Coating spec | Lead time | Notes |

|---|---|---|---|

| Tikemetal (factory) | Galv 60–275 g/m²; powder ≈80 μm | 10–20 days | ISO 9001; custom apertures; origin Hebei |

| Local distributor | Varies; often mid-spec | 1–7 days (stock) | Fast, limited customization |

| Generic import | Inconsistent; verify | 15–40 days | Check weld shear, coating certificates |

Aperture, wire gauge, post systems, and RAL color are the big four. Ask for salt-spray hours (≥500 h for powder-over-galv is a solid baseline), weld shear reports, and batch zinc certificates. Many customers say a small bump in coating spec paid for itself in year three maintenance they didn’t need.

Final tip: specify the mesh by wire diameter, aperture, and coating thickness, tie it to ASTM/ISO clauses, and request test data with the shipment. That’s how buyers keep Types Of Welded Wire Fencing projects on time—and rust off the balance sheet.

RELATED PRODUCTS