Steel grating heavy duty solutions have become indispensable in modern industrial environments due to their strength, durability, and versatility. Having spent over a decade in the materials engineering sector, I have encountered numerous applications where heavy-duty steel grating demonstrates its unrivaled superiority.

Steel grating is engineered to handle the toughest conditions, whether used for flooring, platforms, or walkways. I recall an experience with a large manufacturing plant where the floors were being replaced. Initially, the plant management considered traditional concrete flooring but ultimately opted for heavy-duty steel grating due to its robustness and excellent load-bearing capacity. This decision not only saved the company from future repair costs but also enhanced worker safety due to the slip-resistant surface of the grating.

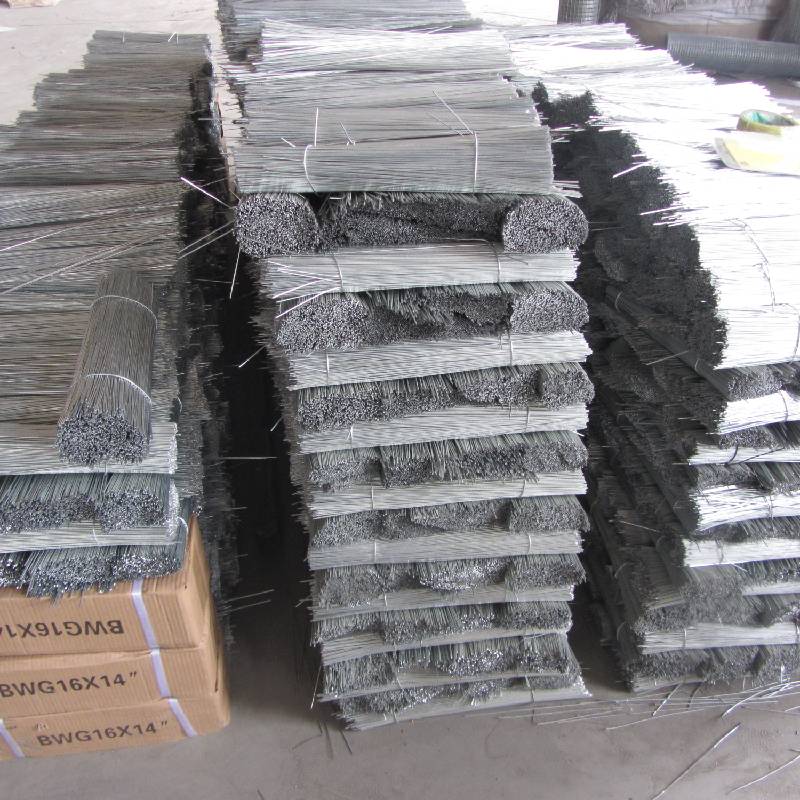

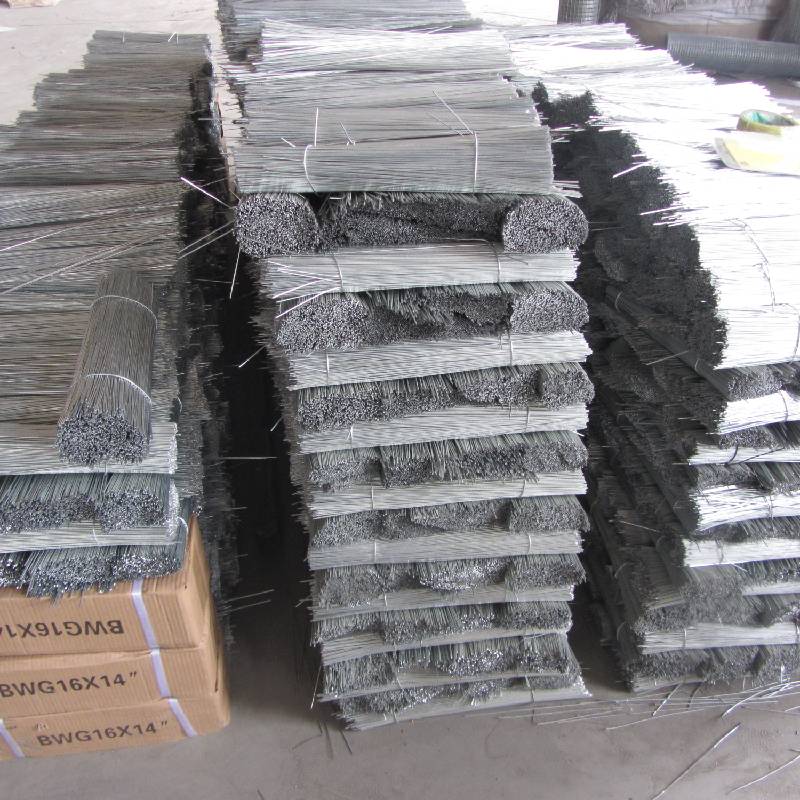

The expertise behind steel grating lies in its construction. Typically made from carbon steel, stainless steel, or aluminum, these gratings are manufactured either through welding or riveting. This intricate process involves aligning the load-bearing bars and crossbars to ensure a perfect balance between strength and weight distribution. The result is a product that can withstand heavy machinery and frequent vehicular movement without bending or breaking.

From a professional standpoint, heavy-duty steel grating stands out due to its adaptability to various environments. For instance, in corrosive settings like chemical plants or marine locations, stainless steel grating is highly recommended due to its corrosion-resistant properties. An authoritative study conducted by a renowned engineering institute demonstrated that high-grade stainless steel grating could endure harsh chemical exposure for more than two decades with minimal maintenance.

Furthermore, the trustworthiness of steel grating is evident from its widespread use in sectors such as oil and gas, waste management, and transportation. I recall a project in which an oil company required a durable grating solution for offshore platforms. The grating had to meet stringent safety standards to prevent slippage and handle extreme weather conditions. After careful consideration, the company installed heavy-duty steel grating, which has since performed beyond expectations, providing a secure and stable platform for workers and equipment alike.

steel grating heavy duty

Of note is the environmental sustainability of steel grating products. Steel is a recyclable material, and the production process increasingly incorporates eco-friendly methods. Steel grating manufacturers now utilize advanced techniques to reduce waste during the creation process, making heavy-duty steel grating not only a safe choice but also an environmentally conscious one.

Compared to other materials like wood or plastic, steel grating offers a substantial return on investment. While the initial cost may be higher, the long-term benefits, such as reduced maintenance needs and extended lifespan, make it a more cost-effective option. Industry experts have consistently advocated for its use, particularly in projects with a focus on sustainability and safety.

Selecting the right type of steel grating depends on several factors, including the specific application, environmental considerations, and budget constraints. For a project manager or engineer, understanding these elements is critical. I advise consulting with experienced professionals who can provide detailed assessments and recommend appropriate specifications tailored to individual project requirements.

In conclusion, heavy-duty steel grating is not just another industrial component; it represents a confluence of engineering ingenuity, practical application, and environmental responsibility. Whether in heavy machinery zones, offshore rigs, or pedestrian pathways, it offers unmatched performance and reliability. The next time you step onto a platform made of this remarkable material, remember the intricate science and expertise that make such robust and reliable surfaces possible.